A recovery device and method for carbon disulfide in the production process of xanthate

A production process, technology of carbon disulfide, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., can solve problems such as impossible economic benefit of carbon disulfide oxidative decomposition, failure to meet carbon disulfide emission standards, large amount of sodium hypochlorite used as a working medium, etc., to achieve Significant energy saving effect, simple solvent follow-up treatment, and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

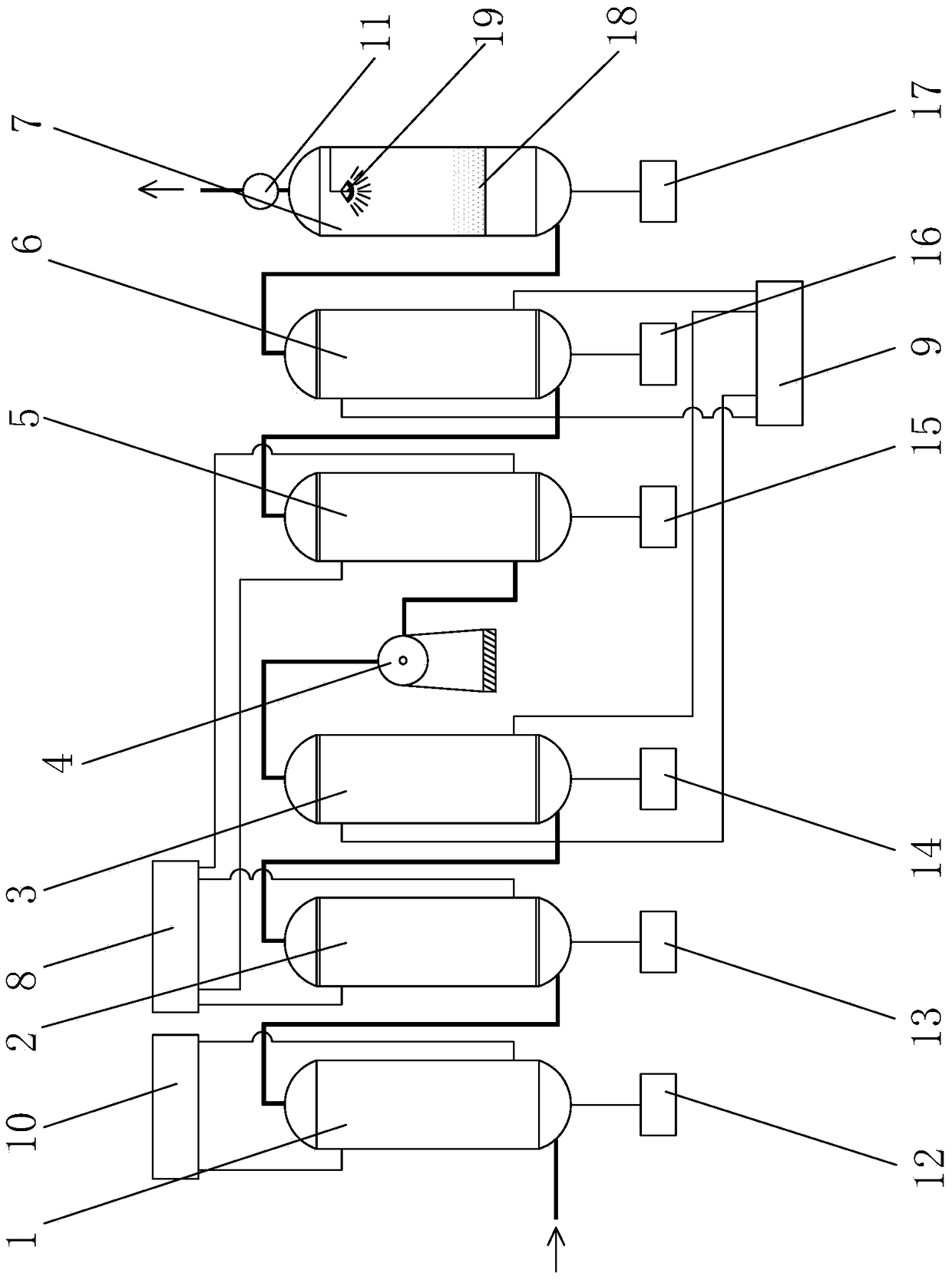

[0045] Such as figure 1 As shown, the recovery device of carbon disulfide in the xanthate production process of the present embodiment comprises a deduster 1, a primary condenser 2, a primary cryocooler 3, a secondary condenser 5, a secondary cryocooler 6 and an absorber connected successively. Tower 7;

[0046] The lower part of the dust collector 1 is provided with an air inlet and a dust outlet, and the upper part of the dust collector 1 is provided with an exhaust port. The primary condenser 2, primary cryocooler 3, and secondary condenser 5 are and the bottom of the secondary cryocooler 6 are all provided with an air inlet, a liquid outlet and a refrigerant inlet, and the primary condenser 2, the primary cryocooler 3, the secondary condenser 5 and the secondary cryocooler 6 The upper part of the absorption tower 7 is provided with an exhaust port and a refrigerant outlet, the lower part of the absorption tower 7 is provided with an air inlet and a liquid discharge port, ...

Embodiment 2

[0056] to combine figure 1 , the present embodiment reclaims the method for carbon disulfide from the gas that produces in the xanthate production process, comprises the following steps:

[0057] Step 1. Dust removal: The gas generated during the xanthate production process is passed into the dust collector 1 through the air inlet of the dust collector 1 for dust removal treatment, so that the dust in the gas settles and gathers at the bottom of the dust collector 1, and finally is discharged The dust port is discharged into the dust collection tank 12, and the gas after dust removal is discharged from the exhaust port of the dust collector 1, and enters the next step of the first-stage condensation process;

[0058] In order to improve the dust removal efficiency, in this embodiment, the vacuum pump 4 is preferably used to evacuate the dust collector 1 to a vacuum degree of -0.08MPa, and the heater 10 is preferably used to heat the dust collector 1 so that the internal temper...

Embodiment 3

[0076] to combine figure 1, the present embodiment reclaims the method for carbon disulfide from the gas that produces in the xanthate production process, comprises the following steps:

[0077] Step 1. Dust removal: The gas generated during the xanthate production process is passed into the dust collector 1 through the air inlet of the dust collector 1 for dust removal treatment, so that the dust in the gas settles and gathers at the bottom of the dust collector 1, and finally is discharged The dust port is discharged into the dust collection tank 12, and the gas after dust removal is discharged from the exhaust port and enters the next step of the first-level condensation process;

[0078] In order to improve the dust removal efficiency, in this embodiment, the vacuum pump 4 is preferably used to evacuate the dust collector 1 to a vacuum degree of -0.07MPa, and the heater 10 is preferably used to heat the dust collector 1 so that the internal temperature of the dust collecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com