A brake pad that does not damage the disc

A technology of brake pads and iron sources, applied in friction linings, other chemical processes, chemical instruments and methods, etc., can solve the problems of wear, wheel brake disc wear, affecting the service life of brake discs, etc. The effect of service life, stable friction performance and stable friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

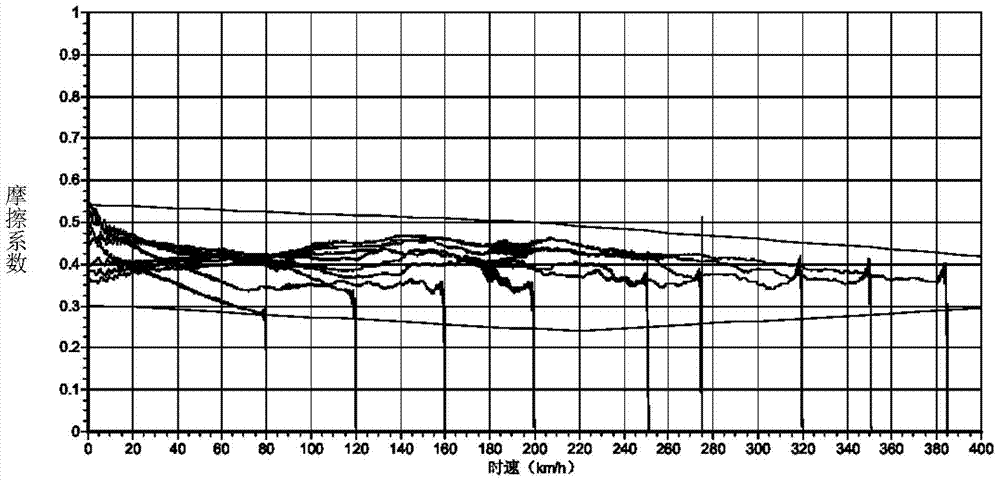

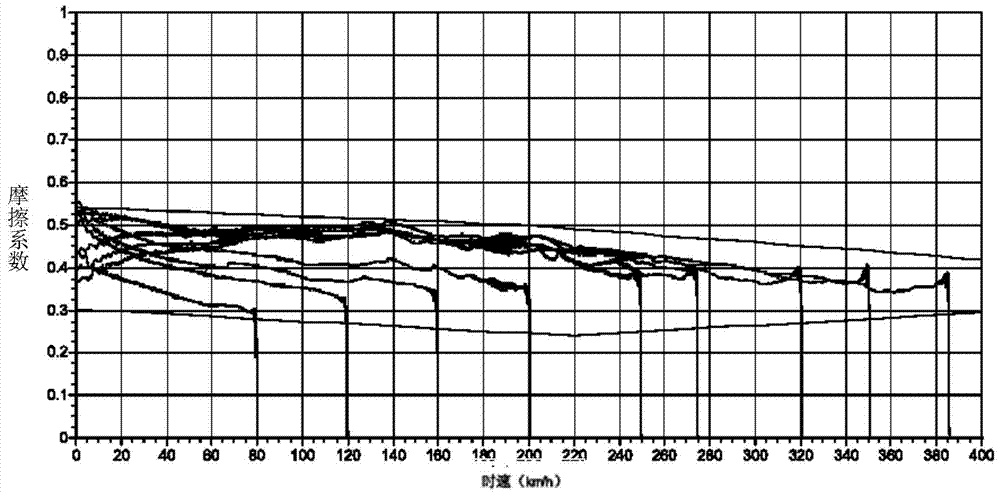

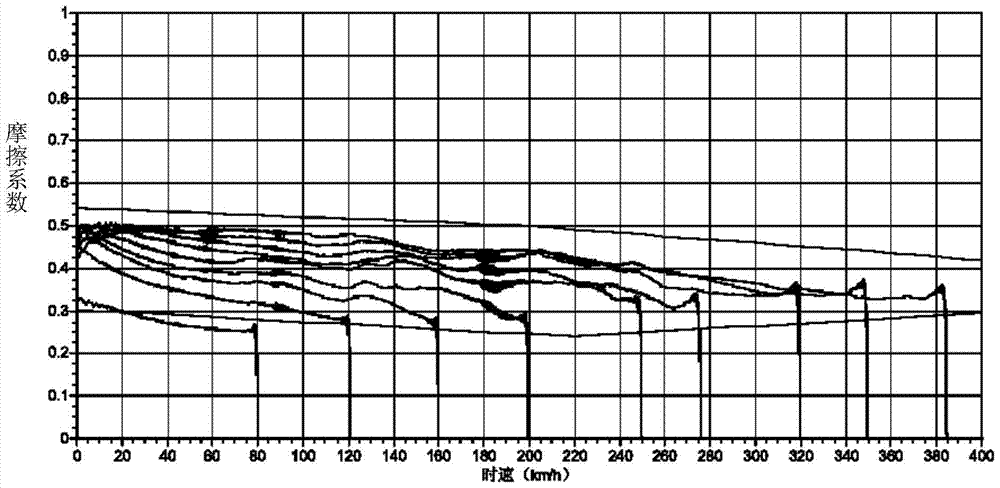

Image

Examples

Embodiment 1

[0051] This embodiment provides a brake pad that does not damage the disc, including the following raw material components:

[0052] Electrolytic copper powder, 50 parts by weight;

[0053] Reduced iron powder, 6 parts by weight;

[0054] Air atomized tin powder, 7 parts by weight;

[0055] Electrolytic manganese powder, 2 parts by weight;

[0056] Electrolytic chromium powder, 3 parts by weight;

[0057] Fluorite, 1 part by weight, containing CaF in the fluorite 2 The quality score is 94%;

[0058] Graphite, 16 parts by weight;

[0059] Aluminum oxide, 1 part by weight.

[0060] The brake pad that does not damage the disc is prepared by the following method:

[0061] (1) Weigh each raw material component according to the above parts by weight and place it in a ball mill for thorough mixing for 4 hours to obtain the mixture;

[0062](2) Carrying out mold molding to the compound described in step (1), obtains green body, the pressure that carries out described molding i...

Embodiment 2

[0065] This embodiment provides a brake pad that does not damage the disc, including the following raw material components:

[0066] Reduced copper powder, 58 parts by weight;

[0067] A mixture of water atomized iron powder and ferrochrome powder, 12 parts by weight; wherein, the weight percentage of the ferrochrome powder in the water atomized iron powder is 4%;

[0068] Electrolytic tin powder, 10 parts by weight;

[0069] Atomized manganese powder, 5 parts by weight;

[0070] Atomized chromium powder, 5 parts by weight;

[0071] Fluorite, with CaF 2 The mass fraction is 98%, 4 parts by weight;

[0072] Graphite, 24 parts by weight;

[0073] Aluminum oxide, 3 parts by weight.

[0074] The brake pad that does not damage the disc is prepared by the following method:

[0075] (1) Weigh each raw material component according to the above parts by weight and place it in a ball mill for thorough mixing for 6 hours to obtain the mixture;

[0076] (2) Carrying out mold moldi...

Embodiment 3

[0079] This embodiment provides a brake pad that does not damage the disc, including the following raw material components:

[0080] Water atomized copper powder, 52 parts by weight;

[0081] A mixture of water-atomized iron powder and nickel-iron alloy powder, 5 parts by weight; wherein, the weight percentage of the water-atomized iron powder accounted for by the nickel-iron alloy powder is 5%;

[0082] Chemical precipitation tin powder, 8 parts by weight;

[0083] Ball milled manganese powder, 3 parts by weight;

[0084] Ball milled chromium powder, 3 parts by weight;

[0085] Fluorite, with CaF 2 The mass fraction is 96%, 2 parts by weight;

[0086] Graphite, 17 parts by weight;

[0087] Aluminum oxide, 2 parts by weight.

[0088] The brake pad that does not damage the disc is prepared by the following method:

[0089] (1) Weigh each raw material component according to the above parts by weight and place it in a ball mill for thorough mixing for 6 hours to obtain the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com