Preparation method of bismuth sulfide polycrystal thermoelectric material

A thermoelectric material and bismuth sulfide technology, which is applied in the field of preparation of bismuth sulfide polycrystalline thermoelectric materials, can solve the problems of low electrical conductivity and low ZT value of materials, achieve simple equipment, inhibit grain growth and fusion, and improve electrical transmission performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited to the content described.

[0018] A preparation method of bismuth sulfide polycrystalline thermoelectric material, specifically comprising the following steps:

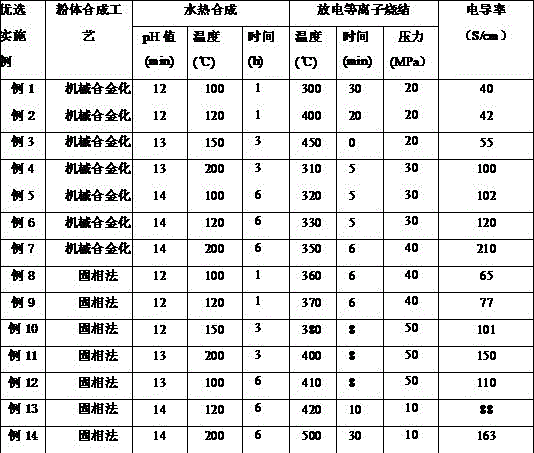

[0019] (1) Prepare bismuth sulfide powder with an average particle size of 5-500nm. In the embodiment of the present invention, bismuth sulfide powder is prepared by mechanical alloying method or bismuth sulfide block synthesized by solid phase method, and the bismuth sulfide block is ground and sieving to obtain bismuth sulfide powder.

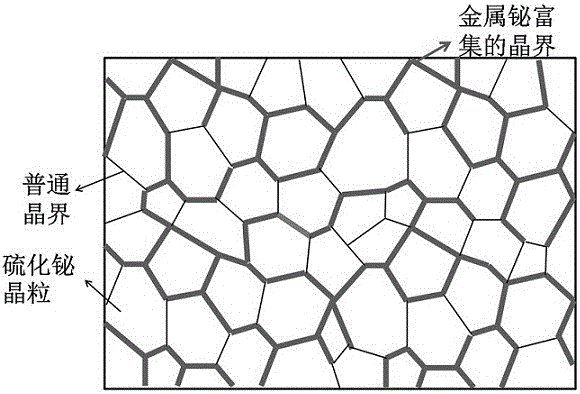

[0020] (2) Using the bismuth sulfide powder prepared in step (1) as the precursor powder, the bismuth sulfide / bismuth core-shell powder was prepared by hydrothermal method: ethylene glycol was used as solvent, hydrazine hydrate was used as reducing agent, NaOH and The mixed bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com