Method for improving fermentation yield in production of neomycin sulfate and fermentation device

A neomycin sulfate and fermentation device technology, which is applied in the directions of microorganism-based methods, methods of supporting/fixing microorganisms, methods of sterilization, etc., can solve the complex resin addition and separation process, affect the fermentation efficiency, and limit the fermentation yield. and other problems, to achieve the effect of simplifying the resin addition process, improving the fermentation efficiency, and simplifying the separation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

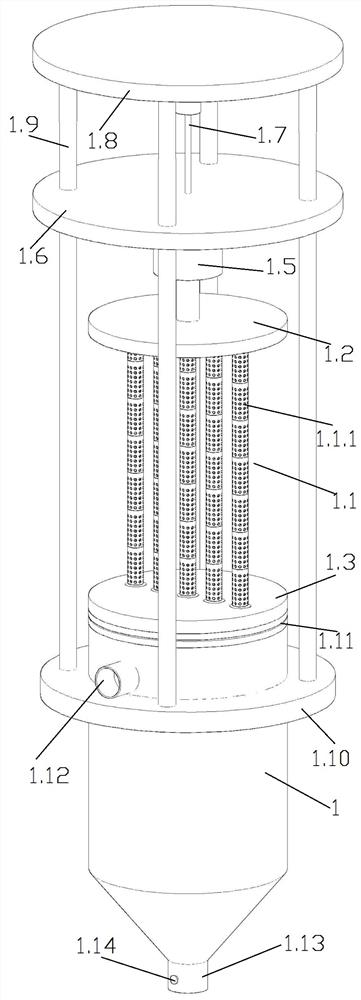

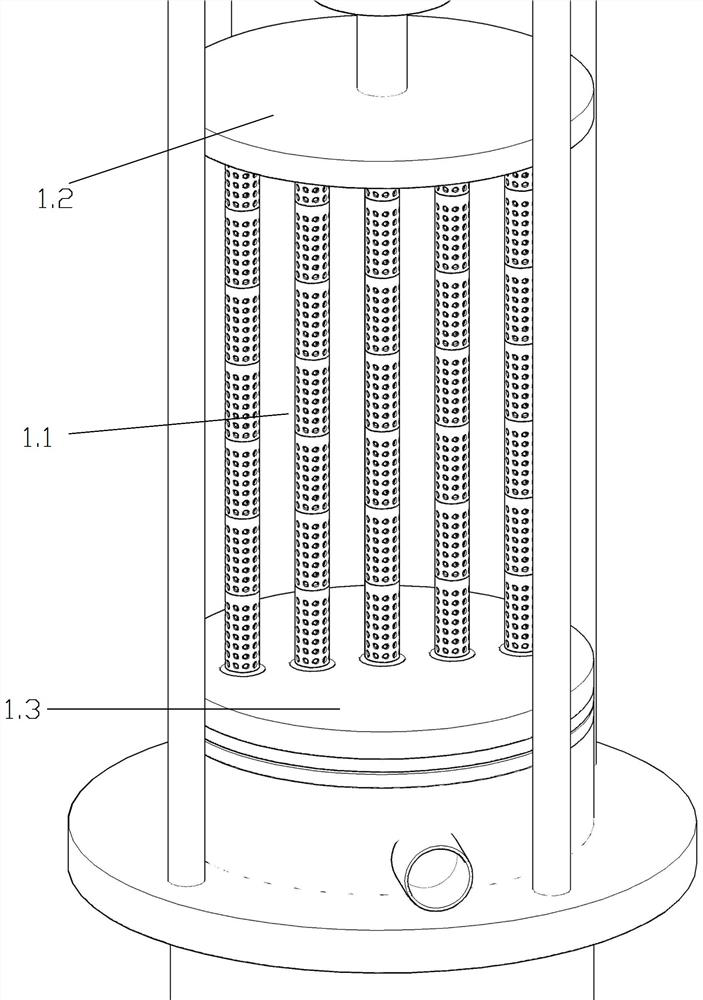

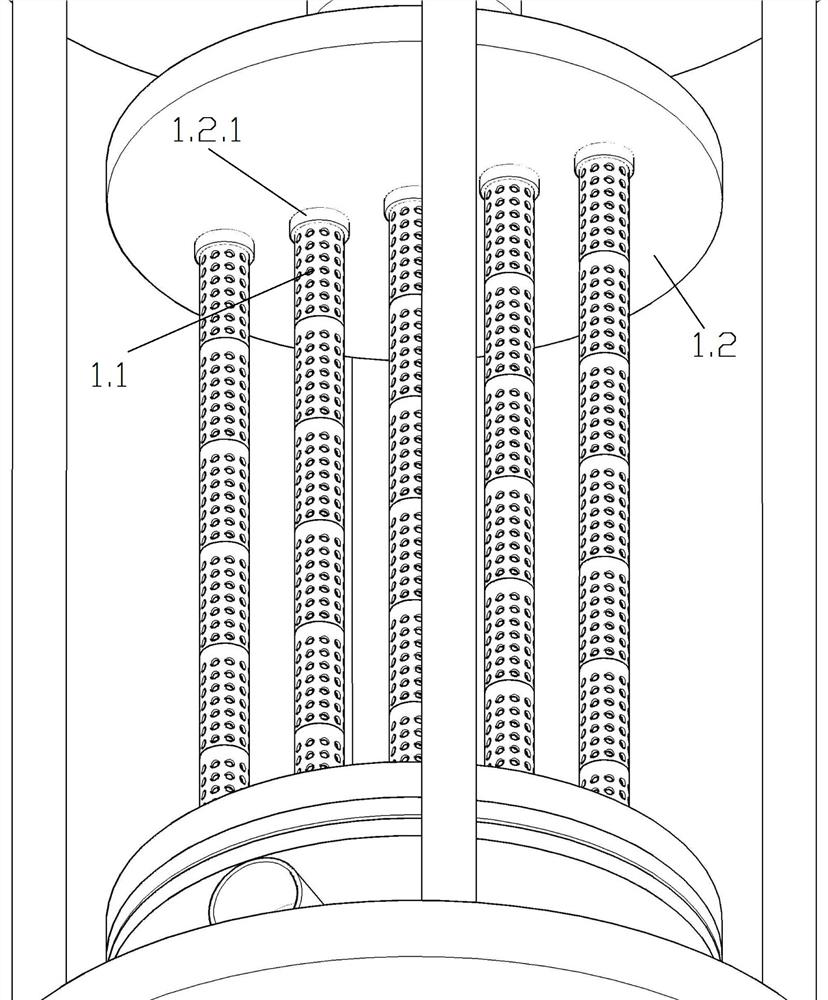

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0043] like Figures 1 to 6 Shown, a kind of method that improves neomycin sulfate to produce fermentation yield, it comprises the steps:

[0044] S1, inoculating the sandy soil spores into the slant medium, and preparing the slant spore suspension after cultivation;

[0045] S2, inserting the slant spore suspension into a seed tank equipped with a seed medium, and cultivating to obtain a seed liquid;

[0046] S3. Insert the seed liquid into the fermenter 1 equipped with the fermentation basal medium, control and stabilize the fermentation, then measure the reducing sugar and ammonia nitrogen, supplement the sugar material and ammonium sulfate solution according to the measured value, prepare the resin, sterilize and Standby after cooling, during the fermentation process, a quantitative amount of resin is added to the fermenter 1 as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com