Solvent thermal method for preparing copper nanowire

A solvothermal method and copper nanowire technology, which is applied in the field of metal nanowire preparation, can solve the problems that copper nanowires have not been seen in literature and patent public reports, and achieve the effects of low cost, simple operation, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Mix copper formate tetrahydrate (9.04g, 0.04mol) and n-octylamine (10.32g, 0.08mol), and stir mechanically at 35°C and 100 rpm for 1h to obtain copper formate-n-octylamine complex Material 19.36g;

[0030] (2) Add oleylamine (5.35g, 0.02mol) and oleic acid (1.41g, 0.005mol) to the copper formate-n-octylamine complex (19.36g, 0.04mol) obtained in step (1), and add paraffin (12g), at 75 DEG C, stirring continuously for 1 hour at a stirring speed of 100 rpm to obtain a reaction mixture;

[0031] (3) Inject 38.12 g of the reaction mixture obtained in step (2) into a 50 ml three-necked distillation flask, and heat the reaction at 110° C. for 1 h under nitrogen protection. After the distillation flask is naturally cooled to room temperature, add n-hexane (480 mL ), after ultrasonic dispersion for 5 minutes, centrifuge at a centrifugal rate of 12,000 rpm for 10 minutes, and dry to obtain 2.56 g of copper nanowires.

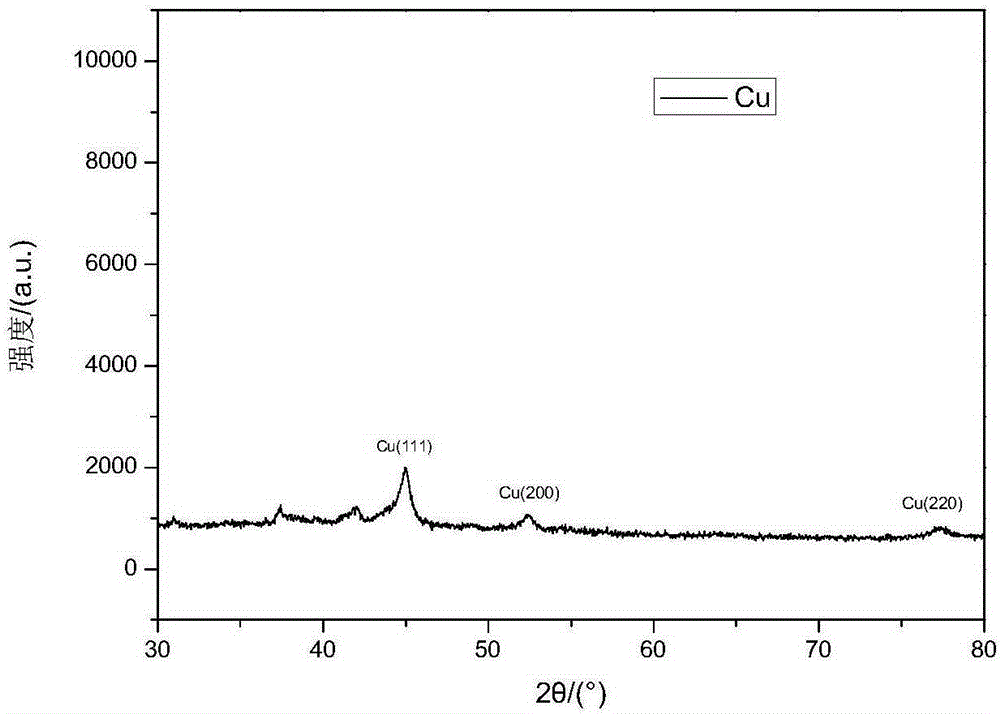

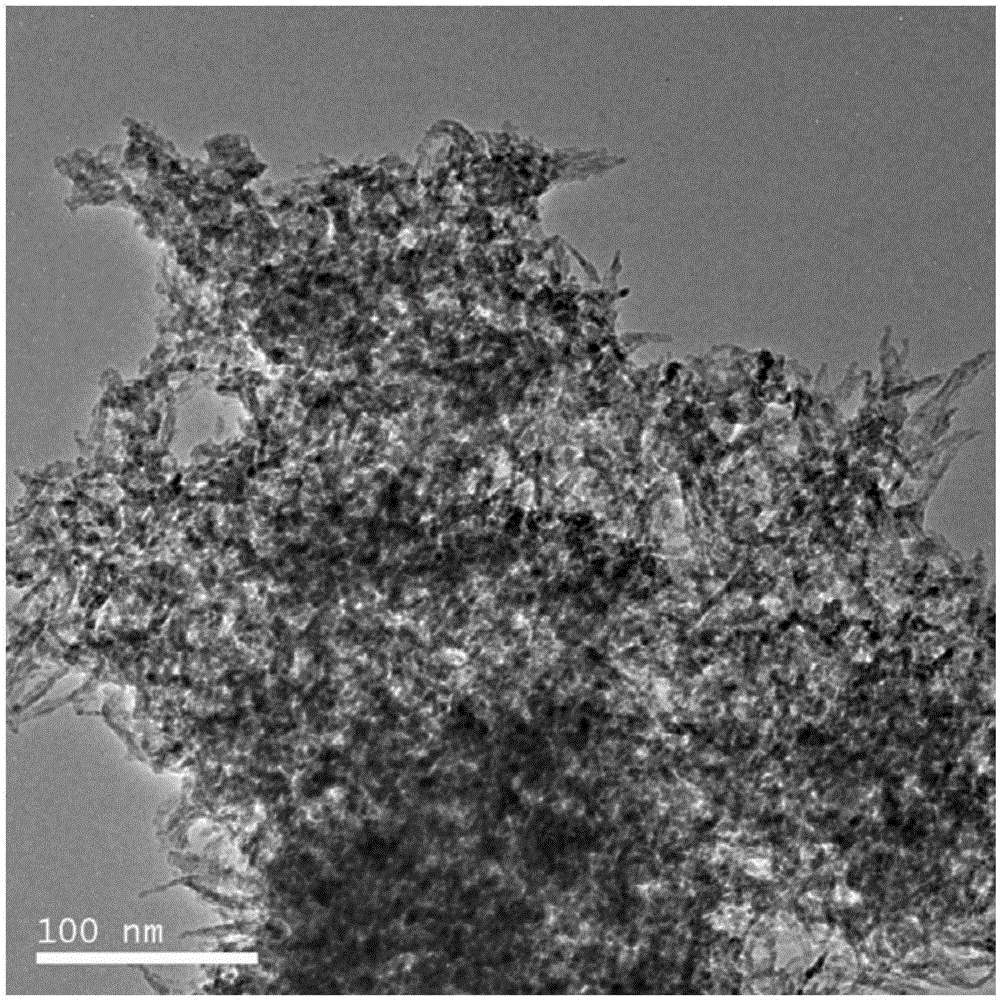

[0032] figure 2 It is the transmission electron micr...

Embodiment 2

[0034] (1) Mix copper formate tetrahydrate (4.52g, 0.02mol) and n-octylamine (5.16g, 0.04mol), and stir mechanically at 35°C and 140 rpm for 1h to obtain copper formate-n-octylamine complex Material 9.68g;

[0035] (2) Add oleylamine (5.35g, 0.02mol) and oleic acid (1.41g, 0.005mol) to the copper formate-n-octylamine complex (9.68g, 0.01mol) obtained in step (1), and add paraffin (12g), at 75 DEG C, stirring continuously for 1 hour at a stirring speed of 100 rpm to obtain a reaction mixture;

[0036] (3) Inject 28.44 g of the reaction mixture obtained in step (2) into a 50 ml three-necked distillation flask. Under nitrogen protection, heat the reaction at 150° C. for 1 h. After the distillation flask is naturally cooled to room temperature, add n-hexane (480 mL ), after ultrasonic dispersion for 5 minutes, centrifuge at a centrifugal rate of 12,000 rpm for 10 minutes, and dry to obtain 1.28 g of copper nanowires.

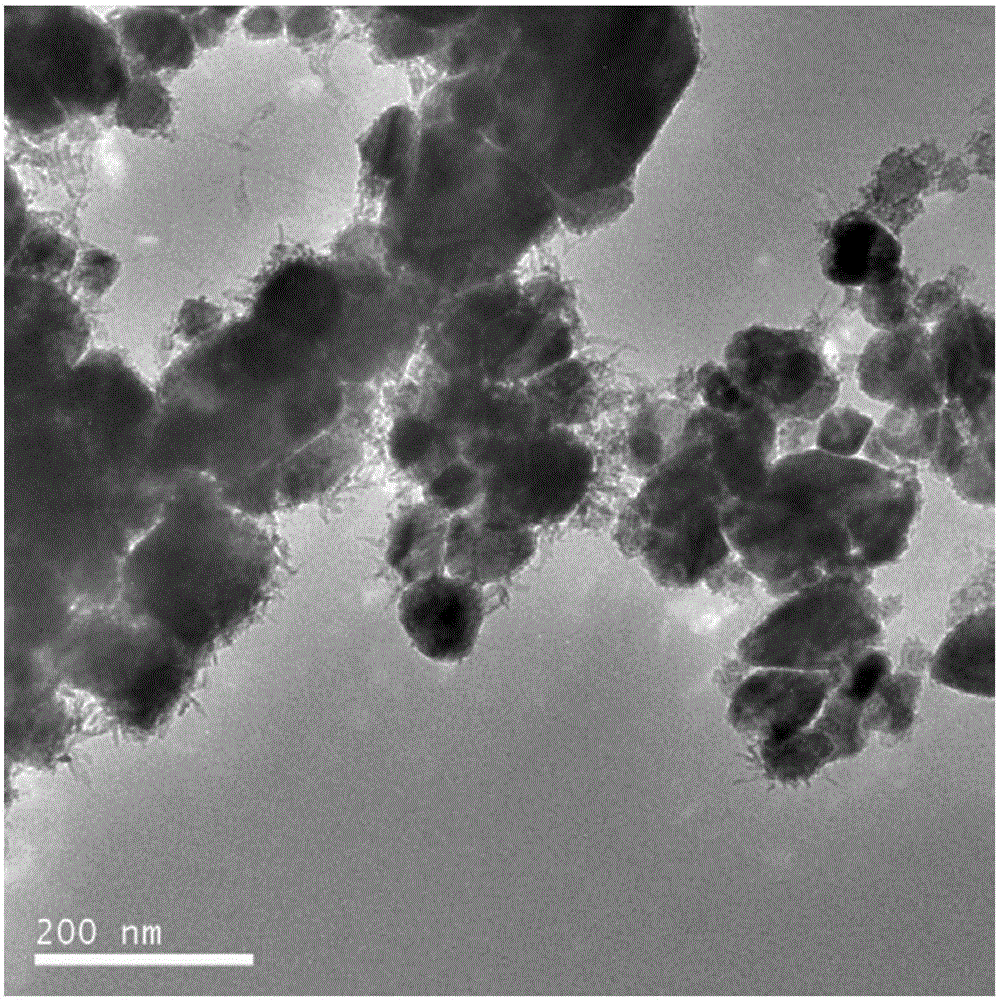

[0037] image 3 It is a transmission electron microscope ph...

Embodiment 3

[0039] (1) Mix copper formate tetrahydrate (4.52g, 0.02mol) and n-octylamine (5.16g, 0.04mol), and stir mechanically at 35°C and 140 rpm for 1h to obtain copper formate-n-octylamine complex Material 9.68g;

[0040](2) Add oleylamine (5.35g, 0.02mol) and oleic acid (1.41g, 0.005mol) to the copper formate-n-octylamine complex (9.68g, 0.01mol) obtained in step (1), and add paraffin (12g), at 75 DEG C, stirring continuously for 1 hour at a stirring speed of 100 rpm to obtain a reaction mixture;

[0041] (3) 28.44 g of the reaction mixture obtained in step (2) is injected into a 50 ml three-necked distillation flask, under nitrogen protection, the reaction was heated at 150° C. for 30 minutes, and the distillation flask was naturally cooled to room temperature, and normal hexane ( 480 mL), after ultrasonic dispersion for 5 min, centrifuge at a centrifugal rate of 12000 rpm for 10 min, and dry to obtain 1.28 g of the product copper nanowire.

[0042] Figure 4 It is the transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com