Sponge coated by metal organic skeleton material coated graphene and preparation method thereof

A technology for metal organic materials and sponge products, applied in the field of nanomaterials, can solve the problems of uninvented hydrophobic and lipophilic adsorbents, unsustainable recycling, long time consumption, etc., and achieves the effects of fast preparation, large oil absorption and strong hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

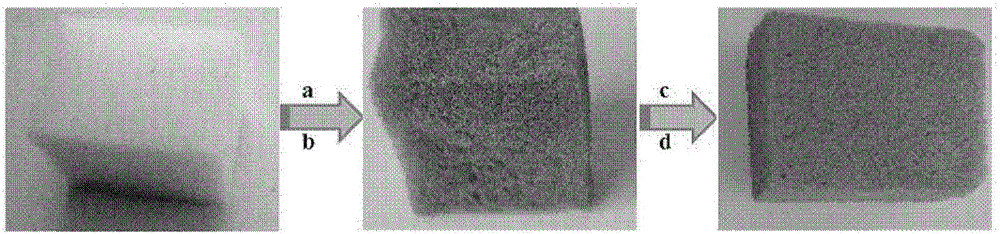

[0052] The preparation method of the metal-organic framework material-wrapped graphene-wrapped sponge in this embodiment is carried out as follows:

[0053] a. After washing and drying the sponge, soak it in the graphene oxide solution and absorb it to saturation.

[0054] b, the soaked sponge is centrifuged and dried to obtain graphene oxide / sponge;

[0055] c. Put the graphene oxide / sponge into the mother liquor of the metal-organic framework material to grow,

[0056] d. Take out the grown sponge and dry it to obtain metal organic framework material / graphene / sponge.

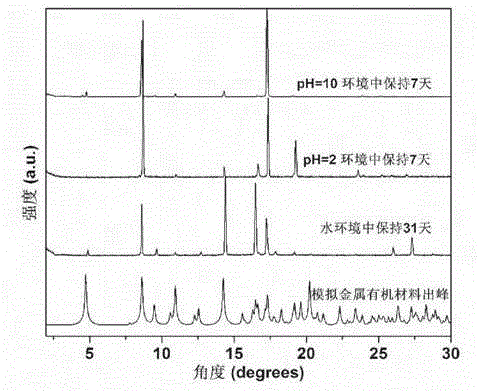

[0057] The metal-organic framework materials obtained in this example were soaked in different solutions, and powder X-ray diffraction was performed after a period of time. For the results, see figure 1 ,Depend on figure 1 It can be seen that the metal-organic framework material obtained in this example is stable in an aqueous solution, and is equally stable in an acidic solution with a pH of 2 and an alkal...

Embodiment 2

[0065] The preparation method of the metal-organic framework material-wrapped graphene-wrapped sponge in this embodiment is carried out as follows:

[0066] a. After washing and drying the sponge (2cm*2cm*2cm), soak it in the graphene oxide solution and absorb it to saturation.

[0067] b, the soaked sponge is centrifuged and dried to obtain graphene oxide / sponge;

[0068] c. Put the graphene oxide / sponge into the mother liquor of the metal-organic framework material to grow,

[0069] d. Take out the grown sponge and dry it to obtain metal organic framework material / graphene / sponge.

[0070] Put the graphene-wrapped sponge obtained in this example and the metal-organic framework material-wrapped graphene-wrapped sponge into the neck of the separatory funnel respectively, and then pour oil with a density greater than water from the top of the funnel. For the results, see Figure 7 . Depend on Figure 7 It can be seen that the ordinary graphene oxide-wrapped sponge is hydrop...

Embodiment 3

[0073] The preparation method of the metal-organic framework material-wrapped graphene-wrapped sponge in this embodiment is carried out as follows:

[0074] a. After washing and drying the sponge (2cm*2cm*2cm), soak it in the graphene oxide solution and absorb it to saturation.

[0075] b, the soaked sponge is centrifuged and dried to obtain graphene oxide / sponge;

[0076] c. Put the graphene oxide / sponge into the mother liquor of the metal-organic framework material to grow,

[0077] d. Take out the grown sponge and dry it to obtain metal organic framework material / graphene / sponge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water droplet contact angle | aaaaa | aaaaa |

| Water droplet contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com