Inhibitor for inhibiting high-sulfur coal from spontaneous combustion

An inhibitor, high-sulfur coal technology, applied in safety devices, mining equipment, earthwork drilling, etc. It has the effect of suppressing temperature rise and ensuring wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The inhibitor of the high-sulfur coal spontaneous combustion of the present embodiment, its composition is by mass percentage: MgCl 2 15%, ZnCl 2 3%, NH 4 Cl0.2%, sodium lauryl sulfate 0.5%, sodium tetraborate 0.3%, and the balance is solvent water.

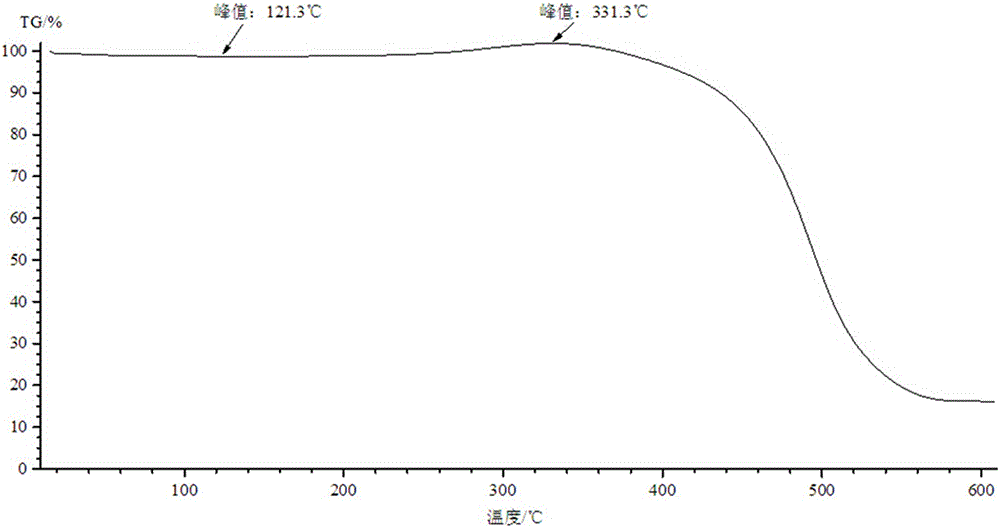

[0019] According to the TG curve of the coal sample under the condition of temperature programming, the inhibitory effect of the inhibitor is analyzed, and the specific process is as follows:

[0020] Firstly, the raw coal sample was pulverized with a ball mill, and then the raw coal sample with a particle size of 0.150 mm was sieved by a sampling sieve as the experimental raw coal sample, and put into a grinding bottle for later use.

[0021] Weigh 1000mg of raw coal sample, measure 1ml of the prepared inhibitor solution, fully mix the raw coal sample with the inhibitor, place in a cool, ventilated place, and after standing for 7 days, carry out thermogravimetric analysis. The experimental heating rate is 5 ℃ / min, reac...

Embodiment 2

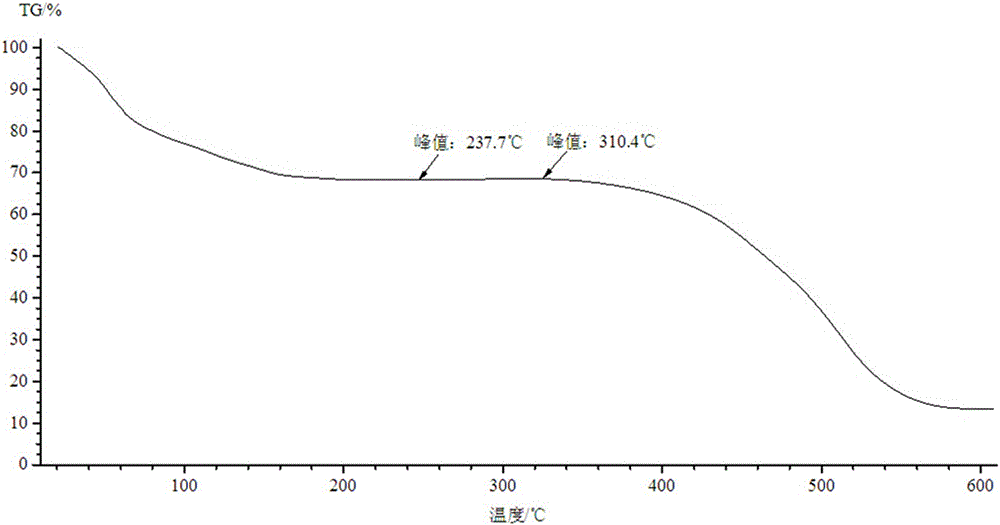

[0027] The inhibitor of the high-sulfur coal spontaneous combustion of the present embodiment, its composition is by mass percentage: MgCl 2 16%, ZnCl 2 5%, NH 4 Cl 0.1%, sodium lauryl sulfate 0.8%, sodium tetraborate 0.4%, and the balance is solvent water.

[0028] Through the same thermogravimetric analysis experiment process, the oxidative spontaneous combustion dehydration stage of the raw coal sample soaked by the inhibitor of this embodiment was delayed from 121.3°C to 238.1°C, while the activation energy of the oxidative spontaneous combustion weight gain stage was changed from 112.20kJ / mol Increased to 262.70kJ / mol, effectively preventing the spontaneous combustion of high-sulfur coal.

Embodiment 3

[0030] The inhibitor of the high-sulfur coal spontaneous combustion of the present embodiment, its composition is by mass percentage: MgCl 2 17%, ZnCl 2 2%, NH 4 Cl0.15%, sodium lauryl sulfate 1%, sodium tetraborate 0.5%, and the balance is solvent water.

[0031] Through the same thermogravimetric analysis experiment process, the oxidative spontaneous combustion dehydration stage of the raw coal sample soaked by the inhibitor of this example was delayed from 121.3°C to 237.8°C, while the activation energy of the oxidative spontaneous combustion weight gain stage was changed from 112.20kJ / mol Increased to 259.56kJ / mol, effectively preventing the spontaneous combustion of high-sulfur coal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com