Green corrosion inhibitor for inhibiting carbon steel from corrosion in seawater medium and preparation method and application of green corrosion inhibitor

A corrosion inhibitor and seawater technology, applied in the field of green corrosion inhibitor and its preparation, can solve the problems of large amount of corrosion inhibitor, poor thermal stability, and large amount of use, and achieve the goal of improving overall performance, reducing dosage, and low toxicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

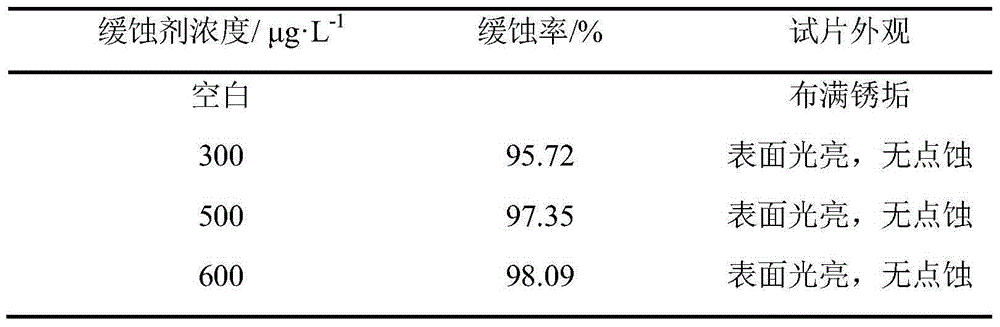

Examples

Embodiment 1

[0038] A green corrosion inhibitor for inhibiting the corrosion of carbon steel in salt water medium, its composition is: calcium gluconate, polyaspartic acid, sodium tungstate, sodium gluconate, dodecyl glucoside, isopropyl palmitate Ester and water, the parts by mass of each component are: 10 parts of calcium gluconate, 10 parts of polyaspartic acid, 10 parts of sodium tungstate, 30 parts of sodium gluconate, 10 parts of lauryl glucoside, palmitic acid 0.7 parts of isopropyl ester, 30 parts of water.

[0039] The preparation method of above-mentioned corrosion inhibitor is:

[0040] (a) first weigh 10 parts of calcium gluconate in proportion and dissolve in 30 parts of distilled water at 55° C., stir (stirring speed is 200 rpm) and dissolve to obtain calcium gluconate aqueous solution;

[0041] (b) Take 10 parts of sodium tungstate in proportion and add it to the calcium gluconate aqueous solution and stir (stirring speed is 200rpm) to dissolve;

[0042] (c) Then add 30 pa...

Embodiment 2

[0059] A green corrosion inhibitor for inhibiting the corrosion of carbon steel in salt water medium, its composition is: calcium gluconate, polyaspartic acid, sodium tungstate, sodium gluconate, dodecyl glucoside, isopropyl palmitate ester and water, the parts by mass of each component are: 15 parts of calcium gluconate, 5 parts of polyaspartic acid, 20 parts of sodium tungstate, 20 parts of sodium gluconate, 13 parts of lauryl glucoside, palmitic acid 0.5 parts of isopropyl ester, 35 parts of water.

[0060] The preparation method of above-mentioned corrosion inhibitor is:

[0061] (a) First take by weighing 15 parts of calcium gluconate in proportion and be dissolved in 35 parts of distilled water at 50 DEG C, stir (stirring speed is 200rpm) dissolve and obtain calcium gluconate aqueous solution;

[0062] (b) Take 20 parts of sodium tungstate in proportion and add it to the calcium gluconate aqueous solution and stir (stirring speed is 200rpm) to dissolve;

[0063] (c) Th...

Embodiment 3

[0068] A green corrosion inhibitor for inhibiting the corrosion of carbon steel in salt water medium, its composition is: calcium gluconate, polyaspartic acid, sodium tungstate, sodium gluconate, dodecyl glucoside, isopropyl palmitate Ester and water, the parts by mass of each component are: 5 parts of calcium gluconate, 15 parts of polyaspartic acid, 5 parts of sodium tungstate, 40 parts of sodium gluconate, 5 parts of lauryl glucoside, palmitic acid 0.8 parts of isopropyl ester, 25 parts of water.

[0069] The preparation method of above-mentioned corrosion inhibitor is:

[0070] (a) First take 5 parts of calcium gluconate in proportion and dissolve it in 25 parts of distilled water at 60° C., stir (stirring speed is 150 rpm) and dissolve to obtain an aqueous solution of calcium gluconate;

[0071] (b) Take 5 parts of sodium tungstate in proportion and add it to the calcium gluconate aqueous solution and stir (stirring speed is 150rpm) to dissolve;

[0072] (c) Then add 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com