Preparation method of trimethoprim midbody 3,5-dibromo-4-hydroxy benzaldehyde

A technology of hydroxybenzaldehyde and trimethoprim, which is applied in the field of preparation of trimethoprim intermediate 3,5-dibromo-4-hydroxybenzaldehyde, can solve the cumbersome preparation process, strong bromine toxicity, and short reaction time Long and other problems, to achieve the effect of simple process, fast reaction speed and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

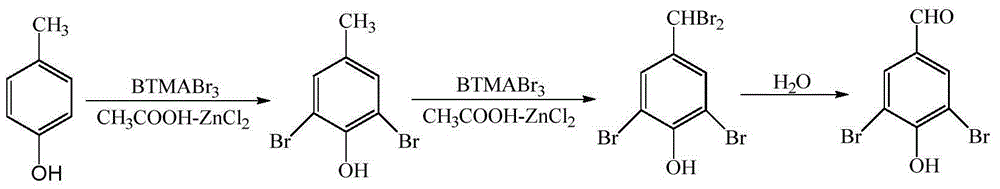

Method used

Image

Examples

Embodiment 1

[0021] Add 10.8g (0.1mol) of p-cresol, 48.6g of acetic acid, and 0.68g (0.005mol) of zinc chloride into the three-necked flask, stir, cool down to 0°C and slowly add BTMABr 3 156g (0.4mol), react at 10°C for 1 hour, then raise the temperature to 90°C for 1.5 hours.

[0022] After the reaction was completed, acetic acid was recovered by distillation under reduced pressure, the substrate was stirred with 70ml of water, heated and refluxed for 4 hours, cooled to room temperature, filtered, washed with water, and dried to obtain 26.40g of 3,5-dibromo-4-hydroxybenzaldehyde, HPLC purity It was 98.75%, and the yield was 93.11%.

Embodiment 2

[0024] Add 10.8g (0.1mol) of p-cresol, 54g of acetic acid, 0.68g (0.005mol) of zinc chloride into the three-necked flask, stir, cool down to 0°C and slowly add BTMABr 3 175.5g (0.45mol), reacted at 15°C for 2 hours, then raised the temperature to 95°C for 3 hours.

[0025] After the reaction was completed, acetic acid was recovered by distillation under reduced pressure, the substrate was stirred with 70ml of water, heated and refluxed for 2 hours, cooled to room temperature, filtered, washed with water, and dried to obtain 26.74g of 3,5-dibromo-4-hydroxybenzaldehyde, HPLC purity It is 98.09%, and the yield is 93.68%.

Embodiment 3

[0027] Add 10.8g (0.1mol) of p-cresol, 54g of acetic acid, 0.68g (0.005mol) of zinc chloride into the three-necked flask, stir, cool down to 0°C and slowly add BTMABr 3 159.9 g (0.41 mol), react at 12°C for 1.5 hours, then raise the temperature to 92°C for 2 hours.

[0028] After the reaction was completed, acetic acid was recovered by distillation under reduced pressure, the substrate was stirred with 70ml of water, heated and refluxed for 3 hours, cooled to room temperature, filtered, washed with water, and dried to obtain 26.49g of 3,5-dibromo-4-hydroxybenzaldehyde, HPLC purity It is 99.22%, and the yield is 93.86%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com