Miniature fiber high temperature sensor based on Michelson interference theory and production method

A high-temperature sensor and optical fiber technology, which is applied to thermometers, instruments, thermometers, etc. that change physically/chemically, can solve the problems of measurement accuracy and repeatability affected by mechanical moving parts, and achieve great cost advantages, reliable performance, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

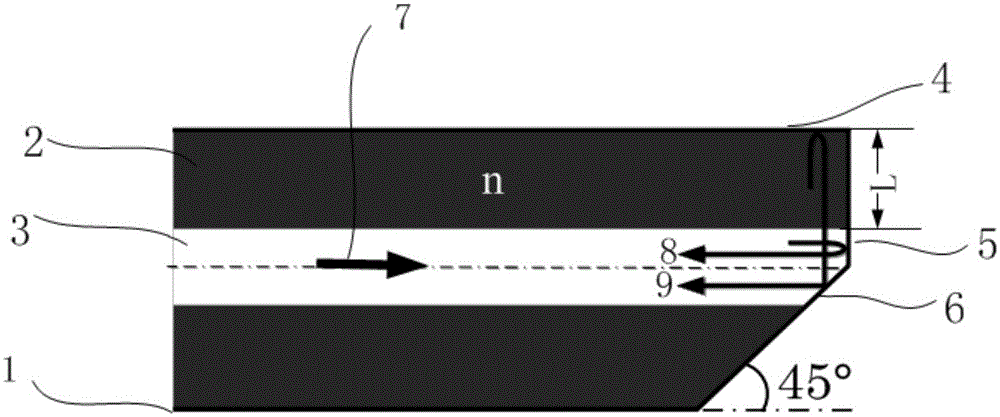

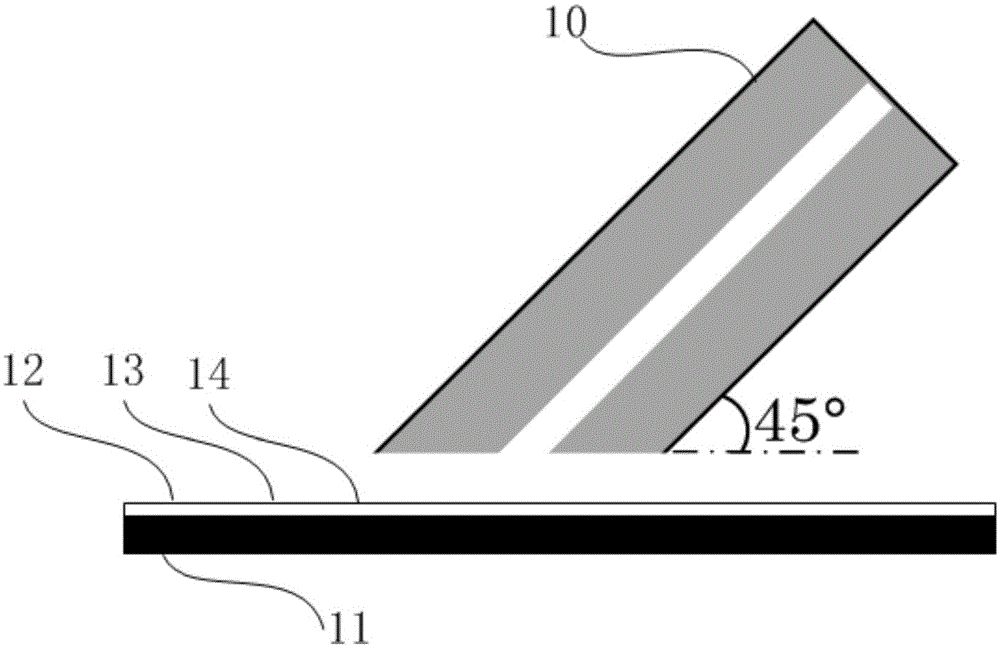

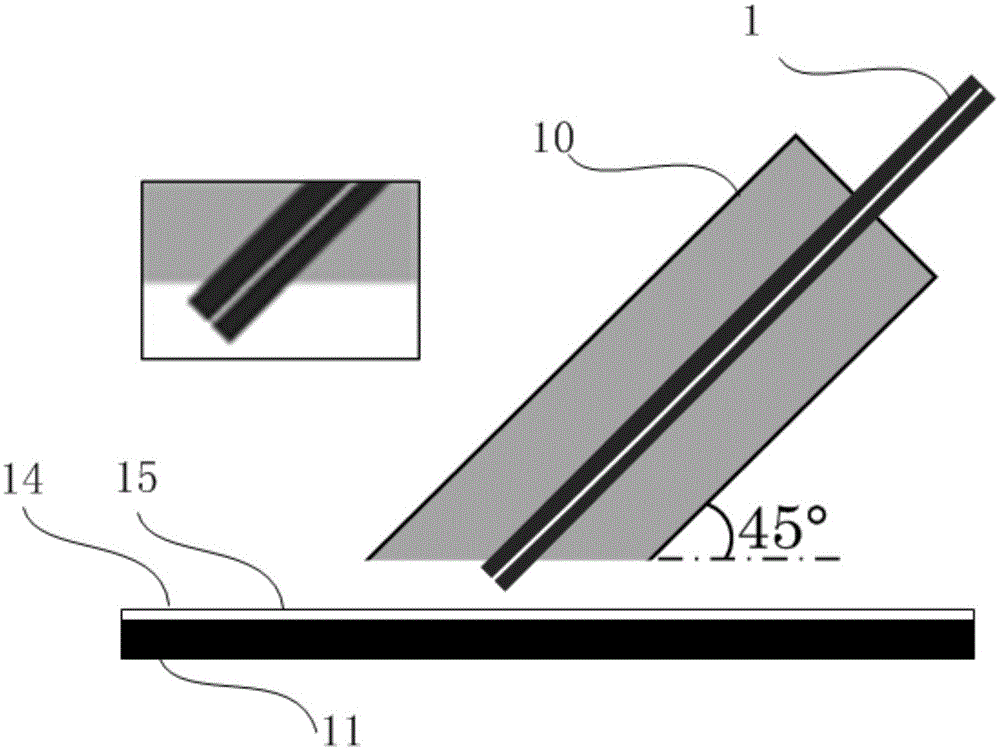

[0026] Embodiment 1: Based on the structure and manufacture of a miniature all-fiber Michelson temperature sensor.

[0027] Such as figure 1 As shown, the sensor splits the fiber core 3 into two parts by grinding the end face of the optical fiber 1. The first part of the fiber core is ground flat to form a reflection surface 5, and the second part of the fiber core is ground to a 45° angle to form a reflection surface 6. The fiber wall reflects surface 4, thereby forming a miniature Michelson interferometer. The production process is: first as figure 2As shown, fix the fiber ferrule 10 to the card slot, adjust the grinding angle to 45°; first paste 9 μm optical fiber polishing paper 12 on the turntable 11, set the rotation speed of the turntable 11 to 150 rpm, and polish the fiber ferrule for 10 to 30 minutes; then Replace the 3 μm optical fiber grinding paper 13 and the 1 μm optical fiber grinding paper 14 and grind for 10 minutes each. The rotation speed of the turntable ...

Embodiment 2

[0028] Embodiment 2: Measuring principle based on miniature all-fiber Michelson temperature sensor

[0029] Such as figure 1 As shown, by grinding the end face of the optical fiber, the optical fiber core layer 3 is split into two parts, the first part of the core is ground flat to form a plane reflective surface 5, and the beam is vertically reflected to form a reference beam 8 with a light intensity of 1 1 The second part of the fiber core is ground into a 45 ° angle to form a 45 ° angle reflection surface 6, and the light beam is totally reflected on this reflection surface, and the reflected light is vertically incident on the outer wall of the optical fiber. Incident to the reflective surface 6, part of the light is fully reflected again and coupled back to the fiber core 3 to form a sensing beam 9 with a light intensity of 1 2 When the reference beam 8 and the sensing beam 9 meet, two-beam interference will occur, and the interference light intensity can be expressed as...

example example 3

[0036] Example 3: Experimental system and demodulation based on miniature all-fiber Michelson temperature sensor

[0037] An experimental system based on a miniature all-fiber Michelson temperature sensor such as Figure 7 As shown, the light emitted by the broadband light source (SLD) 17 is incident on the miniature optical fiber Michelson sensor 20 through the circulator 18 , and the reflected light signal is incident on the spectrometer 19 through the circulator 18 again. Such as Figure 8 Shown is the Michelson interference fringes 22 received by the spectrometer. The sensor 20 is placed in the high temperature furnace 21, and the high temperature furnace 21 is used to provide temperature changes, starting from a normal temperature of 25°C, the temperature gradually increases to 950°C, and the temperature gradient is about 50°C. Figure 9 It shows that the peak value of the interference spectrum of the sensor drifts uniformly as the temperature changes from room temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Thermo-optic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com