Method for rapidly extracting wax from sweet sorghum stem

A sweet sorghum and stalk technology, applied in the field of rapid wax extraction, can solve the problems of sweet sorghum wax extraction methods that have never been reported, and achieve the effect of low cost, simple steps and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for rapidly extracting wax from sweet sorghum stalks, comprising the following steps:

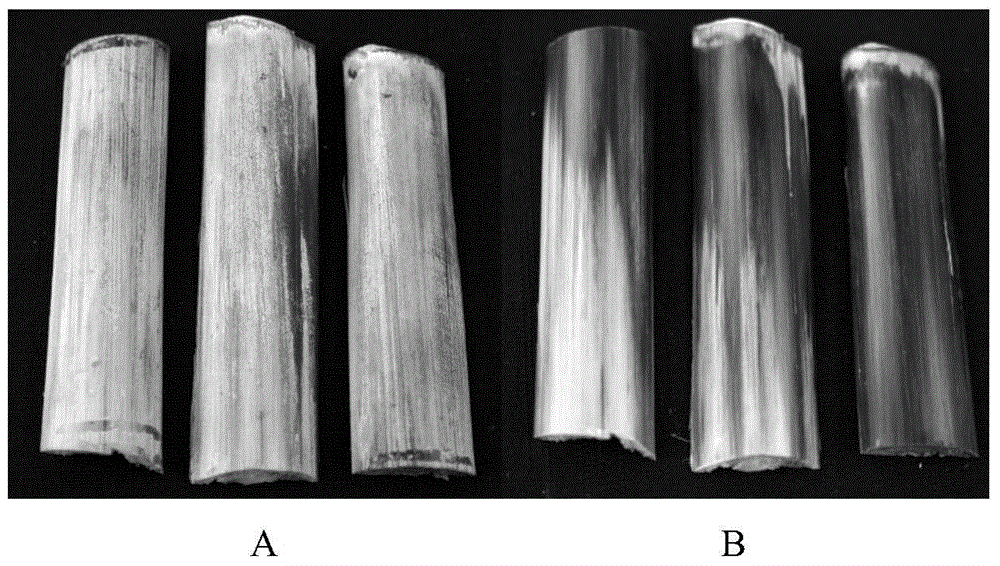

[0032] (1) Cut the stalk of the second stem node from the base of the sweet sorghum mature stage into a section with a length of 5 cm and a quality of 2 g, and place it in a petri dish;

[0033] (2) Add 30 mL of chloroform extract;

[0034] (3) placed in a full-temperature shaker, and the temperature was controlled at 60°C for 3 minutes;

[0035] (4) Take out the stalk and place it on an evaporating dish, place the extract in a fume hood and wait for the organic solvent to volatilize completely, that is, obtain the stalk wax to the greatest extent, and use the gas chromatography-mass spectrometer (GCMS) to obtain the white substance ) for component analysis, and the obtained component analysis results conform to the wax component characteristics.

Embodiment 2

[0037] (1) Cut the stalks of sweet sorghum mature stage into 3 cm long and 1 g segments, and place them in a petri dish;

[0038] (2) Add 30 mL of chloroform extract;

[0039] (3) placed in a full-temperature shaker, and the temperature was controlled at 50 ° C for 1 min;

[0040] (4) Take out the stalk and place it on an evaporating dish, and place the extract in a fume hood until the organic solvent is completely volatilized, that is, the waxy quality of the stalk can be obtained to the greatest extent.

Embodiment 3

[0042] (1) Cut the stalks of the second stem node from the base of sweet sorghum into small sections with a length of 7 cm and a quality of 3 g, and place them in a petri dish;

[0043] (2) Add 40 mL of chloroform extract;

[0044] (3) placed in a full-temperature shaker, and the temperature was controlled at 70°C for extraction for 3 minutes;

[0045] (4) Take out the stalk and place it on an evaporating dish, and place the extract in a fume hood until the organic solvent is completely volatilized, that is, the waxy quality of the stalk can be obtained to the greatest extent.

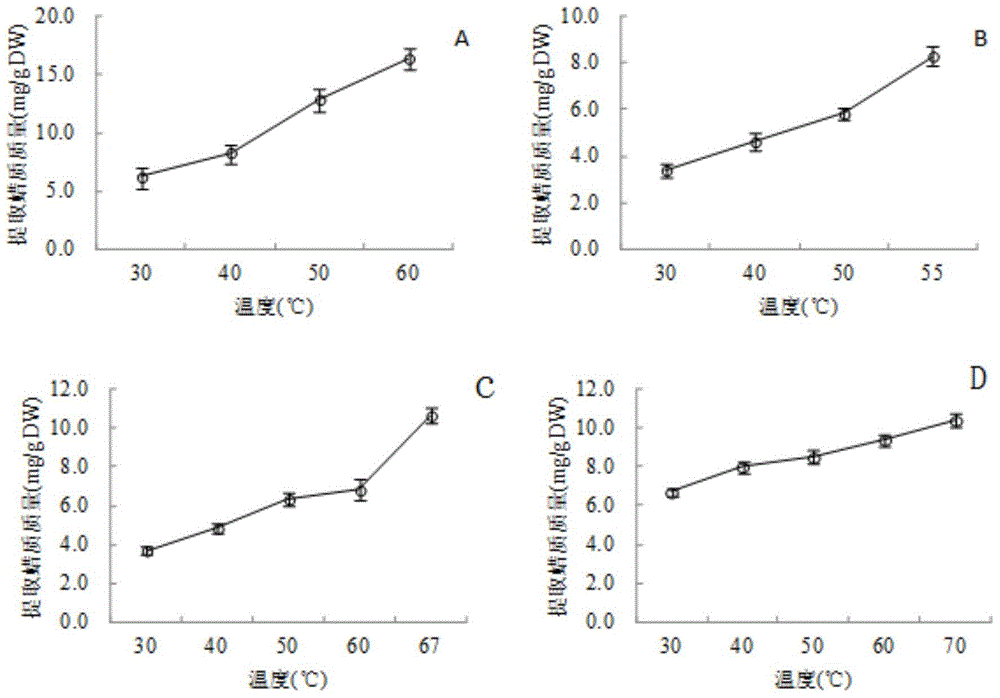

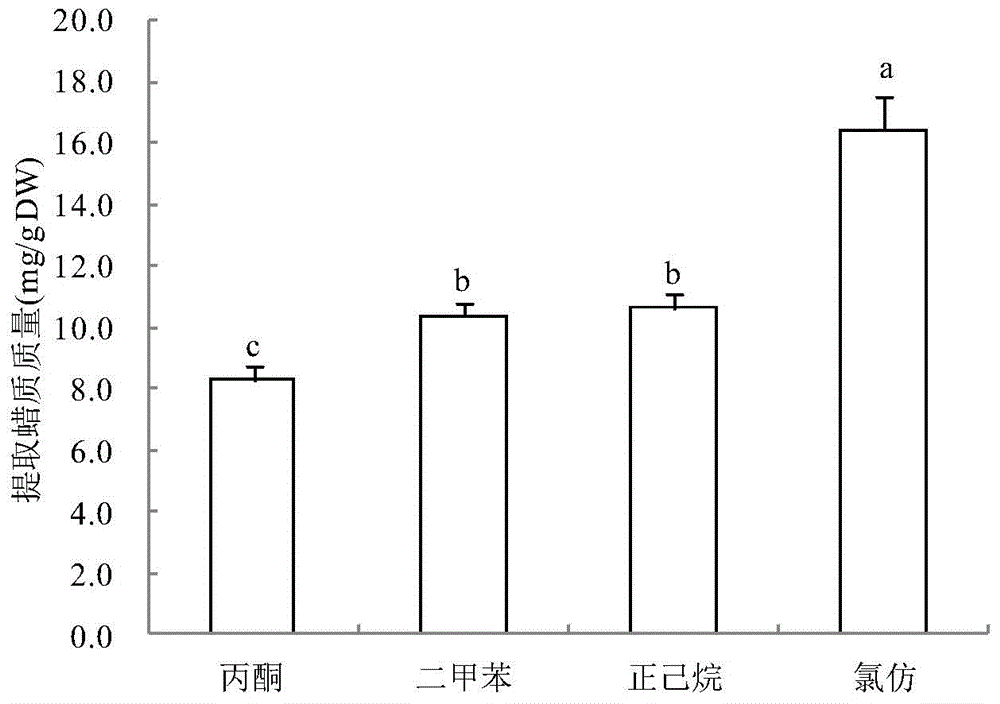

[0046] The influence of different extraction parameter conditions on the extraction effect:

[0047] The reagents used are: chloroform, n-hexane, acetone, and xylene, all of which are of analytical grade, and their main physical and chemical properties are listed in Table 2 below.

[0048] Physicochemical properties of organic reagents used in table 2

[0049]

[0050] 1. Comparison of the qualit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com