Physicochemical-crosslinking-reaction high-polymer self-adhesive water-resistant coiled material

A technology of self-adhesive waterproof membrane and cross-linking reaction, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, mineral oil hydrocarbon copolymer adhesives, etc., can solve the problem that the waterproof performance cannot meet the actual situation demand and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

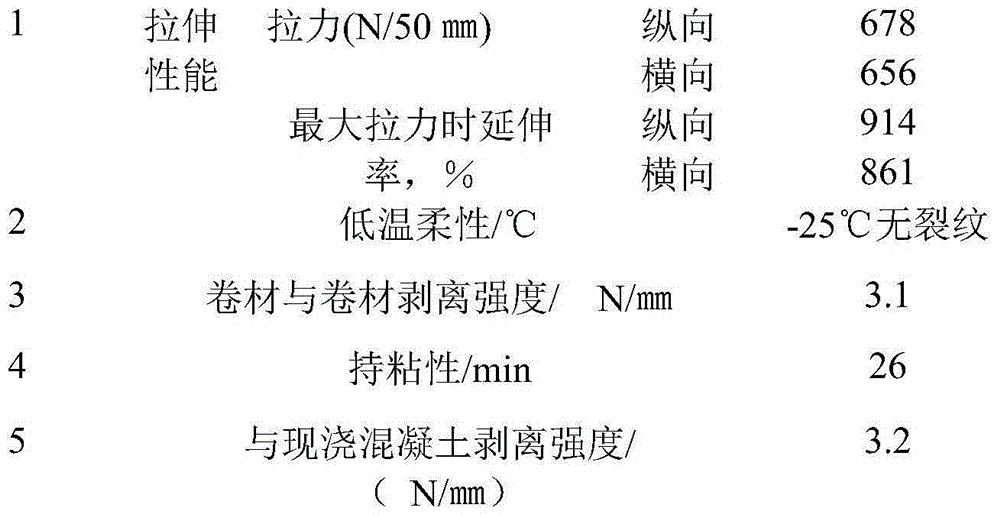

Embodiment 1

[0028] 1) The polymer adhesive layer, specifically, will: 40% of electron-rich system softening oil, 4% of hot melt adhesive grade elastomer, 7.5% of styrene-butadiene-styrene block copolymer, 2.5% of styrene butadiene rubber , 17% of waste rubber elastomer, 0.3% of anti-ultraviolet agent, 4% of high temperature resin, 12% of tackifying resin, 0.1% of interfacial agent, 3% of iron red, and 9.4% of talc are obtained after mixing.

[0029] 2) The polymer composite material sheet layer is composed of a composite layer of polyolefin and surface-modified nano-kaolin. Specifically, the nano-kaolin is surface-modified by a modifier to obtain surface-modified kaolin, and the surface-modified kaolin is combined with After mixing, the polyolefin is banned, granulated and dried, and then extruded by a single screw with three-roll calendering extrusion molding to obtain the material of the polymer composite sheet layer, the sheet thickness is 0.67-0.73mm.

[0030] 3) The polymer composite mate...

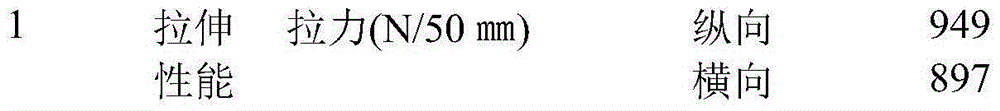

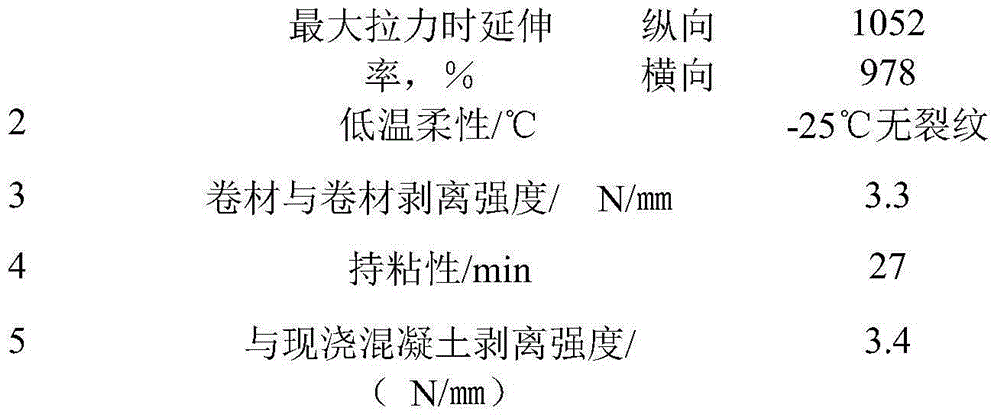

Embodiment 2

[0035] 1) The polymer adhesive layer, specifically: electron-rich system softening oil 42%, hot melt adhesive grade elastomer 5%, styrene-butadiene-styrene block copolymer 9%, styrene butadiene rubber 1% , 12% of waste rubber elastomer, 0.3% of anti-ultraviolet agent, 4% of high temperature resin, 13% of tackifying resin, 0.1% of interfacial agent, 4% of iron red, and 9.6% of talc are obtained after mixing.

[0036] 2) The polymer composite material sheet layer is composed of a composite layer of polyolefin and surface-modified nano-kaolin. Specifically, the nano-kaolin is surface-modified by a modifier to obtain surface-modified kaolin, and the surface-modified kaolin is combined with After mixing, the polyolefin is banned, granulated and dried, and then extruded by a single screw and three-roller calendering extrusion molding to obtain the material of the polymer composite sheet layer with a thickness of 1.16 to 1.24 mm.

[0037] 3) The polymer composite material sheet layer, the...

Embodiment 3

[0043] 1) The polymer adhesive layer, specifically, will: electron-rich system softening oil 48%, hot melt adhesive grade elastomer 6%, styrene butadiene rubber 5%, waste rubber elastomer 8%, UV protection agent 0.3%, tackifier It is obtained after mixing 17% resin, 0.1% interface agent, 4% iron red, and 11.6% talc.

[0044] 2) The polymer composite material sheet layer is composed of a composite layer of polyolefin and surface-modified nano-kaolin. Specifically, the nano-kaolin is surface-modified by a modifier to obtain surface-modified kaolin, and the surface-modified kaolin is combined with The polyolefin is mixed and then banned, granulated and dried, and then extruded by a single-screw three-roll calendering extrusion molding to obtain the material of the polymer composite sheet layer, and the sheet thickness is 1.45-1.55mm.

[0045] 3) The polymer composite material sheet layer, the polymer adhesive layer and the quartz sand layer are combined to obtain the physicochemical c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com