Friction-stir welding device and method for motor rotor

A motor rotor and friction stir technology, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of high cost of automation special equipment, overcome the bottleneck of surface treatment, improve electrical conductivity and quality, and reduce defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

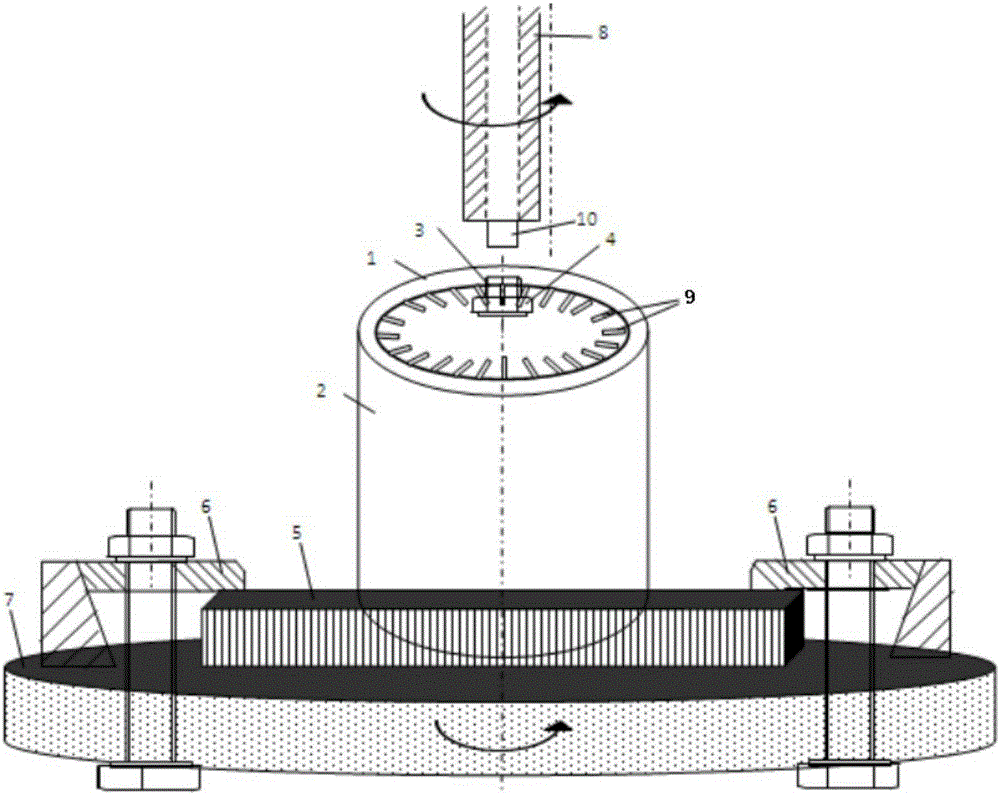

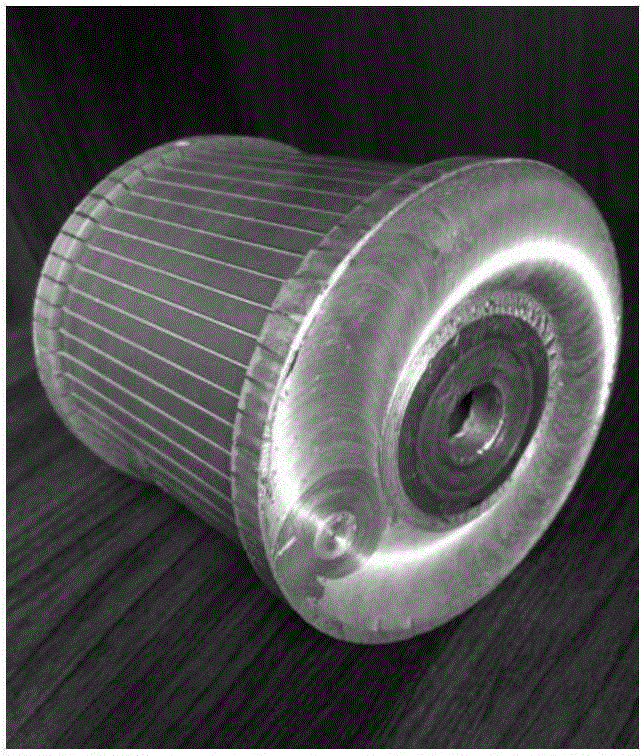

[0031] Refer to attached figure 1 , the present embodiment provides a friction stir welding device for a motor rotor, which includes 1. an end face of the motor rotor to be welded, 2. a sleeve, 3. a screw, 4. a nut, 5. a fixing plate, 6. a pressing plate, 7. .Turntable, 8. Stirring head, 9. Guide bar, 10. Stirring needle.

[0032] Specifically include the following steps:

[0033] 1. Tooling preparation and clamping: The outer diameter of one end face 1 of the motor rotor to be welded is Φ99.913mm, the height is 150.00mm, the inner diameter of the sleeve 2 is Φ100.052mm, and the height is 150.50mm. First, the sleeve 2 and the motor rotor to be welded are installed on the fixed plate 5 through the screw rod 3 and the nuts 4 at both ends thereof, and the fixed plate 5 can be fixed on a horizontally rotatable turntable 7 by a pressing plate 6 . The center of circle of the motor rotor to be welded coincides with the center of circle of the turntable 7 .

[0034] 2. Welding: fir...

Embodiment 2

[0042] With reference to Example 1, wherein the rotational speed of the stirring head is 1500rpm, the speed at which the stirring needle is inserted into the end face of the motor rotor to be welded is 50mm / min, the depression of the shoulder is 0.1mm, and the residence time is 10s. The rotational speed of the turntable is 200° / min, the retraction process is completed in a 50° journey. All the other are identical with embodiment 1.

Embodiment 3

[0044] With reference to Example 1, wherein the rotational speed of the stirring head is 500rpm, the speed at which the stirring needle is inserted into the end face of the motor rotor to be welded is 15mm / min, the depression of the shoulder is 0.3mm, the residence time is 30s, and the rotational speed of the turntable is 100° / min, the retraction process is completed in a 80° journey. All the other are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com