A waste flue gas heat recovery system and its application method

A waste heat recovery system and heat recovery technology, applied in the field of heat recovery systems, can solve the problems of low heat exchange efficiency, increased cost, poor equipment applicability, etc., and achieve the effect of good thermal vibration resistance and shortened service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

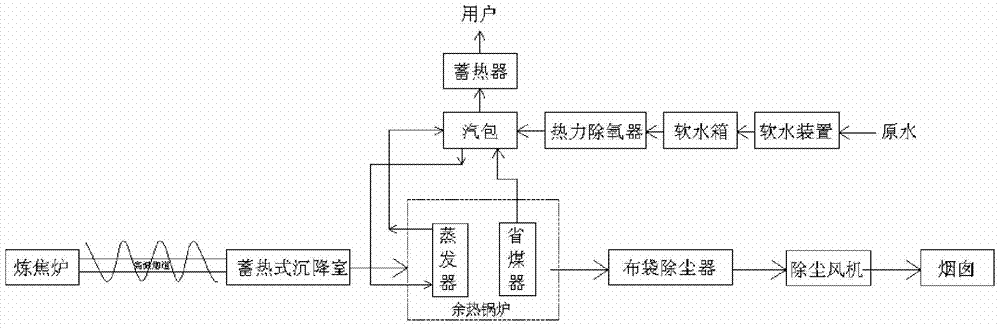

[0032] A waste flue gas heat recovery system provided in this embodiment has a structure such as figure 1 As shown, it includes the coke oven, waste heat recovery system and chimney, the inlet end of the waste heat recovery system is connected to the coke oven, and the outlet end of the waste heat recovery system is connected to the chimney, where:

[0033] The waste heat recovery system includes a steam drum, a waste heat boiler and a heat accumulator. The waste heat boiler is equipped with an evaporator and an economizer along the direction of flue gas circulation. The top of the waste heat boiler is provided with a steam drum that provides steam to users. The outlet of the steam drum The end is connected to the heat accumulator, the outlet of the economizer is connected to the steam drum, the downcomer of the steam drum is connected to the inlet of the evaporator, and the outlet of the steam-water mixture of the evaporator is connected to the steam drum;

[0034] The waste ...

Embodiment 2

[0045] A waste flue gas heat recovery system provided in this embodiment has a structure such as figure 1As shown, it includes the coke oven, waste heat recovery system and chimney, the inlet end of the waste heat recovery system is connected to the coke oven, and the outlet end of the waste heat recovery system is connected to the chimney, where:

[0046] The waste heat recovery system includes a steam drum, a waste heat boiler and a heat accumulator. The waste heat boiler is equipped with an evaporator and an economizer along the direction of flue gas circulation. The top of the waste heat boiler is provided with a steam drum that provides steam to users. The outlet of the steam drum The end is connected to the heat accumulator, the outlet of the economizer is connected to the steam drum, the downcomer of the steam drum is connected to the inlet of the evaporator, and the outlet of the steam-water mixture of the evaporator is connected to the steam drum;

[0047] The waste h...

Embodiment 3

[0058] A waste flue gas heat recovery system provided in this embodiment has a structure such as figure 1 As shown, it includes the coke oven, waste heat recovery system and chimney, the inlet end of the waste heat recovery system is connected to the coke oven, and the outlet end of the waste heat recovery system is connected to the chimney, where:

[0059] The waste heat recovery system includes a steam drum, a waste heat boiler and a heat accumulator. The waste heat boiler is equipped with an evaporator and an economizer along the direction of flue gas circulation. The top of the waste heat boiler is provided with a steam drum that provides steam to users. The outlet of the steam drum The end is connected to the heat accumulator, the outlet of the economizer is connected to the steam drum, the downcomer of the steam drum is connected to the inlet of the evaporator, and the outlet of the steam-water mixture of the evaporator is connected to the steam drum;

[0060] The waste ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com