Preparation and photocatalytic degradation method of TiO2/SiO2 composite oxide

A composite oxide and photocatalytic technology, applied in the field of chemical experiments, can solve problems such as lack of drinking water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

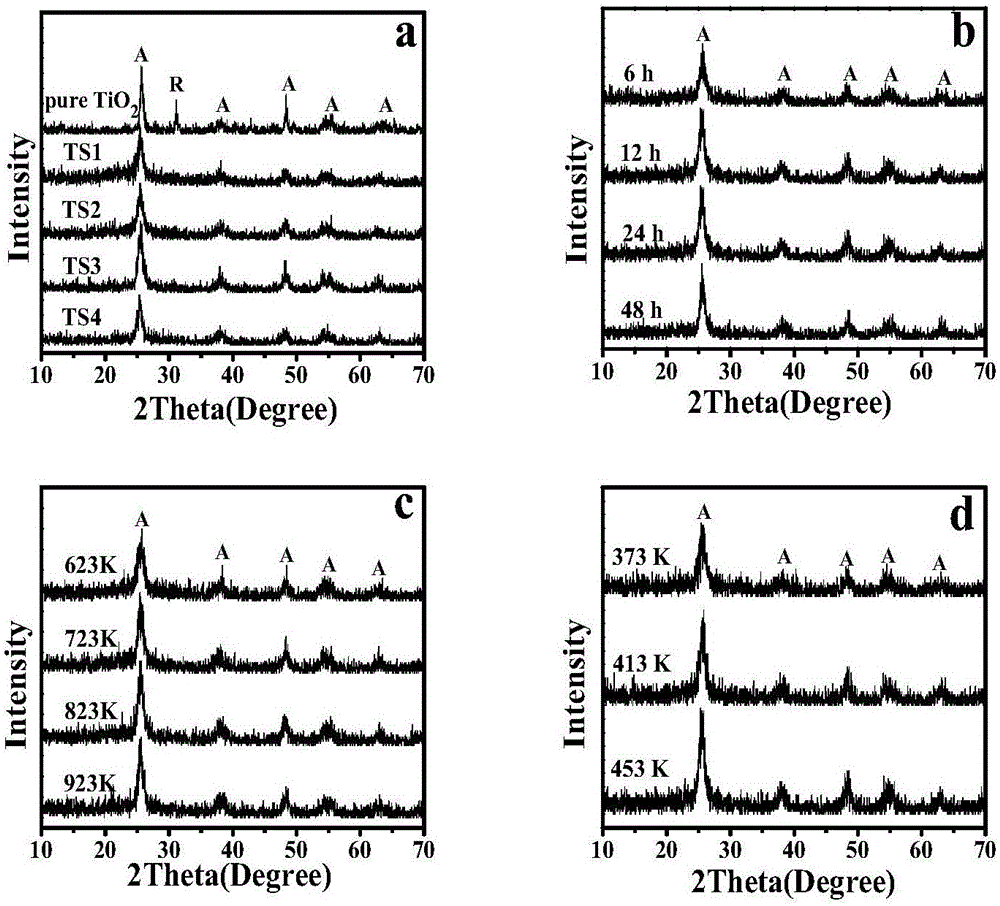

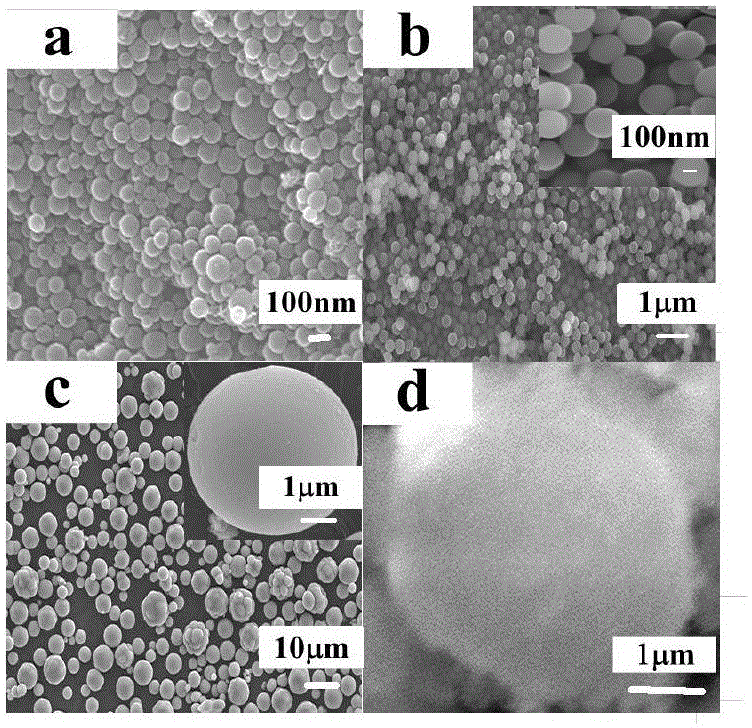

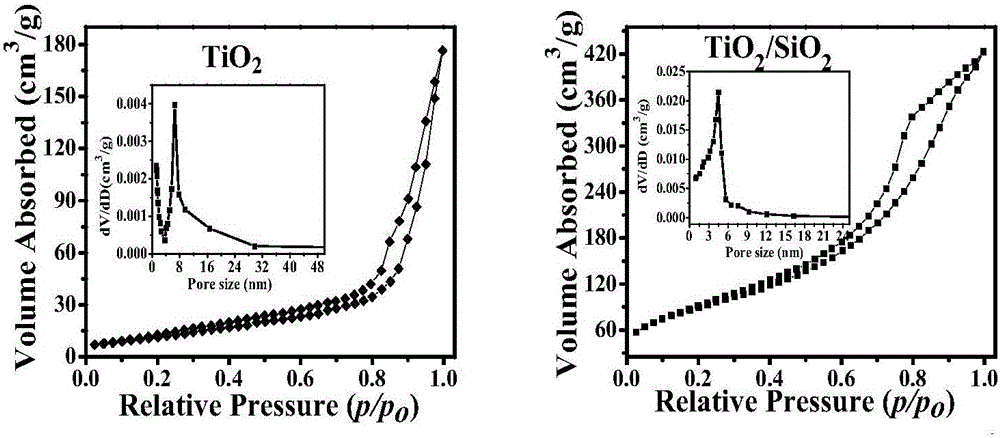

[0037] The present invention will be further described below in conjunction with accompanying drawing:

[0038] Reagents: tetra-n-butyl titanate (TBOT), tetraethyl orthosilicate (TEOS), urea, glacial HAc, PEG2000, glucose, terephthalic acid, rhodamine B, methyl orange, methylene blue, malachite green, twice distilled water;

[0039] Photocatalyst TiO 2 / SiO 2 Preparation of:

[0040] Preparation of C balls: 8gC 6 h 12 o 6 Soluble in 80mLH 2 O, transferred to a 100mL reactor, heated at 180°C for 6h, cooled naturally, washed with water and ethanol, centrifuged, and vacuum-dried at 80°C for 12h.

[0041] Add 10 mL of ethanol to 0.1 g of C balls and stir evenly, then add 4 mL of HCl (3M) dropwise and stir for 30 min, then add 1.1 mL of LTEOS dropwise and stir at room temperature for 24 h. Add 2.3mL HCl dropwise to 1.7mLTBOT, add 2.4mL ice HAc and stir for 30min, add 15mL ethanol and continue stirring, then add 0.6gPEG, 0.6gCO(NH 2 ) 2 Stir for 1h. The TBOT mixture was a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum absorption wavelength | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com