Flavones separated and purified from shepherd's purse, and preparation method and application thereof

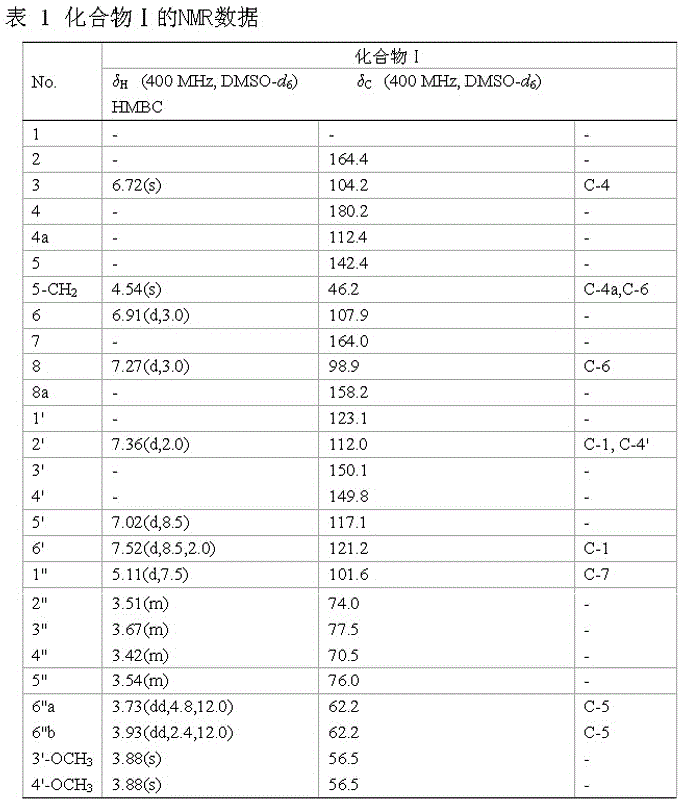

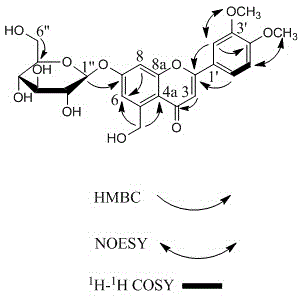

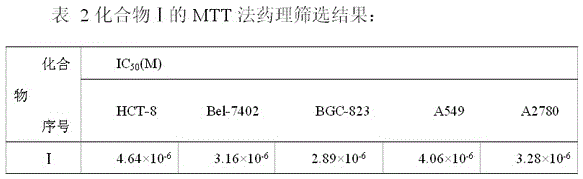

A flavonoid compound, separation and purification technology, applied in the field of 5-hydroxymethyl neoflavonoid compound and preparation thereof, and achieves the effects of low preparation cost, novel structure and good development and utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of this flavonoid compound comprises the following steps:

[0027] (1) Take dried aerial part of shepherd's purse as raw material, after crushing, add ethanol solution with a mass concentration of 70% to it for ultrasonic extraction for 20-40min, filter after extraction, collect filtrate, and add Ethanol solution with a mass concentration of 70%, repeat the above-mentioned ultrasonic extraction and filtration operations twice, combine all filtrates, concentrate under reduced pressure until there is no solvent, and extract the extract for future use;

[0028] (2) Add distilled water to the extraction extract obtained in step (1), and obtain a dispersion liquid after ultrasonic dispersion, and then sequentially extract the dispersion liquid with petroleum ether, ethyl acetate and n-butanol, and extract each part of the obtained The liquid was concentrated under reduced pressure to obtain the petroleum ether part, the ethyl acetate part, the n-butano...

Embodiment 1

[0033] Get 11.0kg dried shepherd's purse aerial part as raw material, after pulverizer pulverizes, add mass concentration in raw material powder and be 70% ethanol solution and carry out ultrasonic extraction 3 times, half an hour each time, merge all filtrates after extraction finishes, reduce through low temperature Concentrate under pressure until there is no solvent to obtain 1100 g of extract extract, which is ultrasonically dispersed and suspended in distilled water. After that, the dispersion is extracted with petroleum ether, ethyl acetate and n-butanol successively, and each part of the obtained The extract was concentrated under reduced pressure to obtain 108.5g of petroleum ether, 237.0g of ethyl acetate, and 320.7g of n-butanol. Combining with the previous pharmacological screening results, the active part of shepherd's purse-ethyl acetate was separated in a targeted manner. Ultrasonically disperse the obtained ethyl acetate parts in water, and after filtering, pass...

Embodiment 2

[0035]Take 11.0kg of dried shepherd's purse aerial part as raw material, pulverize after pulverizer, add the ethanol solution that mass concentration is 70% to raw material powder and carry out ultrasonic extraction 3 times, each time 20min, after extraction finishes, combine all filtrates, through low temperature depressurization Concentrate until there is no solvent to obtain 1100 g of extract extract, which is ultrasonically dispersed and suspended in distilled water. After that, the dispersion is extracted with petroleum ether, ethyl acetate and n-butanol in sequence, and each part of the obtained extract is extracted The liquid was concentrated under reduced pressure to obtain 106.8g of petroleum ether, 246.2g of ethyl acetate, and 325.1g of n-butanol. Combining with the previous pharmacological screening results, the active part of shepherd's purse-ethyl acetate was separated, and the The obtained ethyl acetate part is ultrasonically dispersed in water, and after filtrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com