Method for determination of content of kappa-casein in cow milk

A technology of casein and milk, applied in the direction of measuring devices, material analysis by electromagnetic means, instruments, etc., can solve problems that need to be improved, and achieve the effect of high repeatability, strong accuracy, and short detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

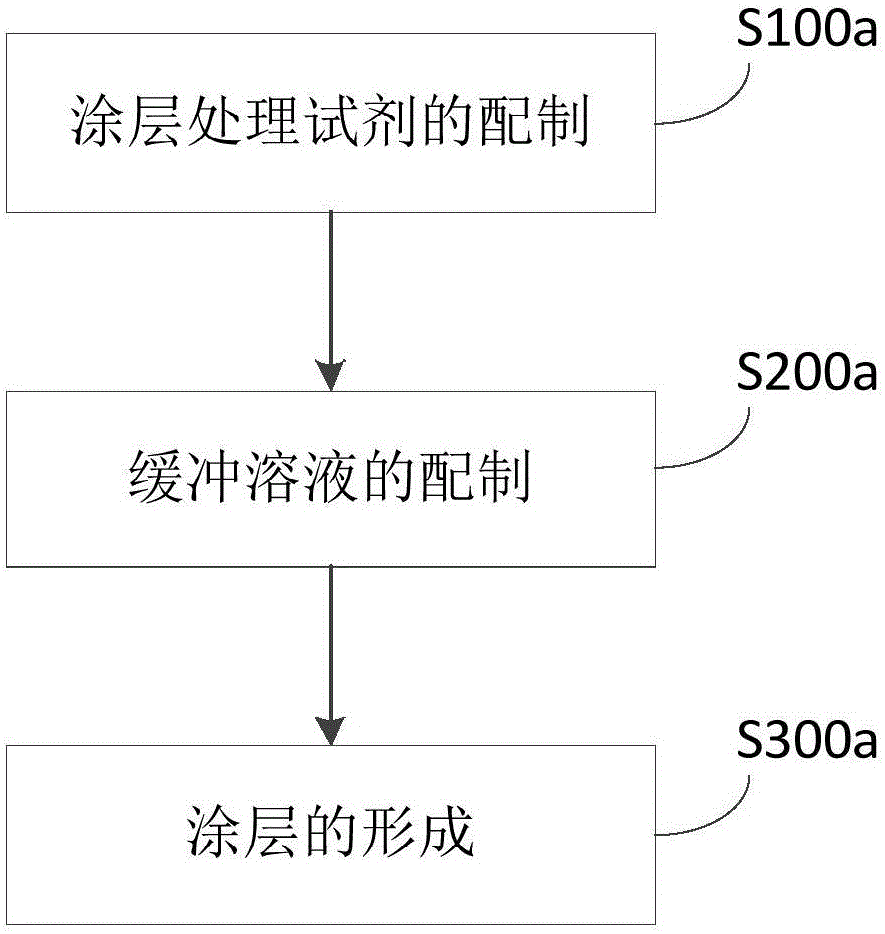

[0077] In this example, the kappa-casein content in raw milk was determined by the following steps:

[0078] (1) Raw milk pretreatment

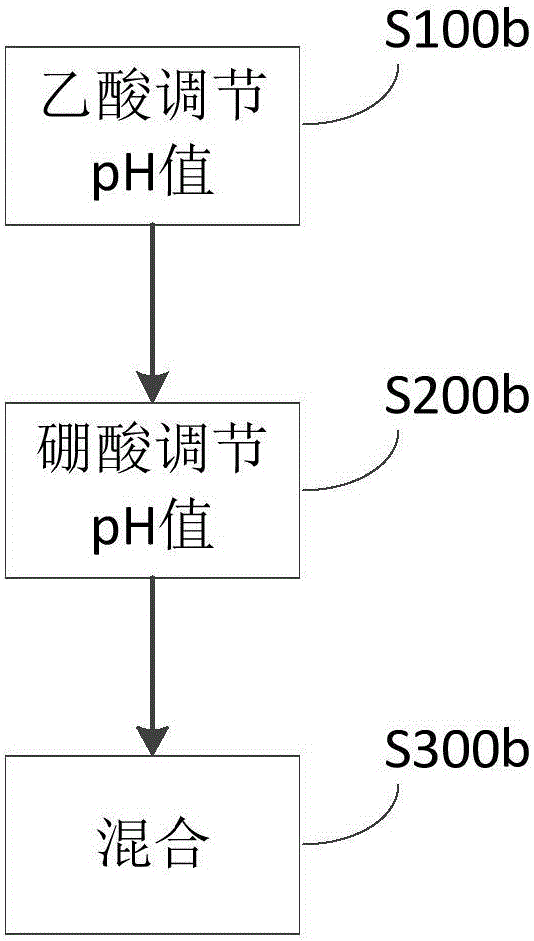

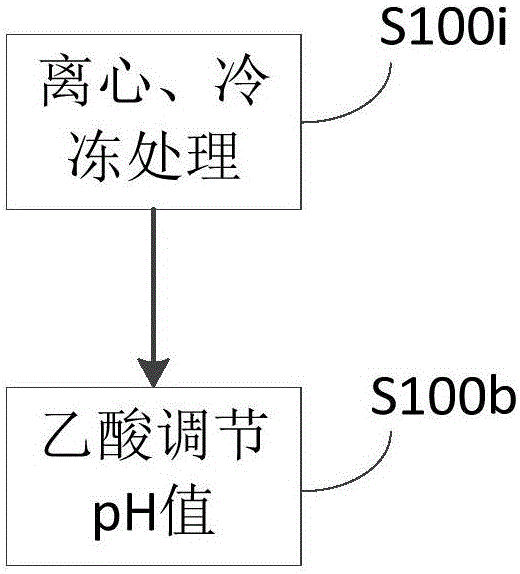

[0079] Take 30ml of raw milk to be tested, put it in a 50ml centrifuge tube, and centrifuge at 6000r / min for 20 minutes to remove milk fat; then put it in a -40°C refrigerator for 20 minutes; take it out and return it to room temperature, and use 40mmol / L acetic acid aqueous solution to adjust the pH to 4.6, centrifuge at 6000r / min for 20 minutes, discard the supernatant, wash with water 3 times, centrifuge at 6000r / min for 20 minutes, discard the supernatant, and then wash with 40mmol / L boric acid The pH of the solution was adjusted to 6.6 to prepare the stock solution to be tested. Take 10ml of the stock solution to be tested, add 3.6g of urea and 0.05g of dithiothreitol (DTT), shake and mix to prepare the solution to be tested.

[0080] (2) Activation of uncoated capillary

[0081] Cut off an uncoated quartz capillary column with an in...

Embodiment 2

[0089] In this example, the kappa-casein content in raw milk was determined by the following steps:

[0090] (1) Raw milk pretreatment

[0091]Take 30ml of raw milk to be tested, put it in a 50ml centrifuge tube, and centrifuge at 3000r / min for 30 minutes to remove milk fat; then place it in a -40°C refrigerator for 20 minutes; take it out and return it to room temperature, and use 40mmol / L acetic acid aqueous solution to adjust the pH to 4.6, centrifuge at 3000r / min for 30 minutes, discard the supernatant, wash with water 3 times, centrifuge at 3000r / min for 30 minutes, discard the supernatant, and then wash with 40mmol / L boric acid The pH of the solution was adjusted to 6.6 to prepare the stock solution to be tested. Take 10ml of the stock solution to be tested, add 3.6g of urea and 0.05g of dithiothreitol (DTT), shake and mix to prepare the solution to be tested.

[0092] (2) Activation of uncoated capillary

[0093] Cut off an uncoated quartz capillary column with an i...

Embodiment 3

[0101] In this example, the kappa-casein content in raw milk was determined by the following steps:

[0102] (1) Raw milk pretreatment

[0103] Take 30ml of raw milk to be tested, put it in a 50ml centrifuge tube, and centrifuge at 10000r / min for 10 minutes to remove milk fat; then put it in a -40°C refrigerator for 10 minutes; take it out and return it to room temperature, and use 40mmol / L acetic acid aqueous solution to adjust the pH to 4.6, centrifuge at 3000r / min for 30 minutes, discard the supernatant, wash with water three times, centrifuge at 10000r / min for 10 minutes, discard the supernatant, and then wash with 40mmol / L boric acid The pH of the solution was adjusted to 6.6 to prepare the stock solution to be tested. Take 10ml of the stock solution to be tested, add 3.6g of urea and 0.05g of dithiothreitol (DTT), shake and mix to prepare the solution to be tested.

[0104] (2) Activation of uncoated capillary

[0105] Cut off an uncoated quartz capillary column with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Total length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com