Seed crystal addition and atmosphere protection device for preparing high-purity gallium through crystallization method

A protection device and technology of crystallization method, applied in the direction of improving process efficiency, etc., can solve the problems of large influence of environmental atmosphere, lower production cost, inconvenient addition of crystal seeds, etc., so as to improve the purification yield, simplify the addition process, and reduce the crystallization. effect of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

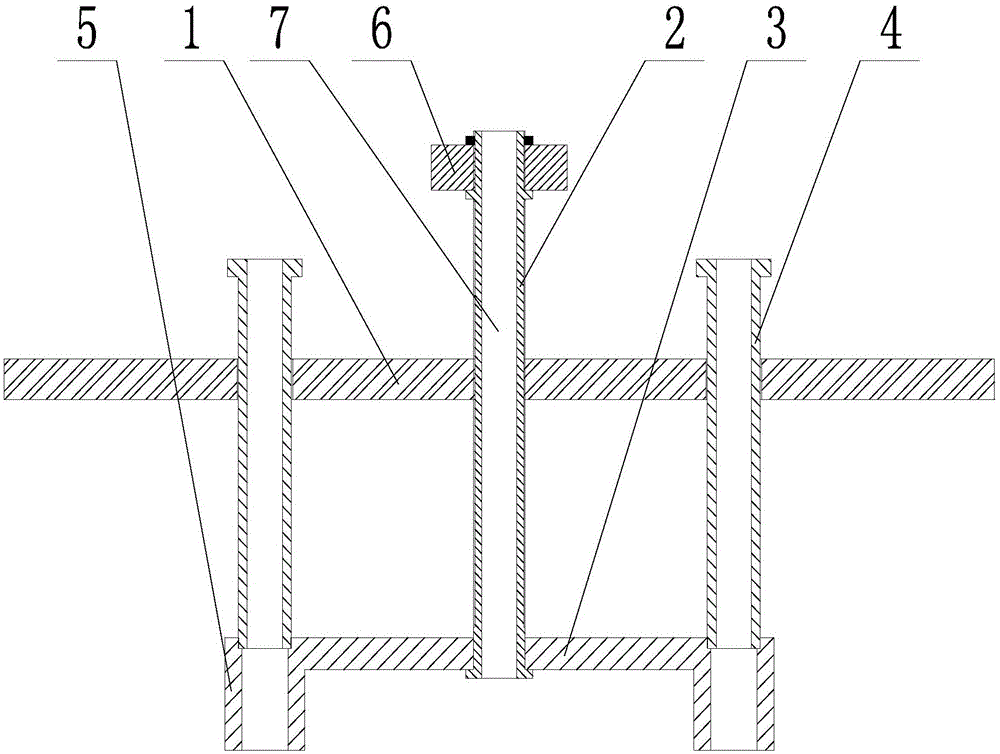

[0042] In this embodiment, the end cover 1 is made of plexiglass, the vertical pipes 4 are arranged at 4 places, the number of legs 5 is 4, the lifting rod 2 is a hollow rod, and the central channel of the lifting rod 2 is an air inlet channel 7.

[0043] First, 3 kg of liquid crude gallium with a purity of 4N is moved into the crystallizer, and the inventive seed crystal addition and atmosphere protection device is fixedly installed on the top of the crystallizer to ensure that the end cap 1 is sealed and connected to the top of the crystallizer; then through the air inlet channel 7 Pass an inert protective atmosphere into the crystallizer, and the inert protective atmosphere is high-purity nitrogen.

[0044] Refrigerate the crystallizer until the temperature of the crude gallium in the crystallizer drops to the crystallization critical temperature, adjust the height of the support 3, and keep the distance between the support 3 and the liquid surface of the crude gallium at 0....

Embodiment 2

[0049] In this embodiment, the end cap 1 is made of quartz glass, the vertical pipes 4 are arranged at 5 places, the number of legs 5 is 5, the lifting rod 2 is a hollow rod, and the central channel of the lifting rod 2 is an air inlet channel 7 .

[0050] First, 3 kg of liquid crude gallium with a purity of 4N is moved into the crystallizer, and the inventive seed crystal addition and atmosphere protection device is fixedly installed on the top of the crystallizer to ensure that the end cap 1 is sealed and connected to the top of the crystallizer; then through the air inlet channel 7 Pass an inert protective atmosphere into the crystallizer, and the inert protective atmosphere is high-purity argon.

[0051] Refrigerate the crystallizer until the temperature of the crude gallium in the crystallizer drops to the crystallization critical temperature, adjust the height of the support 3, and keep the distance between the support 3 and the liquid surface of the crude gallium at 0.5m...

Embodiment 3

[0056] In this embodiment, the end cover 1 is made of quartz glass, the vertical pipes 4 are arranged in 3 places, the number of legs 5 is 3, the lifting rod 2 is a solid rod, and the air inlet channel 7 is directly arranged on the end cover 1 .

[0057] First, 3 kg of liquid crude gallium with a purity of 4N is moved into the crystallizer, and the inventive seed crystal addition and atmosphere protection device is fixedly installed on the top of the crystallizer to ensure that the end cap 1 is sealed and connected to the top of the crystallizer; then through the air inlet channel 7 Pass an inert protective atmosphere into the crystallizer, and the inert protective atmosphere is high-purity nitrogen.

[0058] Refrigerate the crystallizer until the temperature of the crude gallium in the crystallizer drops to the crystallization critical temperature, adjust the height of the support 3, and keep the distance between the support 3 and the liquid surface of the crude gallium at 0.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com