Preparation method for three-dimensional graphene

A graphene, three-dimensional technology, applied in the field of preparation of self-supporting three-dimensional graphene, can solve problems such as inability to increase production, waste of ammonium chloride, poor self-foaming effect of glucose, etc., to achieve improved electrical transmission performance, good effect, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Three-dimensional graphene is prepared by using tryptophan as a precursor. The first step is to weigh a certain amount of tryptophan, and the second step is to raise the temperature to a specified temperature and keep it for a certain period of time to prepare a self-supporting three-dimensional graphene foam.

[0020] Step 1, weigh tryptophan and place it in the furnace body;

[0021] Step 2. Under an inert atmosphere, raise the temperature of the reaction system to 1000°C at 4°C / min, and keep it warm for 0.5h;

[0022] Step 3, the reaction furnace is cooled to room temperature, and after the reaction is completed, the sample is taken out.

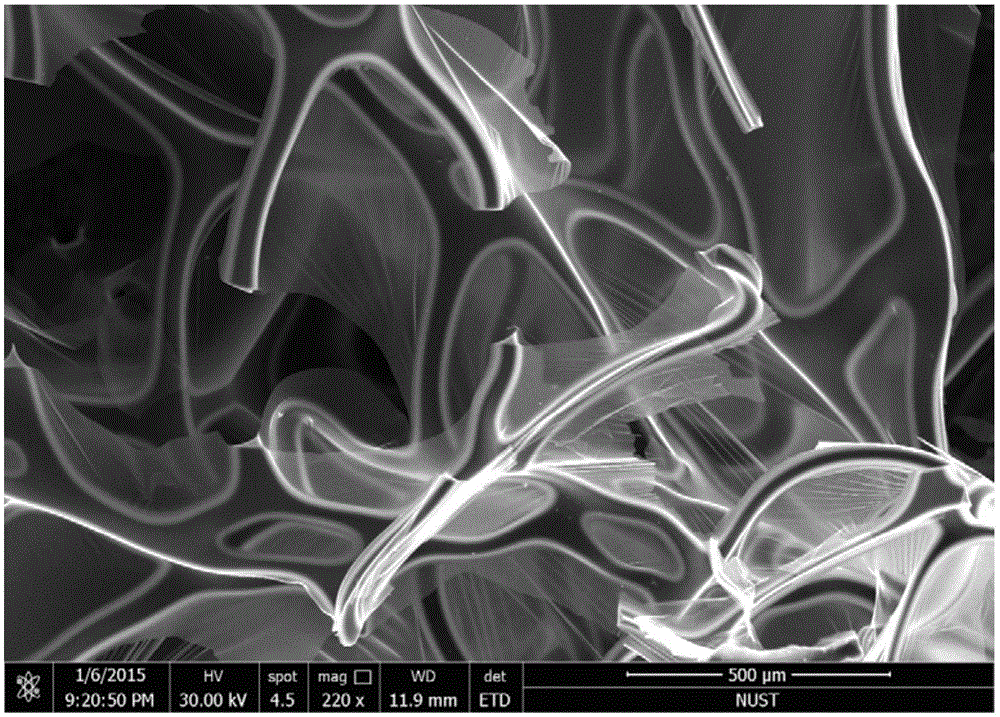

[0023] Optical and SEM characterization of the samples as figure 1 , 2 shown. The results show that, according to the process parameters of Example 1, the three-dimensional graphene with larger pores connected to each other, better light transmission, and self-supported by the carbon skeleton can be obtained.

Embodiment 2

[0025] Three-dimensional graphene is prepared by using tryptophan as a precursor. The first step is to weigh a certain amount of tryptophan, and the second step is to raise the temperature to a specified temperature and keep it for a certain period of time to prepare a self-supporting three-dimensional graphene foam.

[0026] Step 1, weigh tryptophan and place it in the furnace body;

[0027] Step 2. Under an inert atmosphere, raise the temperature of the reaction system to 1200°C at a rate of 6°C / min, and keep it warm for 2 hours;

[0028] Step 3, the reaction furnace is cooled to room temperature, and after the reaction is completed, the sample is taken out.

[0029] Carry out SEM, EDS characterization to sample with example 1.

Embodiment 3

[0031] Three-dimensional graphene is prepared by using tryptophan as a precursor. The first step is to weigh a certain amount of tryptophan, and the second step is to raise the temperature to a specified temperature and keep it for a certain period of time to prepare a self-supporting three-dimensional graphene foam.

[0032] Step 1, weigh tryptophan and place it in the furnace body;

[0033] Step 2. Under an inert atmosphere, raise the temperature of the reaction system to 1400°C at a rate of 10°C / min, and keep it warm for 5 hours;

[0034] Step 3, the reaction furnace is cooled to room temperature, and after the reaction is completed, the sample is taken out.

[0035] Carry out SEM, EDS characterization to sample with example 1.

[0036] In the present invention, tryptophan is used as a carbon source, and graphene is prepared by self-foaming at a high temperature, without a practical foaming agent and the foaming effect is better; since the precursor contains organic nitrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com