Desulphurization wastewater zero discharge system of coal-fired unit of thermal power plant

A technology for thermal power plants and coal-fired units, applied in general water supply conservation, gaseous discharge wastewater treatment, water/sewage multi-stage treatment, etc., can solve the problems of immature technology and high investment costs, and increase the load shock resistance The effect of energy saving, fast crystallization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

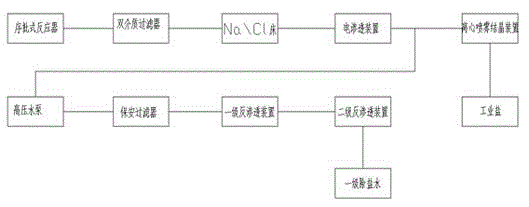

[0018] Such as figure 1 As shown in the flow chart, the present invention discloses a zero-discharge system for desulfurization wastewater of coal-fired units in thermal power plants. Sedimentation tank (buffer tank), filtrate tank, neutralization tank, reaction tank, flocculation tank, clarification tank, effluent tank, and the final wastewater reaches the standard for reuse. The desulfurization wastewater treated by this process will have high suspended solids and high salt content , the power plant cannot be reused. In order to realize the zero discharge of desulfurization waste water, the present invention comprises in turn:

[0019] Sequencing batch reactor: use single subtraction or double alkali method to adjust the pH value to 10-11, and remove metal ions and sulfate radicals in water; adopting sequencing batch reactor increases the load impact resistance of the system, During the clarification process, the tempering of the water is realized at the same time.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com