Production method for wet-process phosphoric acid byproduct alpha semi-hydrated gypsum whiskers

A technology of hemihydrate gypsum and wet-process phosphoric acid, which is applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of high content of phosphorus pentoxide, reduction of whisker phosphorus content, and unapplied large-scale industrial production , to achieve the effects of recycling, improving production efficiency, shortening the time required for reaction and aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

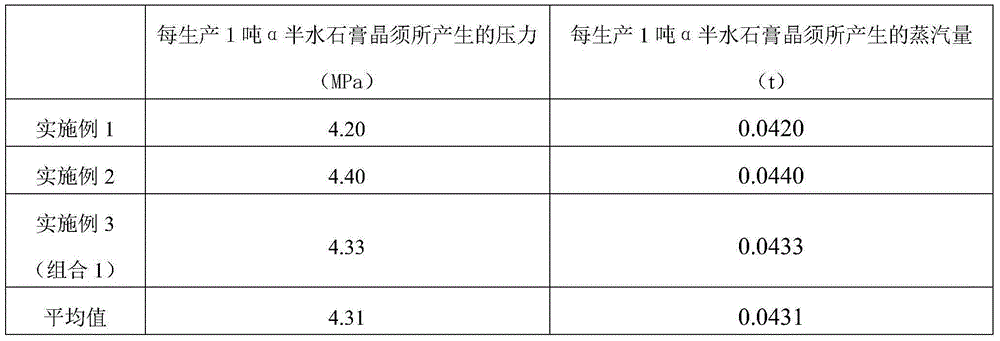

Embodiment 1

[0052] Embodiment 1. The phosphate rock is collected in Kailin, Guizhou; the content of phosphorus pentoxide in the phosphate rock is about 30%.

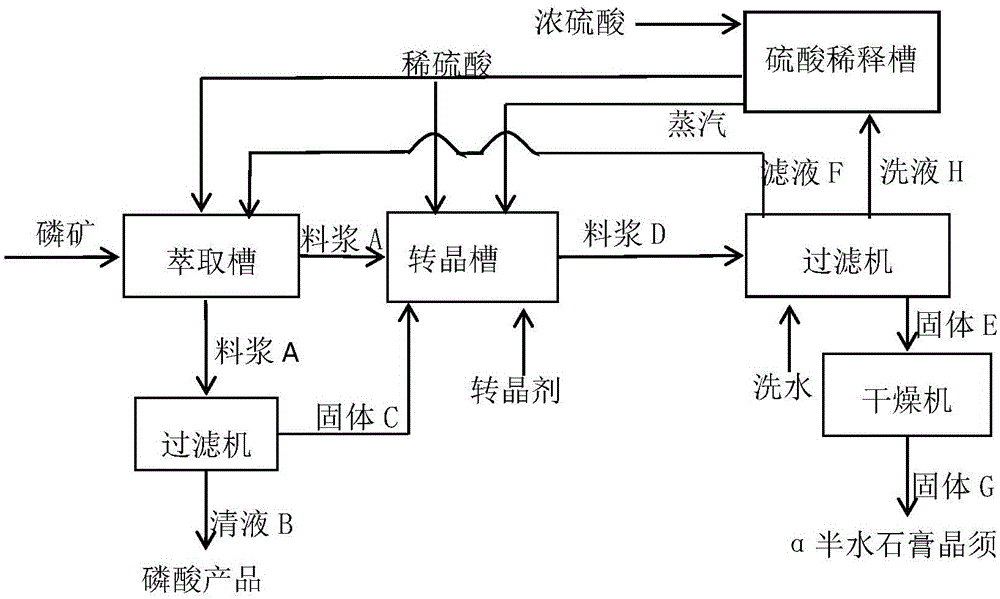

[0053] A kind of production method of wet-process phosphoric acid by-product α hemihydrate gypsum whisker, comprises the steps:

[0054] (1) First, the phosphate rock powder and the dilute sulfuric acid with a mass concentration of 20% are added to the extraction tank at a solid-to-liquid mass ratio of 1:5, the fineness of the phosphate rock powder is 80 mesh, and the content of phosphorus pentoxide in the phosphate rock is 30% , under constant stirring, control the temperature of the extraction tank at 25°C for extraction reaction for 30 minutes to obtain mixed slurry A;

[0055] (2) 1 / 8 of the volume of the mixed slurry A obtained in step (1) is separated through a filter for solid-liquid separation, and the separated clear liquid B is sent to the acid store as finished phosphoric acid, and the solid C is mixed with the remaining ...

Embodiment 2

[0062] Embodiment 2, the phosphate rock is collected in Lufa, Guizhou; the content of phosphorus pentoxide in the phosphate rock is 29%.

[0063] A kind of production method of wet-process phosphoric acid by-product α hemihydrate gypsum whisker, comprises the steps:

[0064] (1) Firstly, phosphate rock powder and dilute sulfuric acid with a mass concentration of 30% are added to the extraction tank at a solid-to-liquid mass ratio of 1:4. The fineness of the phosphate rock powder is 100 mesh, and the content of phosphorus pentoxide in the phosphate rock is 29%. , under continuous stirring, control the temperature of the extraction tank at 35° C. to carry out the extraction reaction for 50 minutes to obtain the mixed slurry A.

[0065] (2) 1 / 3 of the mixed slurry A obtained in the step (1) is separated from the volume through a filter for solid-liquid separation, and the separated clear liquid B is sent to the acid store as finished phosphoric acid, and the solid C is mixed with...

Embodiment 3

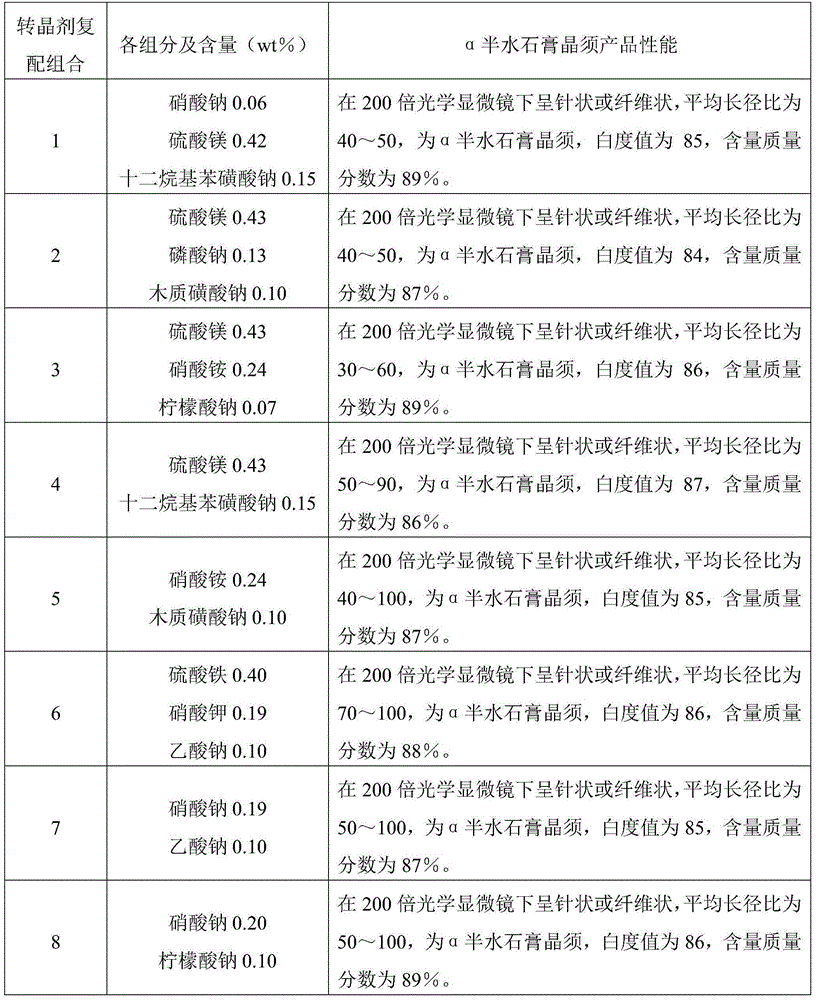

[0073] A kind of method of producing wet-process phosphoric acid by-product α hemihydrate gypsum whiskers described in Example 1, the difference is that the crystal modifier component and content of use are different, as shown in table 1:

[0074] Table 1 crystal transformation agent component, content and the performance that obtain product

[0075]

[0076] It can be seen from the above table that the aspect ratio of the α hemihydrate gypsum whiskers prepared by the present invention ranges from 10 to 100, and the aspect ratio can be controlled. By adjusting the formula of the crystal modifier, α hemihydrate gypsum crystals with different aspect ratios can be prepared. Must be used to apply to different market demands.

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com