A treatment process and application of phosphate mineral acid method ore dressing and acid liquid produced in the beneficiation process

A treatment process and technology for phosphate rock, applied in the field of phosphate compound fertilizer, can solve the problem of acid hydrolysis purification liquid difficult to handle, and achieve the effect of reducing the amount of sulfuric acid used, good synergy and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A kind of treatment process of the acid solution produced in the ore beneficiation by phosphoric rock acid method and the ore beneficiation process, it comprises the following steps:

[0019] 1) Put the phosphate rock into the crusher for crushing, send it to the ball mill after coarse crushing, and grind it to a particle size of 100 mesh ore powder, wherein additives are added to the ball mill, and the amount of the additive added is the mass of the phosphate rock one-thousandth of;

[0020] 2) The mineral powder obtained in step 1) is transported to the purification reactor through the conveying equipment, firstly add the mixed bacterial solution, stir evenly, let it stand for 48 hours, then add 98% sulfuric acid, stir and react at 100 rpm for 12 hours, and then send to filter Machine, filtered to obtain solid materials and liquid materials, the solid materials are purified qualified phosphate rock, sent to the phosphoric acid workshop; the amount of mixed bacteria li...

Embodiment 2

[0028] The fertilizer effect test of the compound fertilizer that embodiment 1 prepares:

[0029] 1. Effect fertilizer experiment for planting sorghum:

[0030] Control group: compound fertilizer: containing 35% urea, 35% monoammonium phosphate, 30% potassium chloride;

[0031] Test group: the compound fertilizer that embodiment 1 prepares;

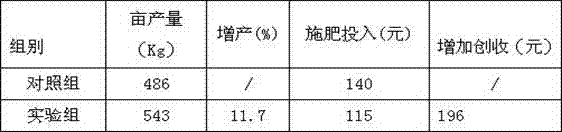

[0032] The soil quality and planting conditions of the experimental field are exactly the same, the area of the control group and the experimental group are both 10 mu; the amount of fertilizer applied is 50kg / mu; the specific test results are shown in Table 1:

[0033] Table 1

[0034]

[0035] Note: the compound fertilizer is calculated at 2.8 yuan / kg, the organic fertilizer of the present invention is calculated at 2.3 yuan / kg, and the sorghum is calculated at 3.0 yuan / kg.

[0036] 2. Planting sweet potato fertilizer effect experiment:

[0037] Set up two treatment test fields, both with an area of 10 mu, which are the contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com