UV-cured POSS fluorine-containing acrylate segmented copolymer coating, preparation and application thereof

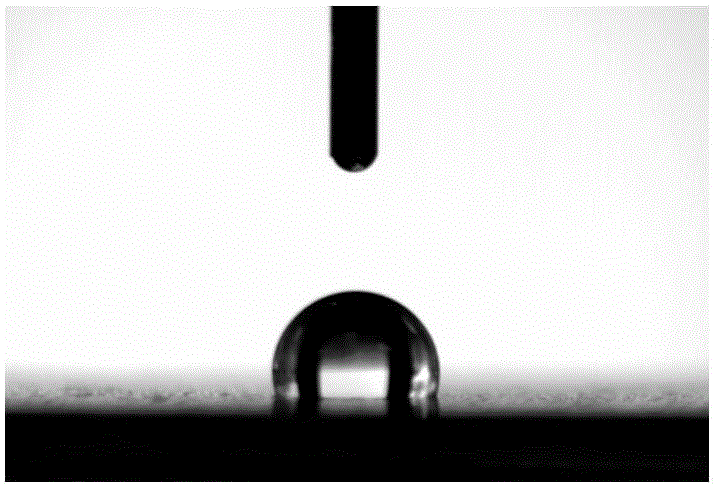

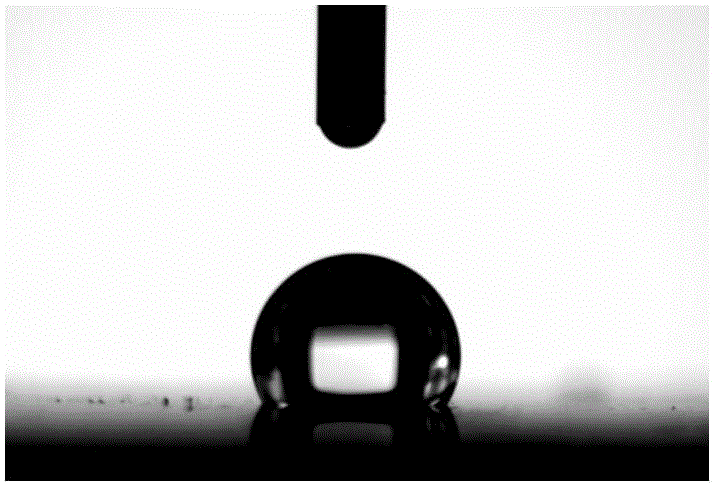

A technology of block copolymer and polyfluoroalkyl acrylate, which is applied in the direction of coating to achieve the effects of excellent coating performance, simple and efficient curing, and good hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

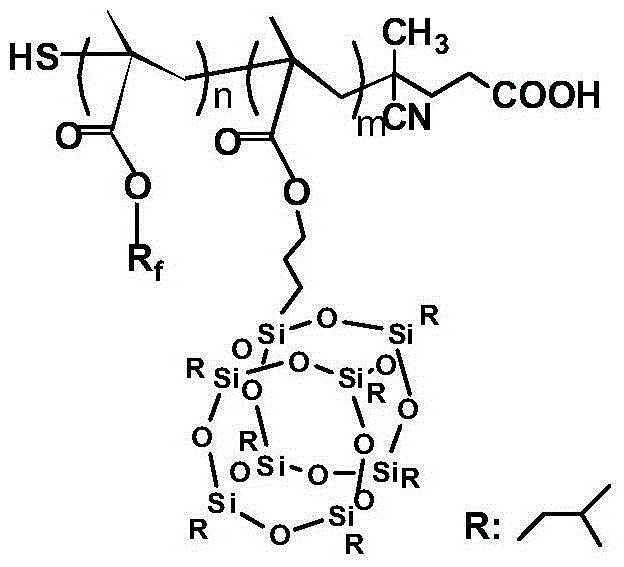

[0043] (1) Preparation of PMAPOSS-b-polydodecafluoroheptyl methacrylate block copolymer with mercapto group

[0044] Weigh 0.40g MAPOSS monomer, chain transfer agent 4-cyano-4-(thiobenzoyl) pentanoic acid (CPADB) 0.008g and initiator azobisisobutyronitrile (AIBN) 1.63mg, according to molar ratio 10 :2:1 is fully dissolved in toluene solvent, and prepared into a solution with a mass fraction of 20%, and then the air in the bottle is drained and protected with nitrogen. Under the condition of 70°C oil bath, the reaction was carried out under magnetic stirring for 10 hours; after the reaction, the product was dropped into a large amount of methanol for precipitation, unreacted monomers and solvents were removed, and vacuum-dried at room temperature for 24 hours to obtain PMAPOSS copolymer.

[0045] 0.80g of dodecafluoroheptyl methacrylate, 0.40g of PMAPOSS and 2.2mg of azobisisobutyronitrile (AIBN) were dissolved in trifluorotoluene according to the molar ratio of 40:2:1 to form ...

Embodiment 2

[0058] (1) Preparation of PMAPOSS-b-polydodecafluoroheptyl methacrylate block copolymer with mercapto group

[0059] Weigh 0.40g MAPOSS monomer, chain transfer agent 4-cyano-4-(thiobenzoyl)valeric acid (CPADB) 0.02g and initiator azobisisobutyronitrile (AIBN) 1.63mg, according to molar ratio 10 :5:1 is fully dissolved in toluene solvent, and prepared as a solution with a mass fraction of 30%, and then the air in the bottle is drained and protected with nitrogen. Under the condition of 60°C oil bath, magnetically stirred for 20 hours; after the reaction, the product was added dropwise to a large amount of methanol for precipitation, unreacted monomers and solvents were removed, and vacuum-dried at room temperature for 24 hours to obtain PMAPOSS copolymer.

[0060] 1.00g of dodecafluoroheptyl methacrylate, 0.80g of PMAPOSS and 2.20mg of azobisisobutyronitrile (AIBN) were dissolved in trifluorotoluene according to the molar ratio of 50:4:1, and configured into a solution with a m...

Embodiment 3

[0073] (1) Preparation of PMAPOSS-b-polydodecafluoroheptyl methacrylate block copolymer with mercapto group

[0074] Weigh 0.80g MAPOSS monomer, chain transfer agent 4-cyano-4-(thiobenzoyl)valeric acid (CPADB) 0.04g and initiator azobisisobutyronitrile (AIBN) 1.63mg, according to molar ratio 20 :10:1 is fully dissolved in toluene solvent, and prepared into a solution with a mass fraction of 50%, and then the air in the bottle is drained and protected with nitrogen. Under the condition of 70°C oil bath, magnetically stirred for 20 hours; after the reaction, the product was added dropwise to a large amount of methanol for precipitation, unreacted monomers and solvents were removed, and vacuum-dried at room temperature for 24 hours to obtain PMAPOSS copolymer.

[0075] 2.00g of dodecafluoroheptyl methacrylate, 2.00g of PMAPOSS and 2.21mg of azobisisobutyronitrile (AIBN) were dissolved in trifluorotoluene according to a molar ratio of 100:10:1, and configured into a solution with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com