1, 2-dichloroethane selective hydrodechlorination reaction catalyst and preparation method and application thereof

A dichloroethane, hydrodechlorination technology, applied in the direction of hydrocarbon production from halogen-containing organic compounds, bulk chemical production, etc., can solve the problems of inability to fully exert dechlorination ability, low metal utilization rate, and damage to human health , to achieve good economic benefits, large industrial value, and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 Catalyst and its preparation

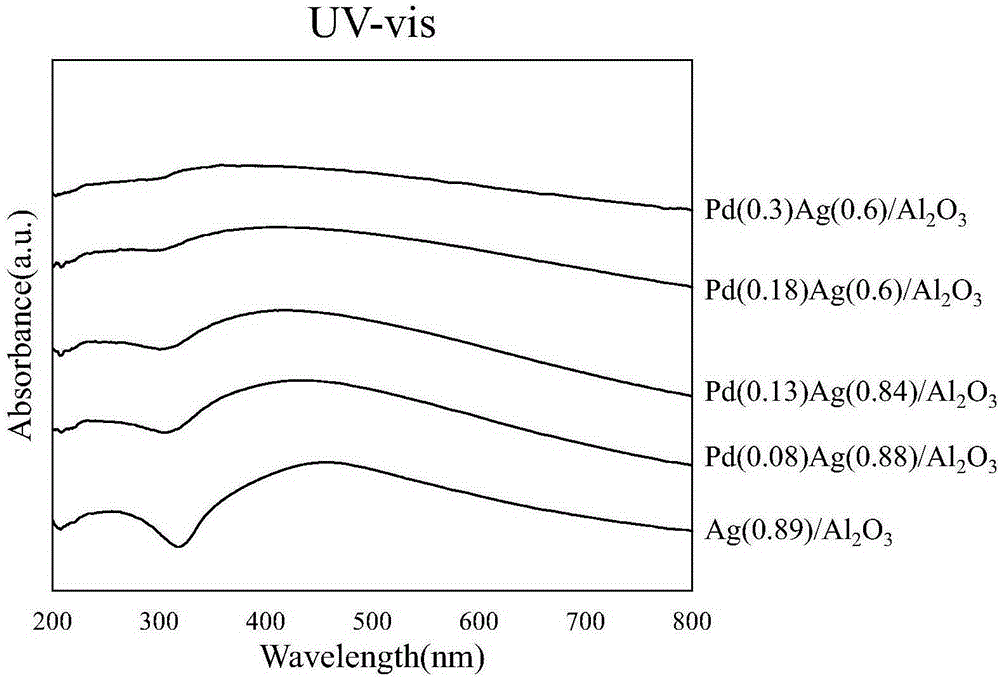

[0034] Ag-Pd / γ-Al 2 o 3 Catalyst Preparation: Preparation of Ag-Pd / γ-Al by Impregnation-Displacement Method 2 o 3 Catalyst, its specific steps are as follows: a certain quality of γ-Al 2 o 3 Added to a certain amount of AgNO 3 In the solution, after dipping and stirring for 2 hours, the solution was evaporated to dryness in a water bath at 90°C, dried at 105°C, and roasted in a muffle furnace at 300°C for 4 hours for later use. Ag / γ-Al prepared by impregnation method 2 o 3 Reduction was performed at 300 °C for 2 h under a hydrogen atmosphere, and then transferred to an inert gas atmosphere. In an inert gas atmosphere, a certain amount of Ag / γ-Al 2 o 3Add oxygen-deionized deionized water, and while vigorously stirring, add a certain volume and concentration of deoxygenated Pd(NO 3 ) 2 Solution, after the dropwise addition, the resulting suspension was stirred for 1.5 hours, then the suspension was filtered and washe...

Embodiment 21

[0038] Embodiment 21,2-dichloroethane selective hydrodechlorination reaction

[0039] According to the method of Example 1, the Ag-Pd / γ-Al prepared by impregnation-replacement method 2 o 3 The catalyst, wherein, after the replacement reaction loads Pd, the actual loading amount of Ag is 0.88wt%, and the actual loading amount of Pd is 0.08wt%. The catalyst is used to catalyze the gas-phase selective hydrodechlorination reaction of 1,2-dichloroethane; the selective hydrodechlorination reaction process is an in-situ reaction process, and the catalyst is first 2 After the atmosphere is reduced at 300°C for 2 to 5 hours, the temperature is adjusted to the reaction temperature to carry out the hydrodechlorination reaction of 1,2-dichloroethane. The consumption of catalyst is 100mg, and reaction temperature is 250 ℃, H 2 The concentration of 1,2-dichloroethane is 30000-40000ppm, the concentration of 1,2-dichloroethane is 7000-7500ppm, He is used as carrier gas, hydrogen is used as...

Embodiment 31

[0040] Embodiment 31,2-dichloroethane selective hydrodechlorination reaction

[0041] According to the method for example 1, the Ag-Pd / γ-Al prepared by impregnation-replacement method 2 o 3 The catalyst, wherein, after the substitution reaction loads Pd, the actual loading amount of Ag is 0.6wt%, and the actual loading amount of Pd is 0.18wt%. The catalyst is used to catalyze the gas-phase selective hydrodechlorination reaction of 1,2-dichloroethane; the selective hydrodechlorination reaction process is an in-situ reaction process, and the catalyst is first 2 After the atmosphere is reduced at 300°C for 2 to 5 hours, the temperature is adjusted to the reaction temperature to carry out the hydrodechlorination reaction of 1,2-dichloroethane. The consumption of catalyst is 100mg, and reaction temperature is 250 ℃, H 2 The concentration of 1,2-dichloroethane is 30000-40000ppm, the concentration of 1,2-dichloroethane is 7000-7500ppm, He is used as carrier gas, hydrogen is used a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com