Formaldehyde-removing and odor-removing gel and preparation method thereof

A gel and formula technology, applied in the field of purification, can solve the problems of poor formaldehyde removal effect, short residence time, limited adsorption capacity, etc., and achieve the effect of improving the efficiency of aldehyde removal and deodorization, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

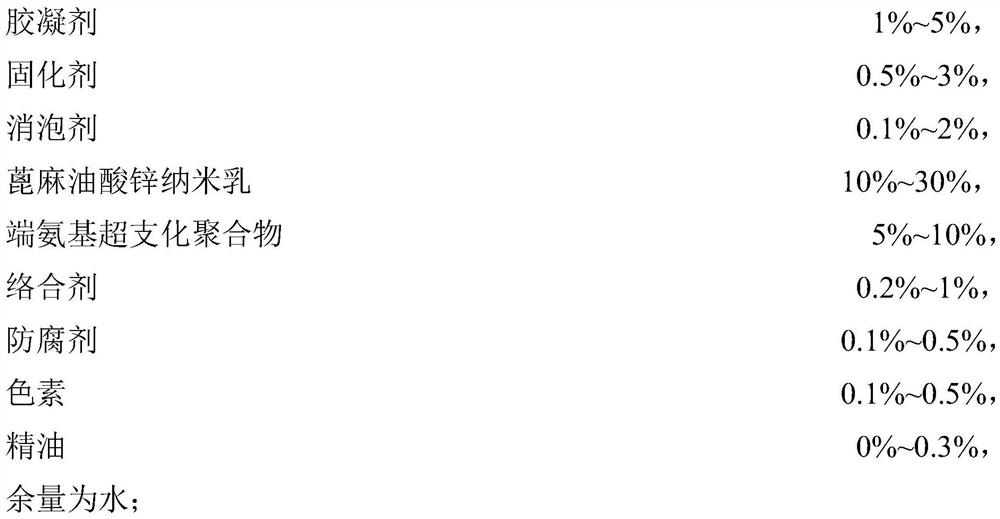

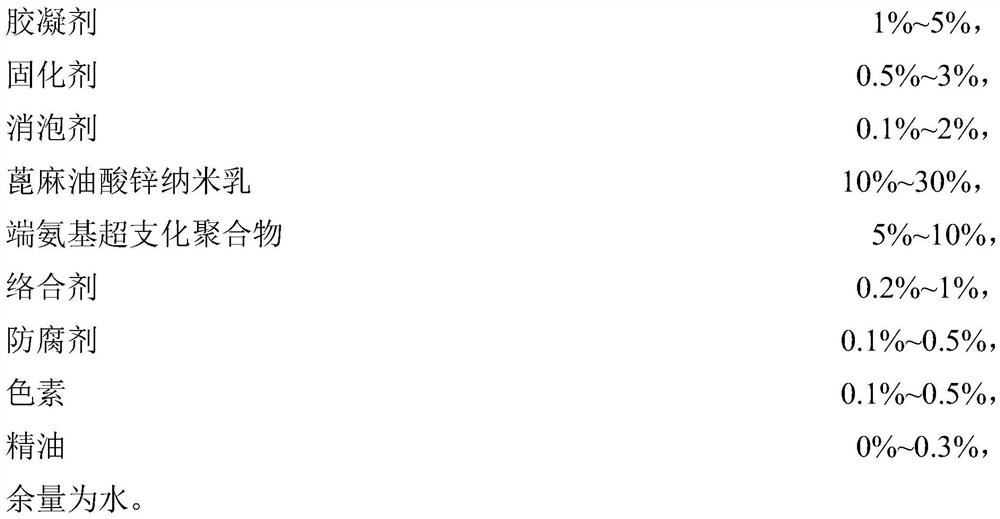

Method used

Image

Examples

Embodiment 1

[0044] (1) Add deionized water with a total water mass of 30% to the beaker at room temperature, and start the magnetic stirrer to stir;

[0045] (2) Slowly add 1 g of kappa-type carrageenan while stirring at a speed of 300 rpm, and continue stirring in the subsequent steps to maintain the speed, raise the temperature to 85° C., and stir until the carrageenan is completely dissolved to obtain solution A;

[0046] (3) Add 0.5 g of potassium chloride aqueous solution with a mass fraction of 10% dropwise into solution A, and continue stirring until completely dissolved to obtain solution B;

[0047] (4) Keep stirring, add 0.5g sodium edetate after the temperature of solution B drops to 40°C, then add 20g zinc ricinoleic acid nanoemulsion and 10g amino-terminated hyperbranched polymer, stir until completely dissolved to obtain a solution C;

[0048] Wherein, the preparation method of zinc ricinoleic acid nanoemulsion is as follows:

[0049] In the beaker, successively add 20g of...

Embodiment 2

[0056] (1) Add deionized water with a total water mass of 20% to the beaker at room temperature, and start the magnetic stirrer to stir;

[0057] (2) Slowly add 5 g of polyvinyl alcohol 2488 while stirring at a speed of 500 rpm, and continue stirring in the subsequent steps to maintain the speed, raise the temperature to 90° C., and stir until the polyvinyl alcohol 2488 is completely dissolved to obtain solution A;

[0058] (3) 3g of boric acid aqueous solution with a mass fraction of 5% was added dropwise to solution A, and continued to stir until completely dissolved to obtain solution B;

[0059] (4) Keep stirring, add 0.2g tetrasodium hydroxyethylidene diphosphate after the temperature of solution B drops to 50°C, then add 10g ricinoleic acid zinc nanoemulsion and 9g amino-terminated hyperbranched polymer, stir until completely dissolved, and obtain Solution C;

[0060] Wherein, the preparation method of zinc ricinoleic acid nanoemulsion is as follows:

[0061] In the be...

Embodiment 3

[0068] (1) Add deionized water with a total water mass of 25% to the beaker at room temperature, and start the magnetic stirrer to stir;

[0069] (2) Slowly add 3 g of chitosan while stirring at a speed of 400 rpm, and continue stirring in the subsequent steps to maintain the speed, raise the temperature to 80° C., and stir until the chitosan is completely dissolved to obtain solution A;

[0070] (3) Add 2 g of acetic acid aqueous solution with a mass fraction of 20% dropwise into solution A, and continue stirring until completely dissolved to obtain solution B;

[0071] (4) Continue to stir, add 1g of tetrasodium hydroxyethylidene diphosphate after the temperature of solution B drops to 60°C, then add 30g of zinc ricinoleic acid nanoemulsion and 5g of amino-terminated hyperbranched polymer, stir until completely dissolved, and obtain a solution C;

[0072] Wherein, the preparation method of zinc ricinoleic acid nanoemulsion is as follows:

[0073] In the beaker, successivel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com