Intumescent flame retardant modified montmorillonite and preparation method thereof

An intumescent flame retardant and montmorillonite technology, applied in the field of flame retardants, can solve the problems of difficulty in uniform dispersion and affect the synergistic flame retardant effect, so as to reduce secondary hazards, improve compatibility, and improve lipophilicity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

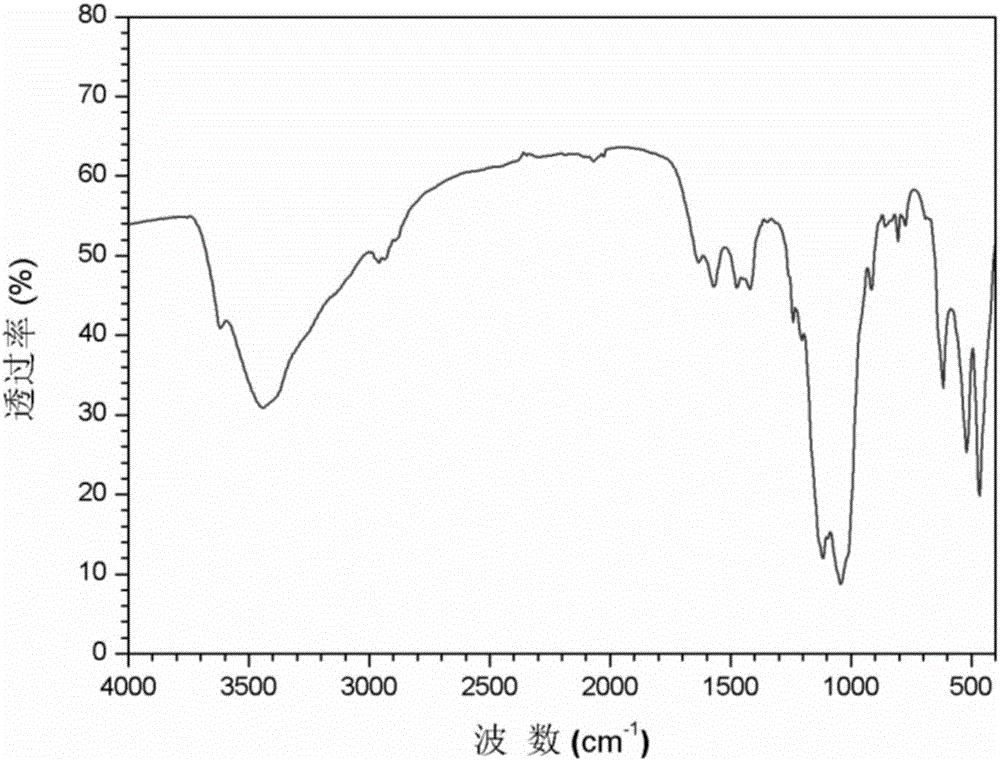

Image

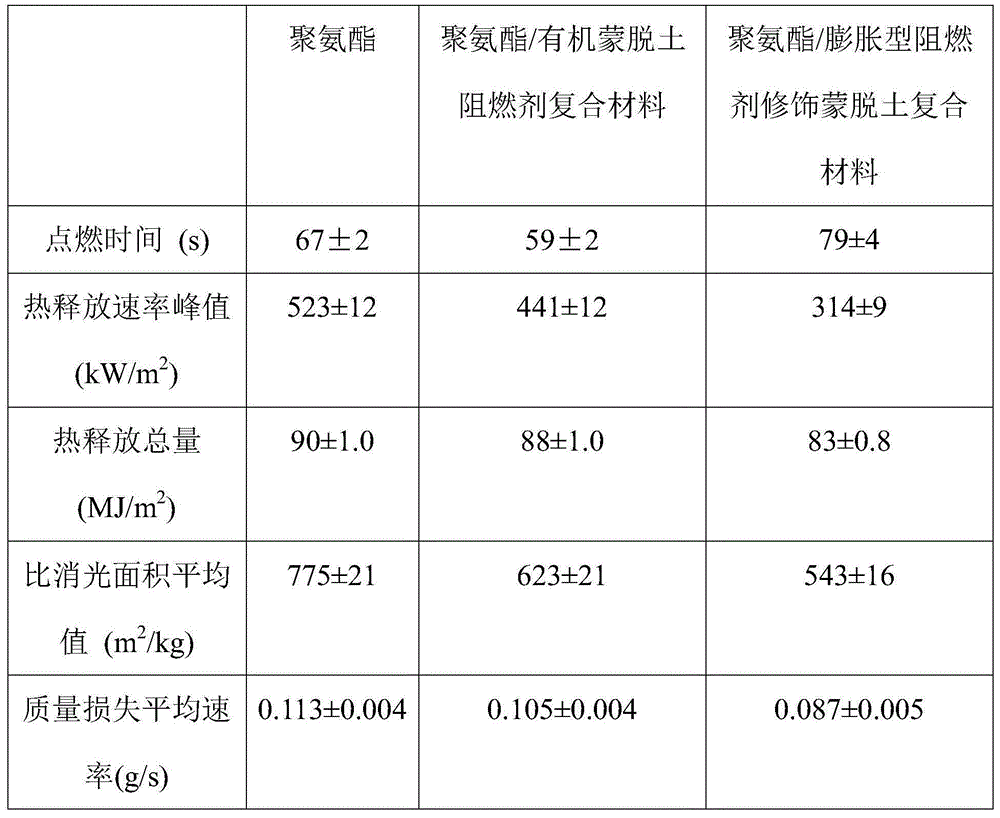

Examples

Embodiment 1

[0020] Add 8g of montmorillonite to 150mL of toluene, ultrasonically disperse it for 30 minutes, transfer it to a dry four-neck flask equipped with a mechanical stirrer, a thermometer, a reflux condenser and a dropping funnel, and drop 0.753g of N-aminoethyl - Gamma-aminopropyltrimethoxysilane and 15mL toluene mixed solution, raised to reflux temperature, continued to stir for 6 hours, then cooled to 45°C, added dropwise 1.247g 2-oxo-2-chloro-5,5- The mixed solution of dimethyl-1,3,2-dioxaphosphorinane, 3.6 g of triethylamine and 15 mL of toluene was continued to react for 6 hours. Then the suspension obtained by the reaction was filtered, washed repeatedly with methanol, and dried in an oven at 80° C. for 24 hours to obtain an intumescent flame retardant modified montmorillonite, wherein the mass content of the intumescent flame retardant was 20%.

Embodiment 2

[0022] Add 6.467g of montmorillonite to 100mL of toluene, ultrasonically disperse for 30 minutes, then transfer it to a dry four-necked flask equipped with a mechanical stirrer, a thermometer, a reflux condenser and a dropping funnel, and add 0.0753g of N-aminoethyl ether dropwise at room temperature Base-γ-aminopropyltrimethoxysilane and 10mL of toluene mixed solution, and raised to reflux temperature, continued stirring reaction for 6 hours, cooled to 50 ° C, dropwise added 0.1247g 2-oxo-2-chloro-5,5- The mixed solution of dimethyl-1,3,2-dioxaphosphorinane, 0.5 g of triethylamine and 10 mL of toluene was continued to react for 4 hours. Then the suspension obtained by the reaction was filtered, washed repeatedly with methanol, and dried in an oven at 80° C. for 24 hours to obtain an intumescent flame retardant modified montmorillonite, wherein the mass content of the intumescent flame retardant was 3%.

Embodiment 3

[0024] Add 6g of montmorillonite to 80mL of toluene, ultrasonically disperse it for 30 minutes, then transfer it to a dry four-necked flask equipped with a mechanical stirrer, a thermometer, a reflux condenser and a dropping funnel, and add 2.188g of N-aminoethyl - Mixed solution of γ-aminopropyltrimethoxysilane and 20mL toluene, raised to reflux temperature, continued to stir for 6 hours, cooled to 30°C, added dropwise 2.812g of 2-oxo-2-chloro-5,5-di The mixed solution of methyl-1,3,2-dioxaphosphorinane, 5.4 g of triethylamine and 30 mL of toluene was continued to react for 5 hours. Then the suspension obtained by the reaction was filtered, washed repeatedly with methanol, and dried in an oven at 80° C. for 24 hours to obtain an intumescent flame retardant modified montmorillonite, wherein the mass content of the intumescent flame retardant was 40%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com