Beneficiation method for treating copper smelting slag

A technology of copper smelting slag and beneficiation method, applied in flotation, solid separation and other directions, can solve problems such as high recovery rate, and achieve the effects of high recovery rate, easy management and operation, and environmental protection of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

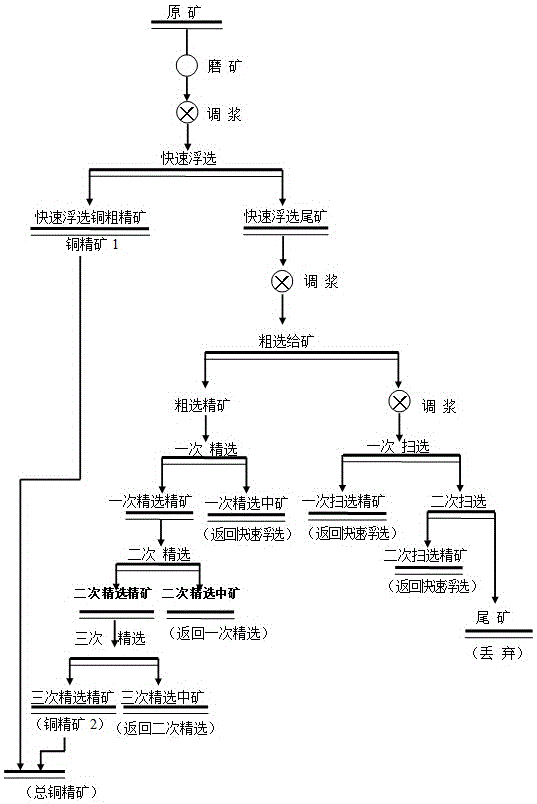

Image

Examples

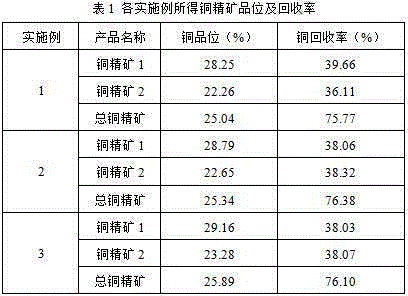

Embodiment 1

[0017] Flotation of a copper smelting slag, the copper grade of the copper smelting slag is 0.95%. The valuable elements of copper slag are copper, zinc, iron, etc. The carrier minerals of copper slag are mainly chalcopyrite, the zinc carrier minerals are mainly sphalerite, the iron carrier minerals are mainly magnetite, and a small amount of limonite. The chalcopyrite is more evenly distributed and has a finer particle size. The solid solution formed with the sphalerite is dispersed in the glass in the form of microbeads and is extremely difficult to dissociate. The beneficiation steps of copper minerals are:

[0018] 1) Fast flotation: Grind the copper smelting slag or raw ore to a fineness of less than 0.043 mm, accounting for 75%, adjust the slurry concentration to 38%, add copper mineral collecting foaming agent per ton of raw ore: n-butyl yellow Sodium ortho 15g / t, terpineol 7.5g / t, agitate, perform copper fast flotation flotation operation, obtain fast flotation copper co...

Embodiment 2

[0024] Example 2. The original ore is the same as Example 1. The beneficiation steps of copper minerals are:

[0025] 1) Fast flotation: Grind the copper smelting slag or raw ore to a fineness of less than 0.043 mm, accounting for 80%, adjust the slurry concentration to 34%, add copper mineral collecting foaming agent per ton of raw ore: n-butyl yellow Sodium ortho 10g / t, terpineol 10g / t, stirring, perform copper fast flotation flotation operation, obtain fast flotation copper coarse concentrate, namely copper concentrate 1, copper fast flotation tailings are used as copper roughing mine.

[0026] 2) Rough separation: add copper mineral combination collector foaming agent to copper rapid flotation tailings slurry per ton of raw ore: sodium n-butyl xanthate 15g / t, dibutyl ammonium dithiophosphate 20g / t, 20g / t of cyanoethyl diethylaminodithioformate, 15g / t of terpineol oil, stirring, carry out copper rough flotation operation, obtain rough concentrate as selected feed, and copper r...

Embodiment 3

[0031] Example 3. The original ore is the same as that in Example 1. The beneficiation steps of copper minerals are:

[0032] 1) Fast flotation: Grind the copper smelting slag or raw ore to a fineness of less than 0.043 mm, accounting for 85%, adjust the slurry concentration to 30%, add copper mineral collecting foaming agent per ton of raw ore: n-butyl yellow Sodium ortho 13g / t, terpineol oil 5g / t, stirring, perform copper fast flotation flotation operation, obtain fast flotation copper concentrate, namely copper concentrate 1, copper fast flotation tailings are used as copper rough mine.

[0033] 2) Rough separation: add copper mineral combination collector foaming agent to copper rapid flotation tailings slurry per ton of raw ore: sodium n-butyl xanthate 25g / t, dibutyl ammonium dithiophosphate 15g / t, 15g / t of cyanoethyl diethylaminodithioformate, 5g / t of terpineol oil, stirring, and carrying out the flotation operation of copper roughing, obtaining the roughing concentrate as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com