Online powder detecting device and measuring method based on laser-induced breakdown spectroscopy

A laser-induced breakdown and detection device technology, applied in the field of atomic emission spectrometry, can solve the problems of powder scattering, contamination of optical components, low repeatability of laser-induced breakdown spectrometry measurement, etc., to ensure stability and accuracy. , Enhance the effect of spectral signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

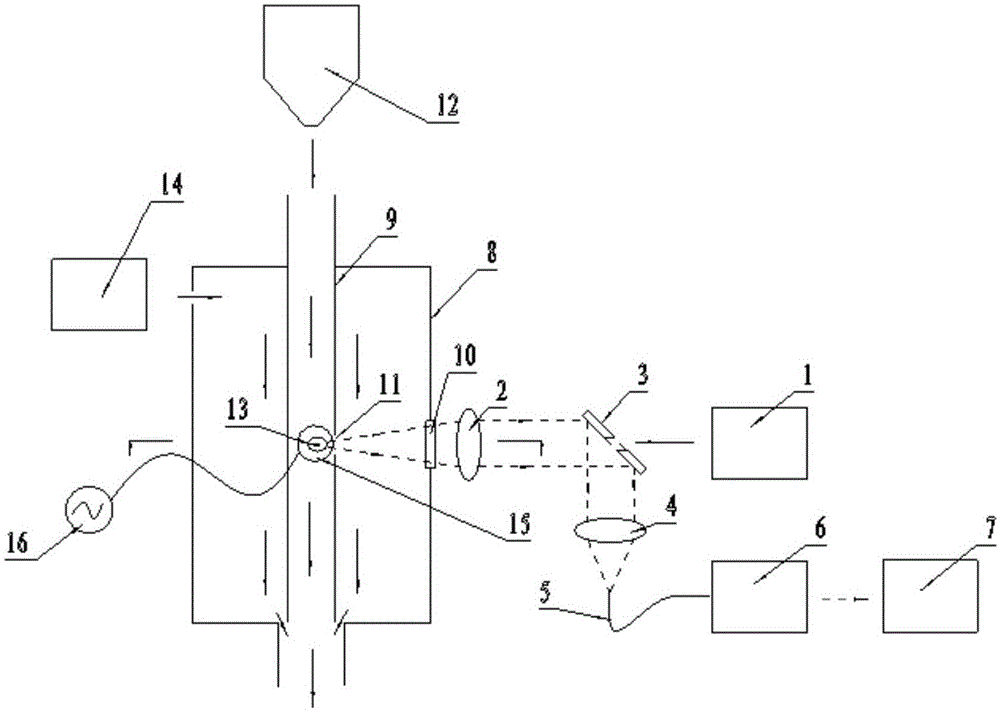

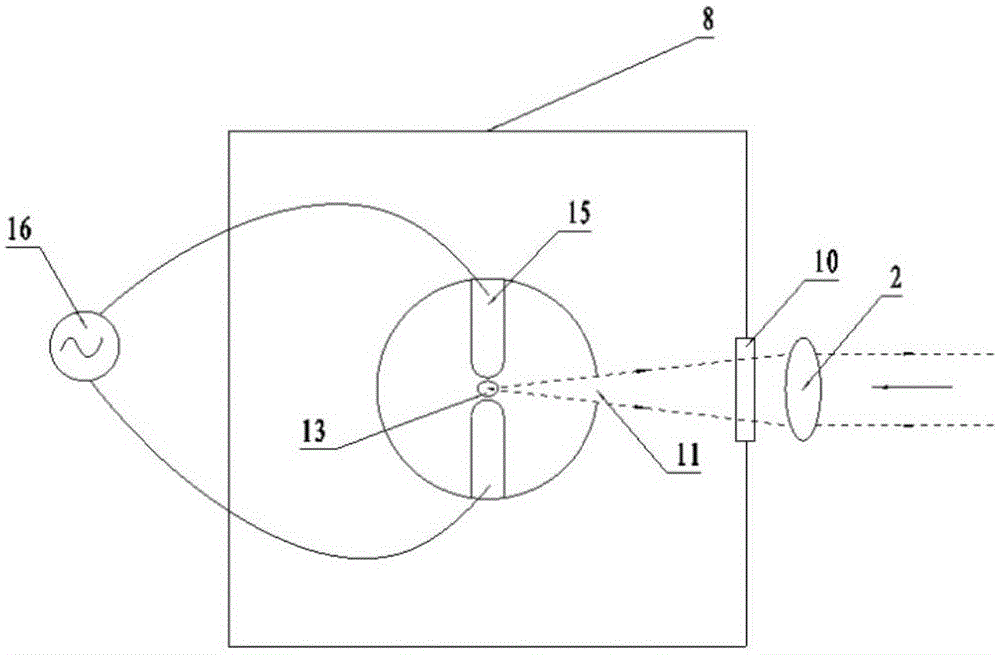

[0024] Taking coal powder detection as an example to illustrate the device of the present invention. An online powder detection device based on laser-induced breakdown spectroscopy and its measurement method, the device includes a laser-induced breakdown spectroscopy system and a pulverized coal powder sampling system: the laser-induced breakdown system includes an incident unit, a spectral signal receiving unit and data analysis and processing Unit 7; the incident unit contains a pulse laser 1 and a focusing lens 2, and the spectral signal receiving unit contains a reflector 3, a collection lens 4, an optical fiber 5 and a spectrometer 6; the center of the reflector has a small hole with a diameter of 5-10mm, and the laser can Pass through the small hole, focus through the focusing lens and hit the pulverized coal sample. The pulverized coal powder sampling system comprises a pulverized coal jet pump 12, a pulverized coal powder conveying pipeline 9, a sample chamber 8, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com