Infrared blocking filter, solid-state imaging device, imaging device, and display device

A technology for shielding filters and infrared rays, applied in the direction of electric solid devices, electrical components, optical components, etc., can solve the problems of reduced product yield, increased number of resulting processes, and increased number of layers, etc., to achieve the effect of high transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

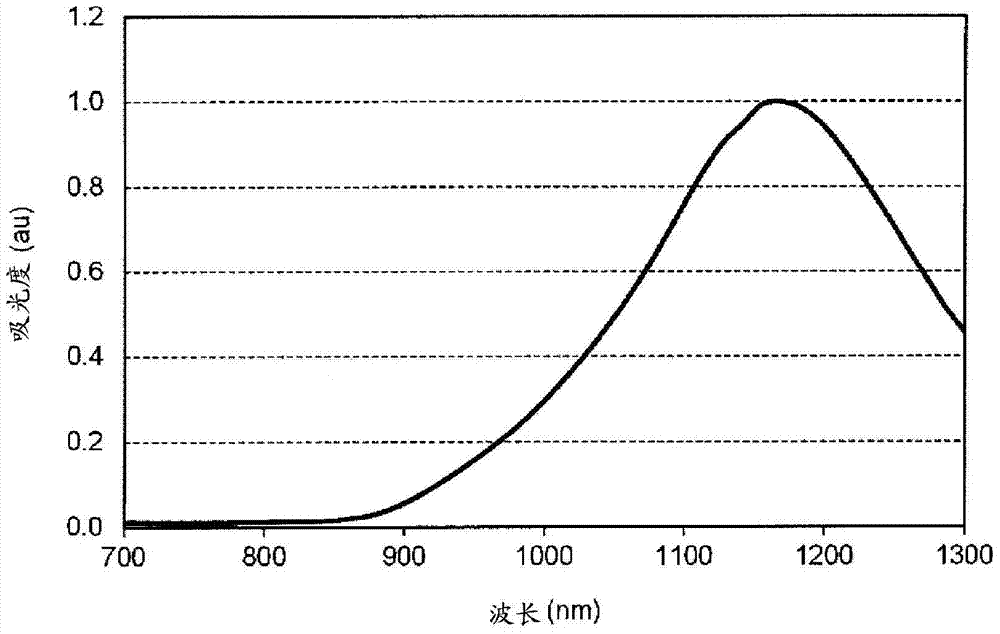

[0198] In a 15% by mass cyclohexanone solution of polyester resin (trade name B-OKP2 manufactured by Osaka Gas Chemicals Co., Ltd.), the dithiolane complex represented by the formula (F1-6) (dissolved in toluene and measured In the absorption spectrum of light in the wavelength region of 700-1300nm, λ max for 1168nm, the λ maxThe absorbance is 1, and the absorbance is 0.2, and the shortest wavelength is 891nm) Mixed at a ratio of 4.0 parts by mass of the disulfide complex to 100 parts by mass of the polyester resin, stirred well to dissolve, and prepared coating solution A .

[0199] In a 50% by mass tetrahydrofuran solution of an acrylic resin (trade name OGSOLEA-F5003 manufactured by Osaka Gas Chemicals Co., Ltd.), a squarylium dye (λmax=697 nm (toluene)) represented by the following formula was added in an amount of 100% by mass to the acrylic resin. 0.25 parts by mass of squarylium pigment was mixed, fully stirred to dissolve, and coating solution B was prepared.

[020...

Embodiment 2

[0206] Coating liquid A and coating liquid B were prepared similarly to Example 1.

[0207] The coating solution A was applied to one main surface of the glass substrate by a die coating method, and after drying at room temperature for 5 minutes under reduced pressure (about 670 Pa), it was heated at 90° C. for 30 minutes. After repeating the steps from coating to heating again, heating was performed at 150° C. for 15 minutes to form an infrared absorbing layer A having a thickness of 10.8 μm. As the glass substrate, a substrate made of soda glass (manufactured by SCHOTT, trade name D263) having a thickness of 1.0 mm was used.

[0208] Next, on the above-mentioned infrared absorbing layer A, silicon dioxide (SiO 2 ; Refractive index 1.45 (wavelength 550nm)) layer and titanium dioxide (TiO 2 ; Refractive index 2.32 (wavelength 550nm)) layer, form the dielectric multilayer film A (42 layers) that is formed by the composition shown in Table 1.

[0209] Next, the coating liquid...

Embodiment 3

[0212] In the absorption spectrum measured using the disulfide compound (dissolved in toluene) shown in formula (F1-7), λ max for 1170nm, the λ max The absorbance is 1, and the absorbance is 0.2, and the shortest wavelength is 966 nm) instead of the disulfide compound shown in the formula (F1-6), the coating solution A is prepared in the same manner as in Example 1. cloth liquid.

[0213] This coating solution was applied to one main surface of a glass substrate by a die coating method, dried at room temperature for 5 minutes under reduced pressure (about 670 Pa), and then heated at 90° C. for 30 minutes. After repeating the steps from this application to heating again, it was heated at 150° C. for 15 minutes to form an infrared absorbing layer with a thickness of 4.7 μm. As the glass substrate, a substrate made of CuO-containing fluorophosphate glass (manufactured by AGC Techno Glass Co., Ltd., trade name NF-50T) having a thickness of 0.35 mm was used.

[0214] Next, silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| full width at half maximum | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com