Preparation method of octagonal Mn3O4 nano particles

A nanoparticle and octahedron technology, which is applied in the field of synthesis of nanomaterials for chemical power sources, can solve the problems of few reports on air electrode catalysts for aluminum-air batteries, and achieve excellent oxygen reduction catalytic performance, simple process, and simple raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

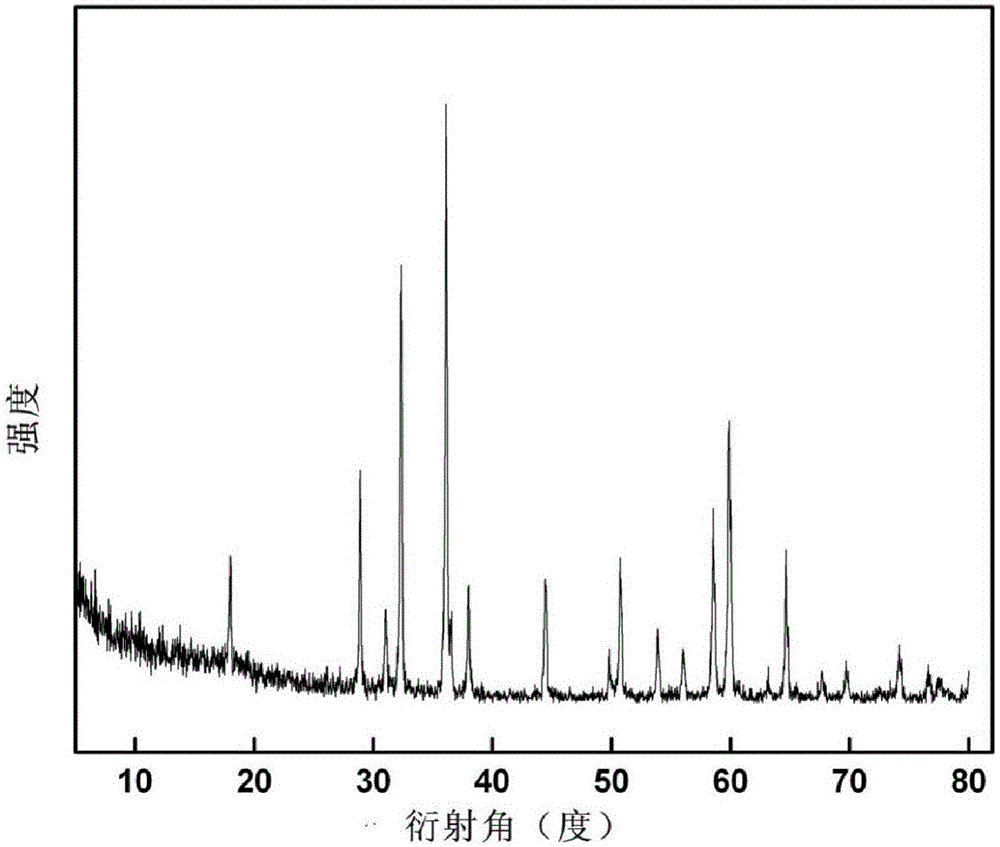

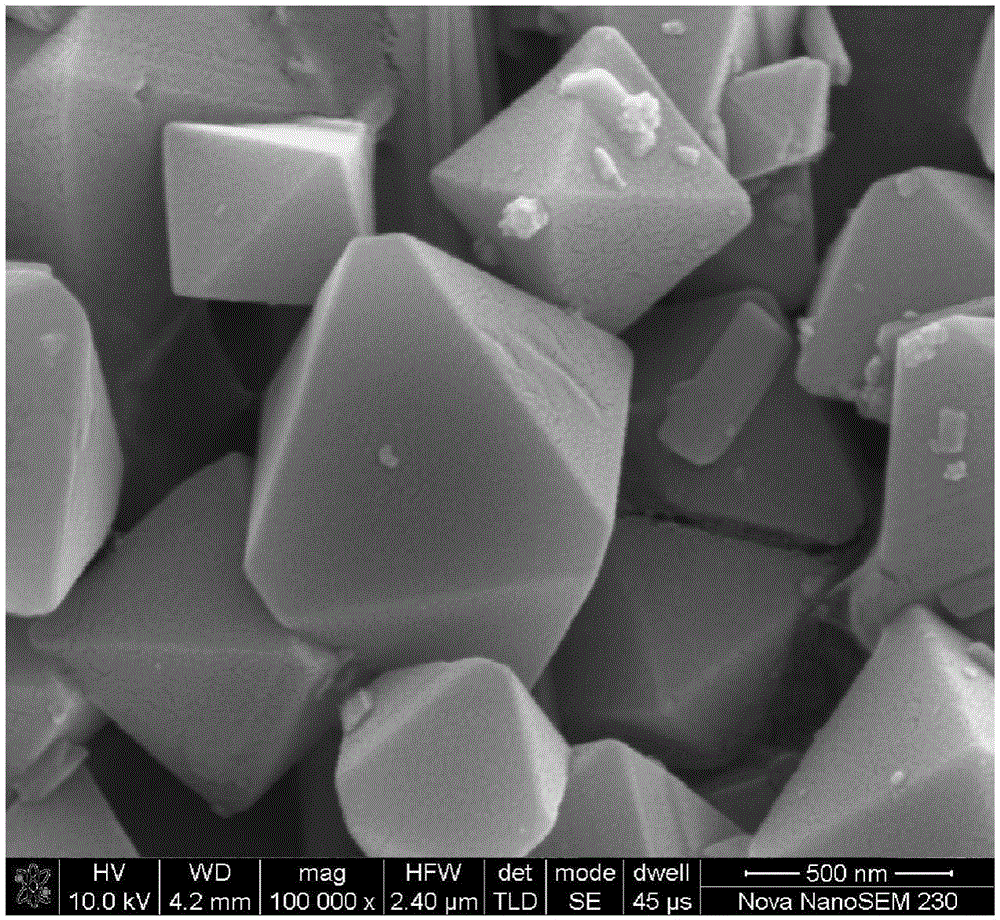

[0042] Weigh 0.4 g of potassium permanganate for use, accurately measure 20 ml of N-N-dimethylformamide (DMF) and 50 ml of deionized water, mix the two evenly, and then add potassium permanganate. After stirring evenly, it was transferred to a high pressure reaction kettle with a volume of 100ml and lined with polytetrafluoroethylene, placed in a blast drying oven, the reaction temperature was set to 140°C, and the reaction time was 12 hours, and the reaction was completed. Afterwards, the reaction kettle was taken out, cooled to room temperature naturally, filtered under reduced pressure, washed, dried under vacuum at 60°C for 24 hours, and finally ground to obtain the product. The obtained product was characterized by XRD, and its XRD pattern is shown in figure 1 , indicating that the product prepared by this example is pure phase Mn 3 O 4 . Scanning electron microscope observation of the product ( figure 2 ) shows that the obtained product is a regular octahedron with ...

Embodiment 2

[0045] Weigh 0.4 g of potassium permanganate for use, accurately measure 35 ml of N-N-dimethylformamide (DMF) and 35 ml of deionized water, mix the two evenly, and then add potassium permanganate. After stirring evenly, it was transferred to a high pressure reaction kettle with a volume of 100ml and lined with polytetrafluoroethylene, placed in a blast drying oven, the reaction temperature was set to 140°C, and the reaction time was 12 hours, and the reaction was completed. Afterwards, the reaction kettle was taken out, cooled to room temperature naturally, filtered under reduced pressure, washed, dried under vacuum at 60°C for 24 hours, and finally ground to obtain the product. The obtained product is characterized by XRD, and the result shows that the product prepared by this embodiment is pure phase Mn 3 O 4 . Scanning electron microscope observation of the product shows that the obtained product is a regular octahedron with a particle size of 400-500 nm.

Embodiment 3

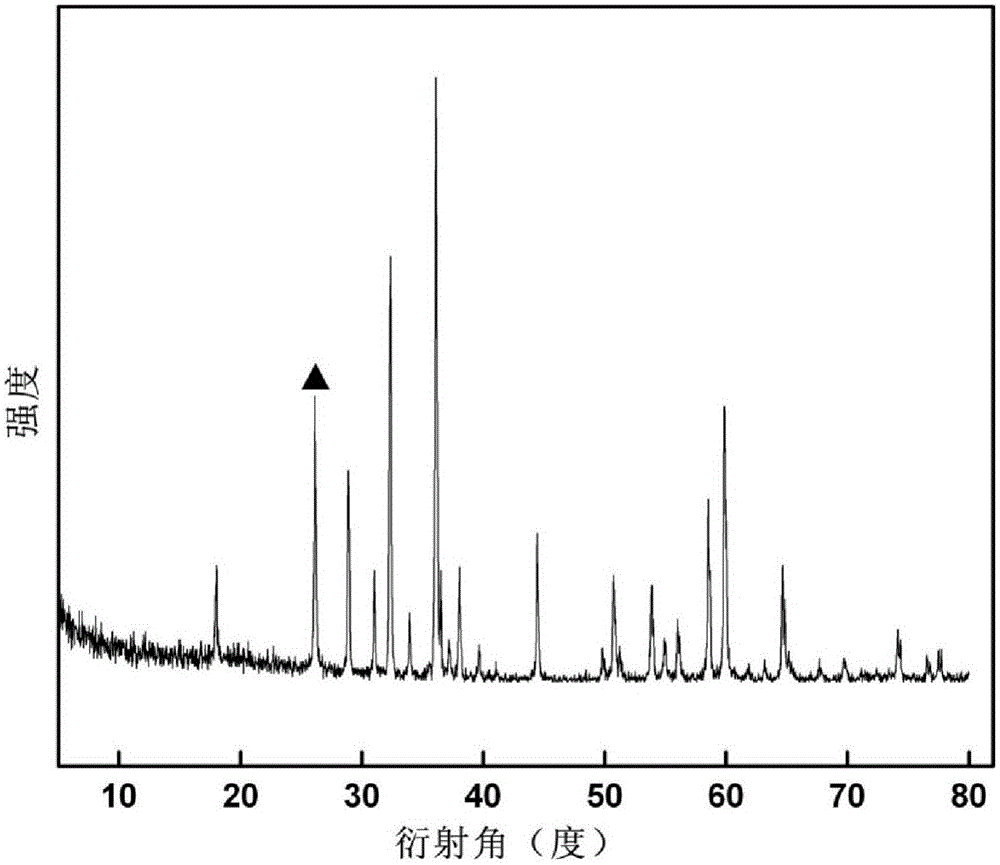

[0047] Weigh 0.4 g of potassium permanganate for use, accurately measure 20 ml of N-N-dimethylformamide (DMF) and 50 ml of deionized water, mix the two evenly, and then add potassium permanganate. After stirring evenly, it was transferred to a high-pressure reaction kettle with a volume of 100ml and lined with polytetrafluoroethylene, placed in a blast drying oven, set the reaction temperature to 120°C, and the reaction time to 12 hours, until the reaction was completed. Afterwards, the reaction kettle was taken out, cooled to room temperature naturally, filtered under reduced pressure, washed, dried under vacuum at 60°C for 24 hours, and finally ground to obtain the product. The obtained product is characterized by XRD, and its XRD pattern is shown in image 3 , the results show that the main phase of the product prepared by this embodiment is Mn 3 O 4 , the secondary phase is MnOOH. Scanning electron microscope observation of the product ( Figure 4 ) shows that the obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com