A kind of ultraviolet curing poss fluorine-containing acrylate block copolymer coating and its preparation and application

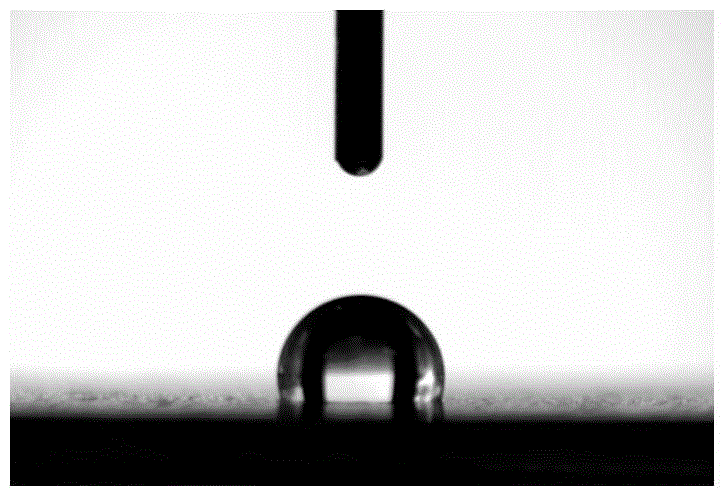

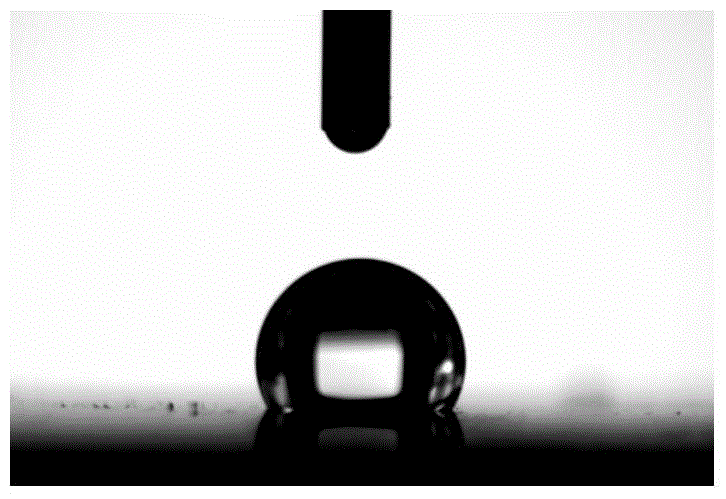

A technology of block copolymer and polyfluoroalkyl acrylate, which is applied in the direction of coating, etc., to achieve the effect of excellent coating film performance, simple and efficient curing, and good hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

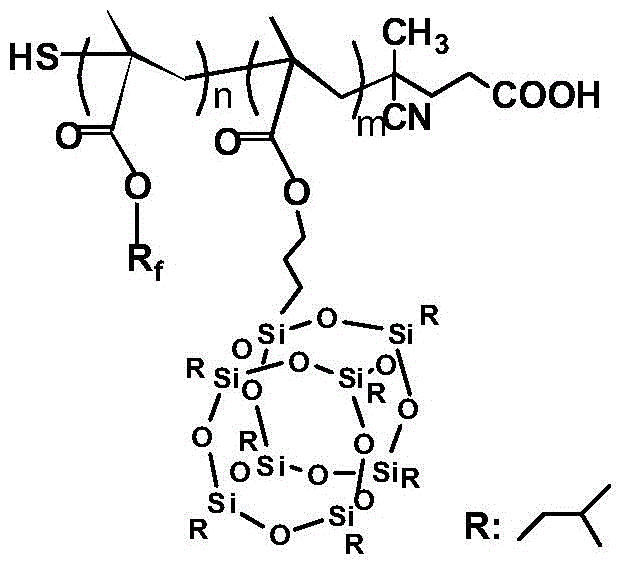

[0043] (1) Preparation of PMAPOSS-b-polydodecafluoroheptyl methacrylate block copolymer with mercapto group

[0044] Weigh 0.40g MAPOSS monomer, chain transfer agent 4-cyano-4-(thiobenzoyl)valeric acid (CPADB) 0.008g and initiator azobisisobutyronitrile (AIBN) 1.63mg, according to molar ratio 10:2:1 was fully dissolved in toluene solvent to prepare a solution with a mass fraction of 20%, and then the air in the bottle was drained and protected with nitrogen. Under the condition of 70°C oil bath, the reaction was carried out under magnetic stirring for 10 hours; after the reaction, the product was dropped into a large amount of methanol for precipitation, unreacted monomers and solvents were removed, and vacuum-dried at room temperature for 24 hours to obtain PMAPOSS copolymer.

[0045] Dissolve 0.80g of dodecafluoroheptyl methacrylate, 0.40g of PMAPOSS and 2.2mg of azobisisobutyronitrile (AIBN) in trifluorotoluene according to the molar ratio of 40:2:1 to form a solution with ...

Embodiment 2

[0058] (1) Preparation of PMAPOSS-b-polydodecafluoroheptyl methacrylate block copolymer with mercapto group

[0059] Weigh 0.40g MAPOSS monomer, chain transfer agent 4-cyano-4-(thiobenzoyl)valeric acid (CPADB) 0.02g and initiator azobisisobutyronitrile (AIBN) 1.63mg, according to molar ratio 10:5:1 was fully dissolved in toluene solvent, and prepared into a solution with a mass fraction of 30%, and then the air in the bottle was drained and protected with nitrogen. Under the condition of 60°C oil bath, magnetically stirred for 20 hours; after the reaction, the product was added dropwise to a large amount of methanol for precipitation, unreacted monomers and solvents were removed, and vacuum-dried at room temperature for 24 hours to obtain PMAPOSS copolymer.

[0060] Dissolve 1.00g of dodecafluoroheptyl methacrylate, 0.80g of PMAPOSS and 2.20mg of azobisisobutyronitrile (AIBN) in trifluorotoluene according to the molar ratio of 50:4:1, and configure a solution with a mass fract...

Embodiment 3

[0073] (1) Preparation of PMAPOSS-b-polydodecafluoroheptyl methacrylate block copolymer with mercapto group

[0074] Weigh 0.80g MAPOSS monomer, chain transfer agent 4-cyano-4-(thiobenzoyl)valeric acid (CPADB) 0.04g and initiator azobisisobutyronitrile (AIBN) 1.63mg, according to molar ratio 20:10:1 was fully dissolved in toluene solvent to prepare a solution with a mass fraction of 50%, and then the air in the bottle was drained and protected with nitrogen. Under the condition of 70°C oil bath, magnetically stirred for 20 hours; after the reaction, the product was added dropwise to a large amount of methanol for precipitation, unreacted monomers and solvents were removed, and vacuum-dried at room temperature for 24 hours to obtain PMAPOSS copolymer.

[0075] Dissolve 2.00g of dodecafluoroheptyl methacrylate, 2.00g of PMAPOSS and 2.21mg of azobisisobutyronitrile (AIBN) in trifluorotoluene according to the molar ratio of 100:10:1, and configure a solution with a mass fraction o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ice adhesion strength | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com