Neutron irradiation protective clothing material and preparation method for same

A radiation protection and neutron technology, used in reactors, nuclear engineering, shielding, etc., can solve the problems of low density of rubber hydrogen atoms, inability to achieve effective neutron field protection, and neutron moderation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

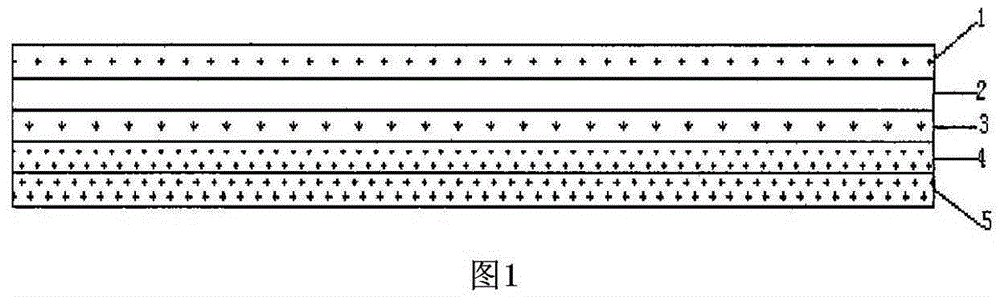

[0021] Embodiment 1: see attached figure 1 , a neutron radiation protective clothing material, characterized in that it includes at least five layers of non-woven fabrics with different functional fillers, the outermost layer 1 is a non-woven fabric containing heavy metal fillers, which is used to rapidly reduce the neutron energy to inelastic scattering Threshold, while shielding X, gamma rays; the second layer 2 is non-woven fabric without fillers, used to further moderate neutrons; the third layer 3 is non-woven fabrics with low boron-containing fillers, used to reduce neutron energy, Simultaneously absorb thermal neutrons; the fourth layer 4 is a high boron-containing filler non-woven fabric for further absorbing thermal neutrons; the innermost layer 5 is a lead-containing filler non-woven fabric for shielding gamma rays;

Embodiment 2

[0022] Embodiment 2: see attached figure 1 , The neutron radiation protection clothing material as described in Example 1 is characterized in that the composition and mass ratio of the outermost layer 1 non-woven fabric containing heavy metal fillers are: 60% to 85% of heavy metal compounds, 1% of adhesive ~ 3%, antioxidant 0.3% ~ 0.7%, filament-forming polymer 11.3% ~ 38.7%; the composition and mass ratio of the second layer 2 non-woven fabric without fillers are: antioxidant 0.3% ~ 0.7%, composition Silk polymer 99.3% to 99.7%; the composition and mass ratio of the third layer 3 low boron-containing filler non-woven fabric are: boron compound 5% to 30%, adhesive 1% to 3%, antioxidant 0.3% to 0.7%, filament-forming polymer 66.3%-93.7%; the composition and mass ratio of the fourth layer 4 high boron-containing filler non-woven fabric are: boron compound 50%-70%, adhesive 1%-3%, anti-oxidation 0.3% to 0.7% of the agent, 26.3% to 48.7% of the filament-forming polymer; the compo...

Embodiment 3

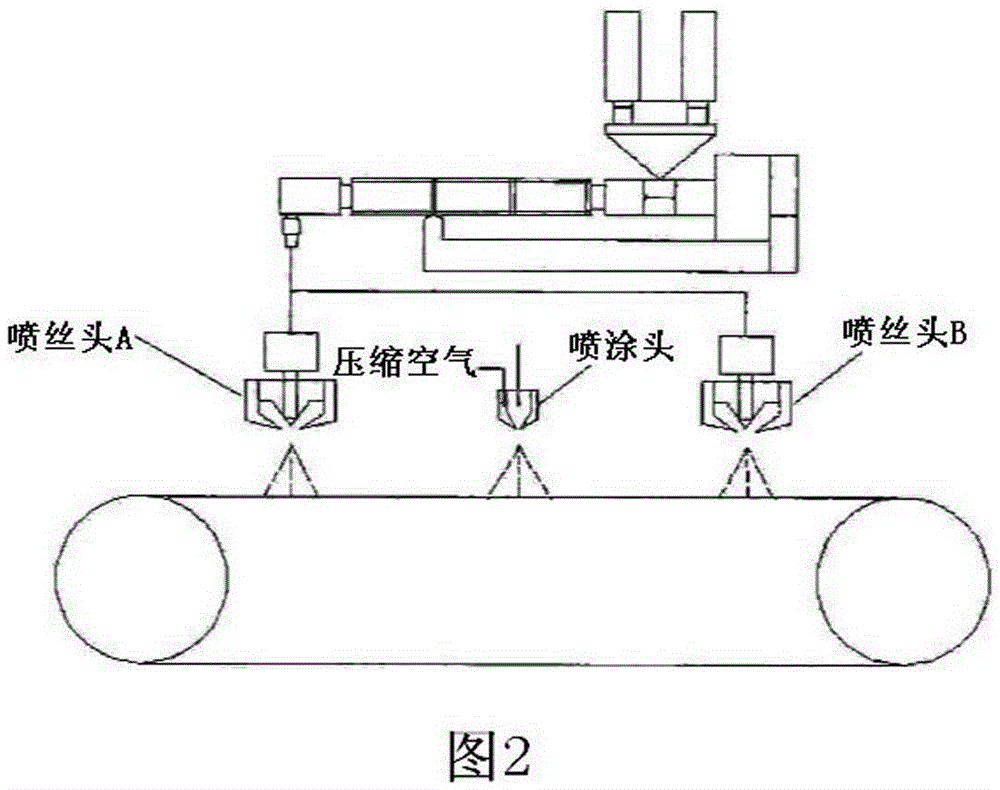

[0026] Embodiment 3: see attached figure 2 , the preparation method of each functional layer of neutron radiation protection clothing material as described in embodiment 1 or 2, its production process is:

[0027] (a) Melt-blown: After the filament-forming polymer chips and antioxidant are mixed evenly, they are fed into the screw extruder to be heated and melted, and extruded from melt-blown spinneret A and melt-blown spinneret B through melt-blown spinning to form Fiber web;

[0028] (b) Spraying: Stir the functional filler and adhesive in the stirring tank for 20 to 30 minutes to mix evenly, add it to the barrel of the spraying device, spray it from the spraying head through the spraying process, and adjust the functional filler by adjusting the reciprocating speed of the spraying gun content;

[0029] (c) Composite: The fiber web ejected from the melt-blown spinneret A, the functional filler sprayed by the spray head, and the fiber web ejected from the melt-blown spinne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com