High-capacity lithium ion battery anode material and preparing method thereof

A lithium-ion battery and anode material technology, which is applied in the field of high-capacity lithium-ion battery anode materials and its preparation, can solve the problems that the battery capacity of lithium-ion battery anode materials needs to be improved, achieve high specific energy, suppress volume expansion, prevent powder material shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

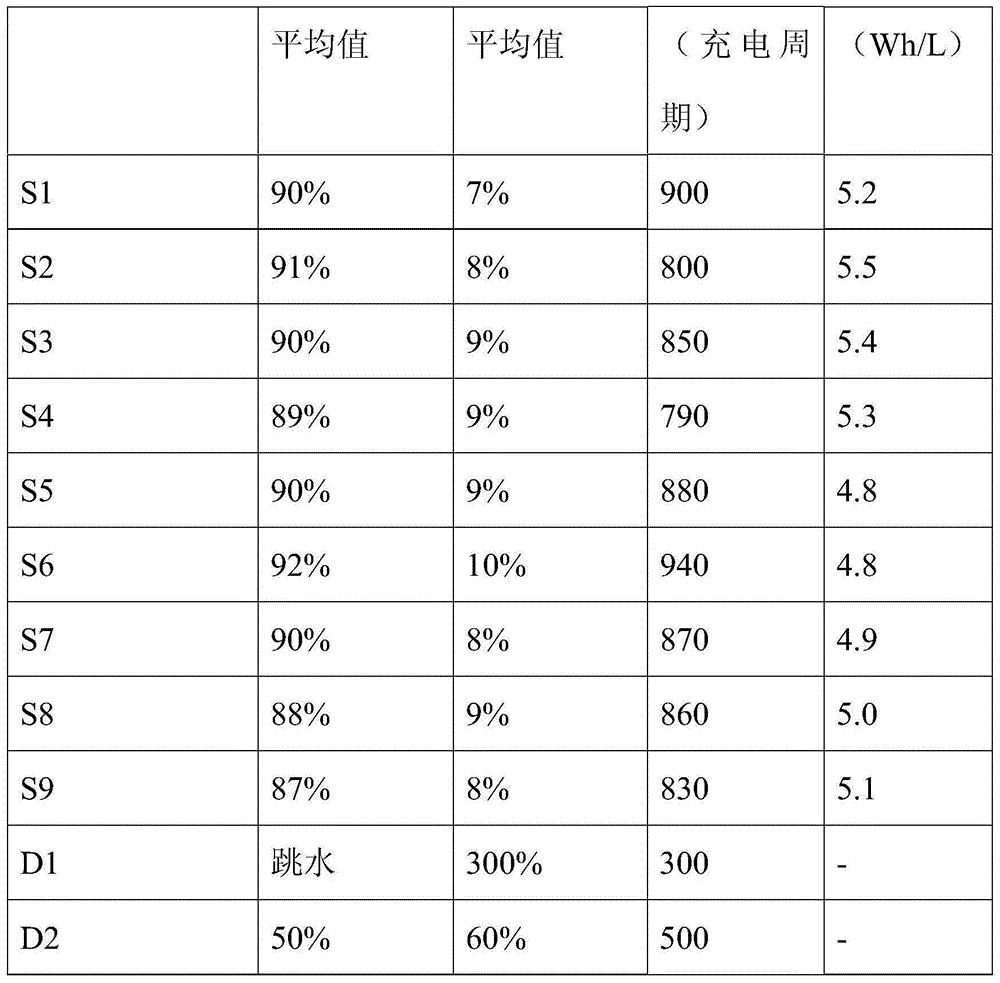

Examples

Embodiment 1

[0034] Embodiment 1, a kind of high-capacity lithium-ion battery anode material provided in this embodiment, comprises solid electrolyte layer and nickel oxide supported graphene composite, nickel oxide supported graphene composite is dispersed in the solid electrolyte layer, nickel oxide loaded graphite The particle size of the ene complex is 300 nm, and the outer surface of the solid electrolyte layer is also coated with a conductive coating layer. Wherein, the nickel oxide-loaded graphene composite is distributed in the solid electrolyte layer in the form of a network. Wherein, the solid electrolyte in the solid electrolyte layer is lithium nitride, and the material of the conductive coating layer is carbon. Wherein the thickness of the conductive coating layer is 1 μm.

Embodiment 2

[0035] Embodiment 2 is different from Embodiment 1 in that the solid electrolyte in the solid electrolyte layer is lithium silicate, the particle size of the nickel oxide-loaded graphene composite is 200nm, the material of the conductive coating is polyacetylene, and the conductive coating The thickness of the layer is 2 μm.

Embodiment 3

[0036] Embodiment 3 is different from Embodiment 1 in that the solid electrolyte in the solid electrolyte layer is lithium borate, the particle size of the nickel oxide-supported graphene composite is 800nm, the material of the conductive coating is polythiophene, and the conductive coating is The thickness is 3 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com