Device and method for measuring uniformity of refractive index of large aperture uniaxial crystal

A uniaxial crystal and measuring device technology, applied in the optical field, can solve the problems of inability to realize orthogonal polarization state switching, inability to realize uniformity measurement, inability to deduct errors, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

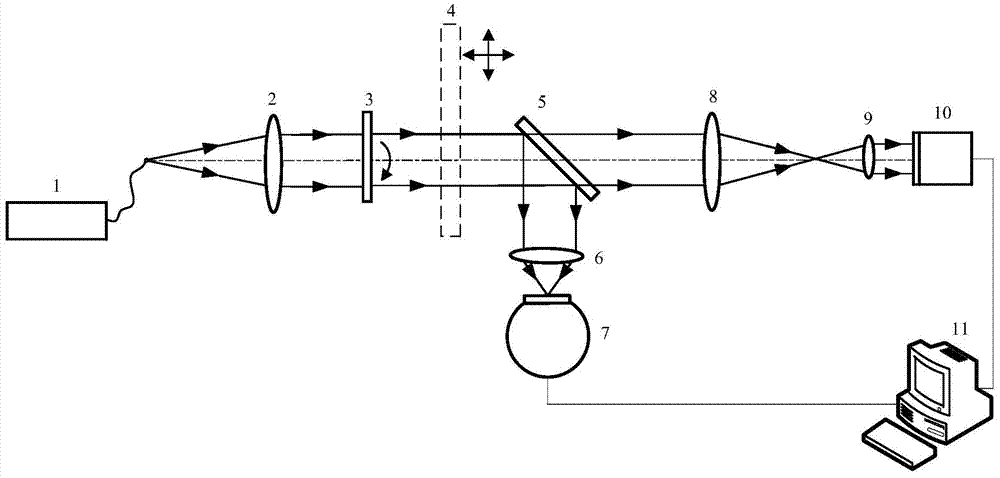

[0035] Such as figure 1 As shown, the present invention provides a large-aperture uniaxial crystal refractive index uniformity measuring device, the device consists of a laser 1, a collimating mirror 2, a polarizer 3, a large-aperture uniaxial crystal 4 to be measured, a transflective Mirror 5, converging mirror 6, integrating sphere power meter 7, beam reduction system objective lens 8, beam reduction system eyepiece 9, Shack-Hartmann wavefront sensor 10 and computer 11. The collimator, polarizer and half-mirror are sequentially arranged on the optical path where the output light of the laser is located; the half-mirror reflects and transmits the light incident on the half-mirror and forms reflected light and transmitted light respectively. light; the converging mirror is set on the optical path of the reflected light and converges the reflected light into the integrating sphere power meter; the objective lens of the beam reduction system, the eyepiece of the beam reduction s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com