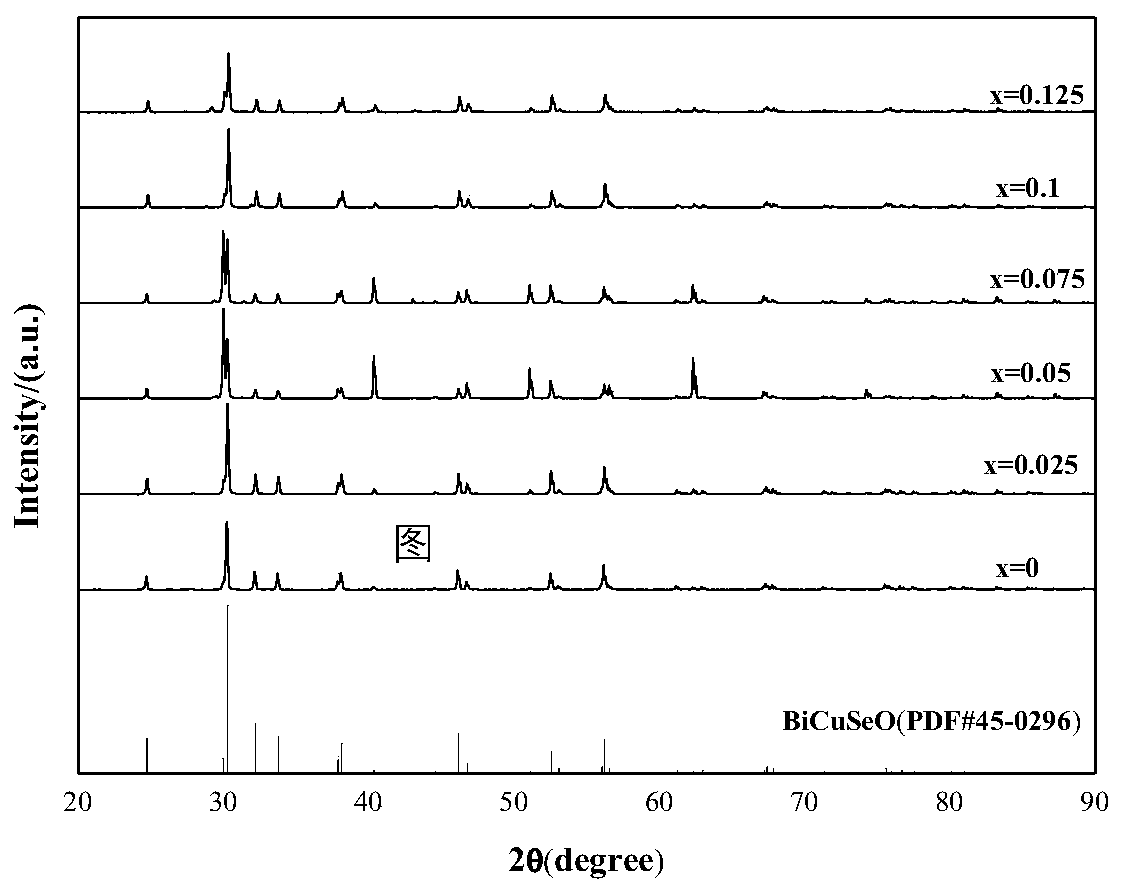

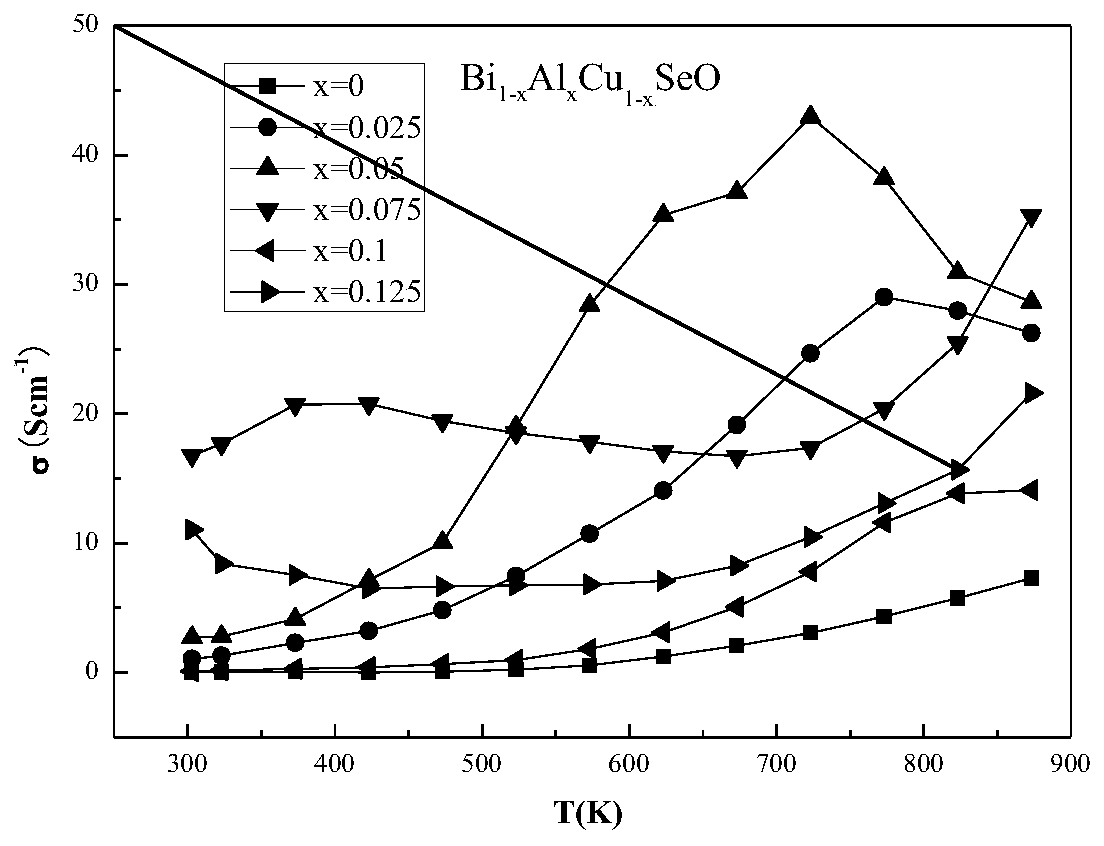

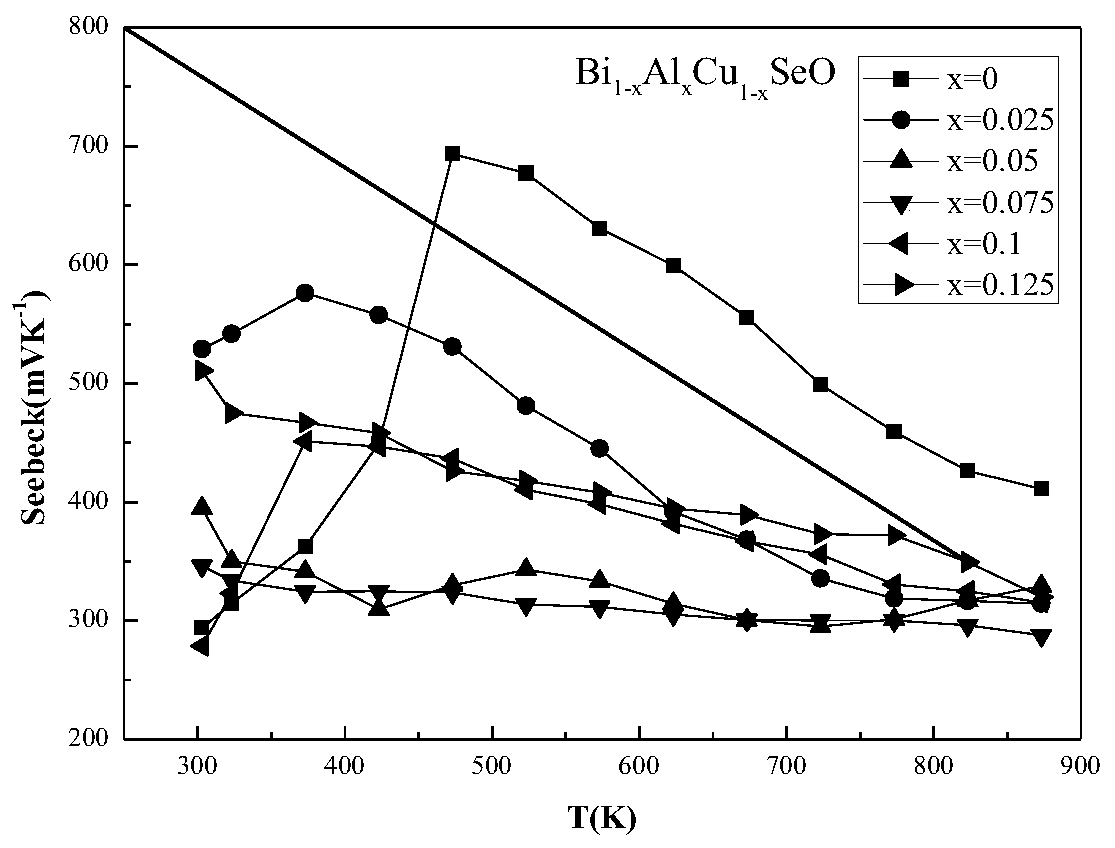

Al-doped Cu-deficient BiCuSeO-based thermoelectric material and preparation method thereof

A technology of thermoelectric materials and vacancy, which is applied in the direction of thermoelectric device junction lead-out materials, thermoelectric device manufacturing/processing, etc., can solve the problems of low conductivity, low ZT value, limited application, etc., and achieve high ZT and power factor High, easy industrial production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing an Al-doped Cu-deficient BiCuSeO-based thermoelectric material, comprising the steps of:

[0035] (1) Using Bi, Cu, Bi 2 o 3 , Se, Al, Al 2 o 3Powder as raw material, according to Bi:Cu:Bi 2 o 3 :Se:Al:Al 2 o 3 =(1-x) / 3:1-x:(1-x) / 3:1:x / 3:x / 3 The ratio batching of substance amount, x=0.025; Each component is mixed homogeneously, gets mixed powder;

[0036] (2) Pour the mixed powder into the ball mill, according to the ball-to-material ratio of 10:1, ball mill at a speed of 500r / min under the protection of argon for 5h, and the powder obtained by ball milling is then ground for 45min with an agate mortar, and then placed in vacuum drying Dry in the box, and dry at a temperature of 70°C for 8 hours to obtain a dry powder;

[0037] (3) Seal the dry powder into a vacuum quartz tube, then place it in a muffle furnace for high-temperature solid-state reaction, heat it to 350°C at a heating rate of 5°C / min, keep it warm for 8 hours, and then rais...

Embodiment 2

[0042] A method for preparing an Al-doped Cu-deficient BiCuSeO-based thermoelectric material, comprising the steps of:

[0043] (1) Using Bi, Cu, Bi 2 o 3 , Se, Al, Al 2 o 3 Powder as raw material, according to Bi:Cu:Bi 2 o 3 :Se:Al:Al 2 o 3 =(1-x) / 3:1-x:(1-x) / 3:1:x / 3:x / 3 The ratio batching of substance amount, x=0.05; Each component is mixed uniformly, obtains mixed powder;

[0044] (2) Pour the mixed powder into a ball mill, according to the ball-to-material ratio of 15:1, ball mill for 6 hours at a speed of 300r / min under the protection of argon, and then grind the powder obtained by ball milling with an agate mortar for 60 minutes, and then place it in vacuum drying Dry in the box, and dry at a temperature of 60°C for 10 hours to obtain a dry powder;

[0045] (3) Seal the dry powder into a vacuum quartz tube, then place it in a muffle furnace for high-temperature solid-state reaction, heat it to 300°C at a heating rate of 5°C / min, keep it warm for 10 hours, and th...

Embodiment 3

[0050] A method for preparing an Al-doped Cu-deficient BiCuSeO-based thermoelectric material, comprising the steps of:

[0051] (1) Using Bi, Cu, Bi 2 o 3 , Se, Al, Al 2 o 3 Powder as raw material, according to Bi:Cu:Bi 2 o 3 :Se:Al:Al 2 o 3 =(1-x) / 3:1-x:(1-x) / 3:1:x / 3:x / 3 The ratio batching of substance amount, x=0.075; Each component is mixed homogeneously, gets mixed powder;

[0052] (2) Pour the mixed powder into a ball mill, according to the ball-to-material ratio of 20:1, ball mill for 5 hours at a rotational speed of 500r / min under the protection of argon, and then grind the powder obtained by ball milling with an agate mortar for 30 minutes, and then place it in vacuum drying Dry in the box, and dry at a temperature of 50°C for 12 hours to obtain a dry powder;

[0053] (3) Seal the dry powder into a vacuum quartz tube, then place it in a muffle furnace for high-temperature solid-state reaction, heat it to 350°C at a heating rate of 5°C / min, keep it warm for 8 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com