Nylon latent-crimp yarn having outstanding elasticity and cool feel

A crimping, nylon technology that is used in filament/thread forming, conjugated synthetic polymer rayon, fiber processing, etc., to solve spinning performance and yarn productivity reduction, yarn bending spinning speed, It is difficult to produce on a commercial scale and other problems, to achieve the effects of high productivity, high moisture regain, and good cooling sensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

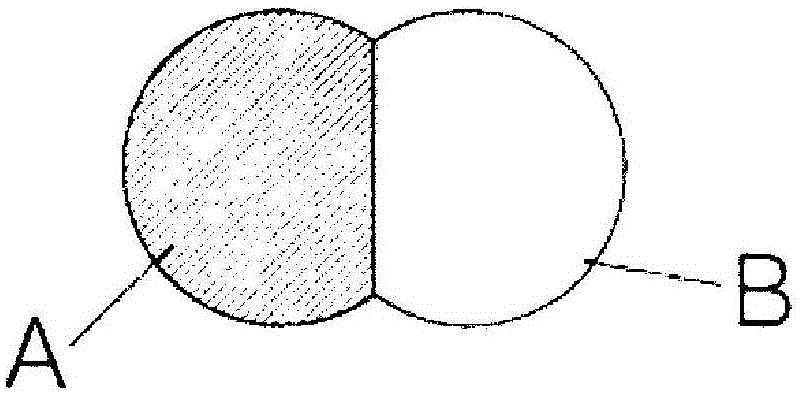

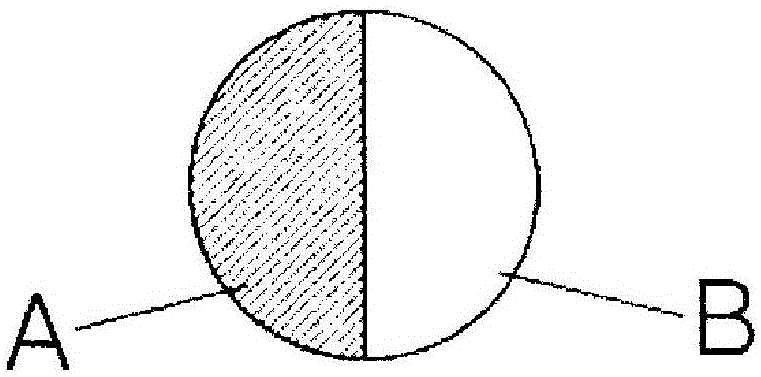

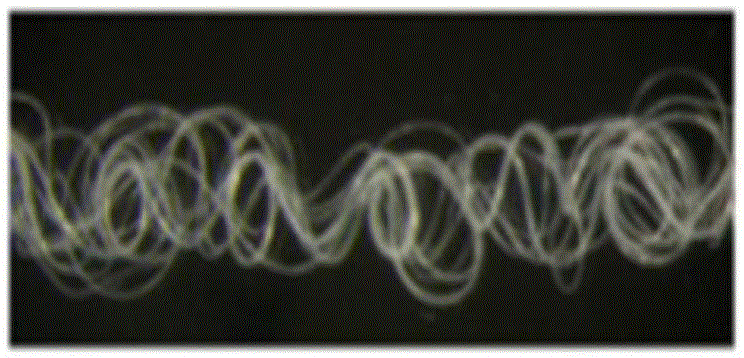

[0042] Obtain 30mol% pyrrolidone and 70mol% caprolactam by carrying out anionic polymerization reaction, and under the spinning temperature of 260 ℃, the nylon 64 random copolymer that melting point is 170 ℃ and relative viscosity (RV) is 2.6 and relative viscosity ( Nylon 6 with an RV) of 2.6 was extruded with an extruder by a side-by-side composite spinning method. After spinning in the spinning pack in a 50:50 weight ratio, it is cooled and solidified in a cooling chamber. Winding was performed at a speed of 3000 m / min by a first guide roll and a second guide roll to prepare a half-drawn yarn of 85-denier / 24 filaments.

[0043] Utilize draw-winding machine, the above-mentioned semi-drawn yarn of winding is stretched with the spinning speed of 500m / min and the drawing ratio of 1.26, and winding 70-denier / 24 long filaments (70-denier / 24filament) specification drawing yarn to prepare nylon latent crimping yarn.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com