Food-grade titanium dioxide producing system and technology

A titanium dioxide and production system technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems that the safety of food-grade titanium dioxide cannot be guaranteed, affect product purity and quality, and have toxic residues, etc., to achieve safety assurance, The effect of improving purity and yield and avoiding residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

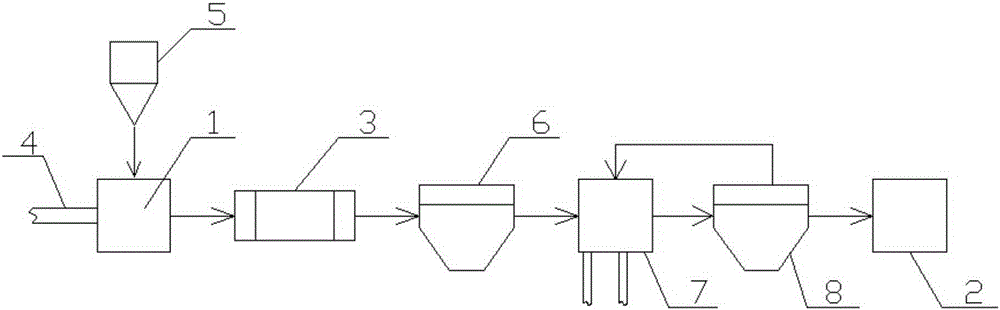

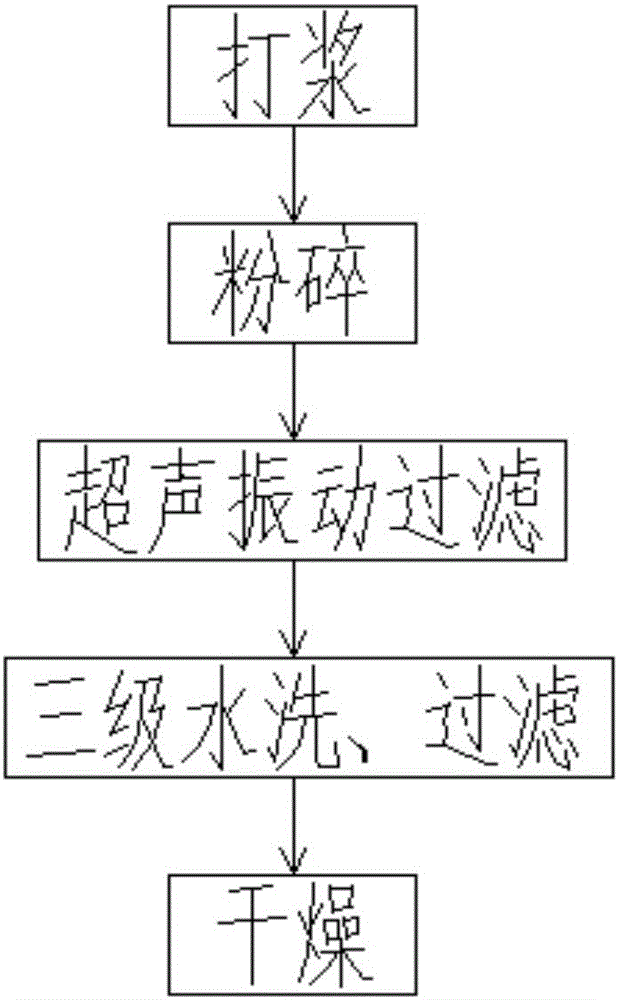

[0026] Example 1, such as figure 1 As shown, a washing mechanism is connected between the first ultrasonic vibrating screen 6 and the drying device 2. The washing mechanism includes a connected washing tank 7 and a filter device. The washing tank 7 is connected with a water pipeline and an acetic acid pipeline. 7. The input end is connected to the output end of the first ultrasonic vibrating screen 6, and the output end of the filtering device is connected to the input end of the drying device 2. The filtering device is the second ultrasonic vibrating screen 8. On this basis, food-grade titanium dioxide The production process includes the following steps:

[0027] a. Input the titanium dioxide raw material and deionized water into the beating tank 1, the mixing ratio between the titanium dioxide raw material and the deionized water is 3:7 by weight, and the stirring device forms a slurry after stirring and beating;

[0028] B, the slurry is injected into the crushing device 3...

Embodiment 2

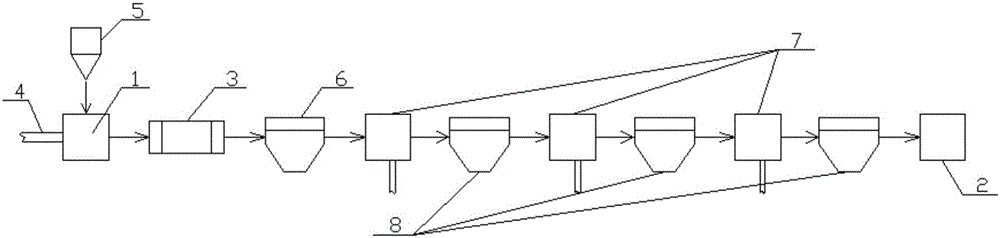

[0032] Example 2, such as figure 2 As shown, the first ultrasonic vibrating screen 6 and the drying device 2 are sequentially connected with three washing mechanisms, the washing mechanism includes a washing tank 7 and a filtering device connected from front to back, and the three washing tanks 7 are respectively connected with water pipes Road, acetic acid pipeline and water pipeline, the input end of the washing tank 7 of the most front washing mechanism is connected with the output end of the first ultrasonic vibrating screen 6, and the output end of the filter device of the last washing mechanism is connected with the input end of the drying device 2, said The filtering device is the second ultrasonic vibrating screen 8, on this basis, the production technology of food-grade titanium dioxide comprises the following steps:

[0033] a. Input the titanium dioxide raw material and deionized water into the beating tank 1, the mixing ratio between the titanium dioxide raw mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com