A kind of liquid cement grinding aid for vertical mill

A cement grinding aid and liquid technology, which is applied in the field of cement manufacturing, can solve the problems of poor adaptability between cement products and concrete admixtures, unsatisfactory particle distribution and particle gradation, and large water consumption for standard consistency of cement products. Consistency water consumption, cement strength improvement, and the effect of improving particle gradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

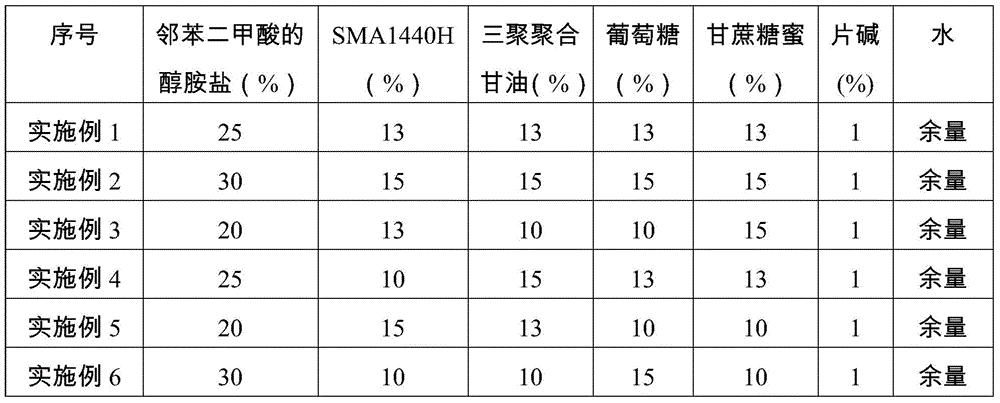

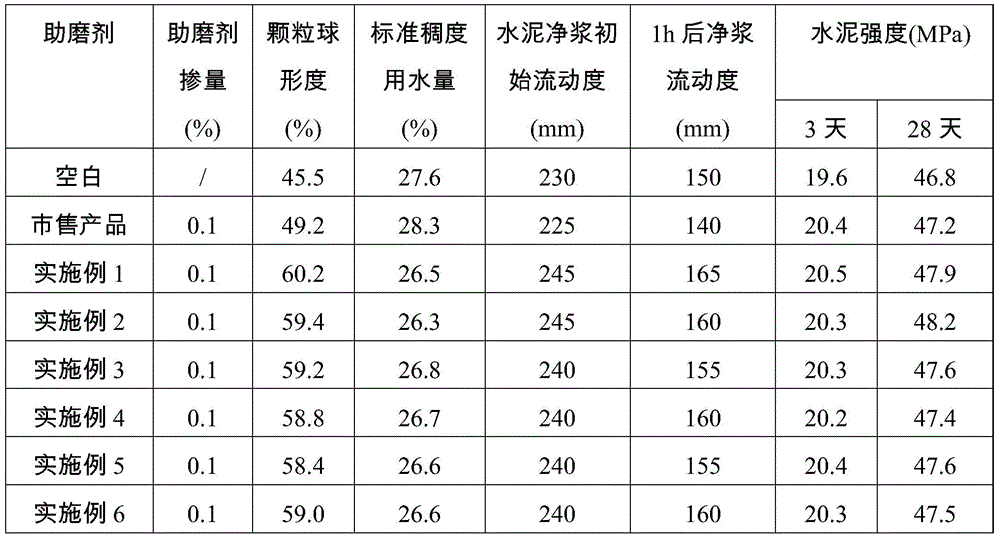

[0012] The present invention will be further described below in conjunction with embodiment.

[0013] The percentages mentioned in the present invention are all mass percentages.

[0014] 1) Cement mix ratio: clinker 75%, desulfurized gypsum 5%, limestone 10%, fly ash 10%.

[0015] 2) Raw materials:

[0016] Clinker: Produced by Conch Cement Group China Cement Plant, 3-day strength 31.2MPa, 28-day strength 58.6MPa;

[0017] Desulfurization gypsum: produced by Nanjing Yifu Building Materials Industry Co., Ltd.;

[0018] Limestone: Zhenjiang Baohua United Quarry, 5-10mm crushed stone;

[0019] Fly ash: Raw ash produced by Nanjing Jiangsu Nanre Power Generation Co., Ltd.

[0020] Alcoholamine salt of phthalic acid, concentration 50%, produced by Nanjing Shenhe New Material Technology Co., Ltd.;

[0021] Styrene maleic anhydride copolymer, model SMA1440H, concentration 33.5%, clear liquid, produced by Guangzhou Runao Chemical Materials Co., Ltd.;

[0022] Tripolymerized glyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com