Self-healing material and preparation process thereof

A self-healing material and self-healing technology, applied in sol preparation, microsphere preparation, chemical instruments and methods, etc., can solve the problem of destroying the arrangement and design of hollow fibers, no commercialization, and no cheap mass production of microcapsules, etc. problem, to achieve the effect of simple and effective preparation and use, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0082] During the preparation of self-healing concrete, any suitable amount of surfactant can be added. Suitable surfactants include all commercially available surfactants for the preparation of concrete mixtures. Examples of surfactants used in concrete mixtures include chitosan, polyethyleneimine, polyethylene glycol bis(2-aminoethyl), poly(diallyl ammonium chloride), poly(2-methyl Acryloyloxyethyltrimethylammonium chloride-acrylamide) (poly(acrylamide / 2-methacyloxyehtytrimethylammoniumbromide)), poly(L-lysine hydrobromide) (poly(l-lysinehydrobromide)), poly (N-vinylpyrrolidone), poly(vinylamine) hydrochloride (poly(vinylamine)hydrochloride), poly(2-vinylpyridine, poly(2-vinylpyridine N-oxide)) (poly(2-vinylpyridineN -oxide)), poly(N-vinylpyrrolidone / 2-dimethylaminoethylmethacrylate) (poly(N-vinylpyrrolidone / 2-dimethylaminoethylmethacrylate)), poly(4-aminostyrene), poly(aniline) , poly(methylvinylnitrosamine) and poly(allylamine hydrochloride).

[0083] The present applic...

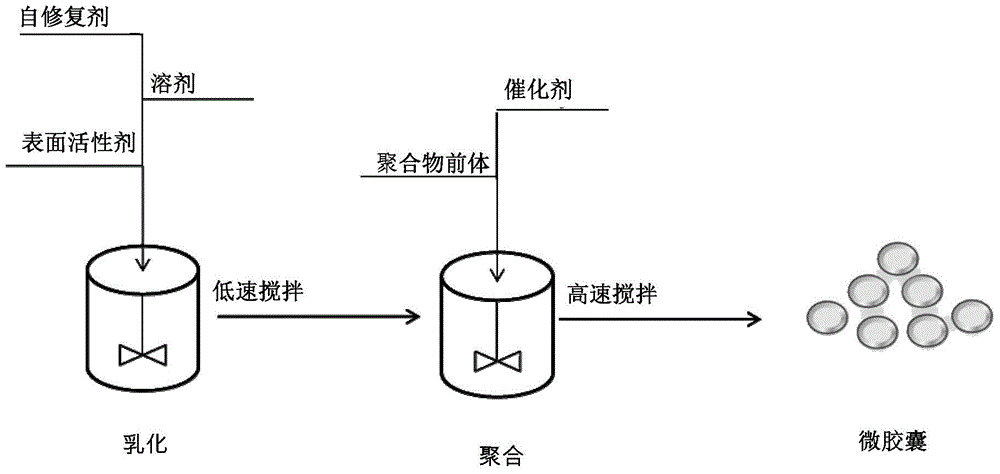

Embodiment 1

[0085] Microcapsules were prepared in a 100mL beaker, and at a stirring speed of 500rpm, 30mL of an aqueous colloidal silica solution was emulsified in an organic phase comprising toluene (64mL) and 5wt.% POEDO with 85 (Sorbitan Trioleate) Binary Mixture. After emulsifying for 10 minutes, add a solution containing an appropriate amount of monomer (15wt.% MDI) in toluene and two drops of catalyst DBTL for polymerization, and stir at a speed of 900 rpm for 160 minutes at 63°C to form a polymer cross-linked shell and encapsulate the silica nuclear material. The prepared microcapsules were further washed twice with toluene to remove residual MDI. The reagents used during emulsification and polymerization are summarized in Table 2 and Table 3.

[0086] Table 2 Reagents used for silica sol emulsification

[0087]

[0088] Table 3 Reagents used for silica sol polymerization

[0089]

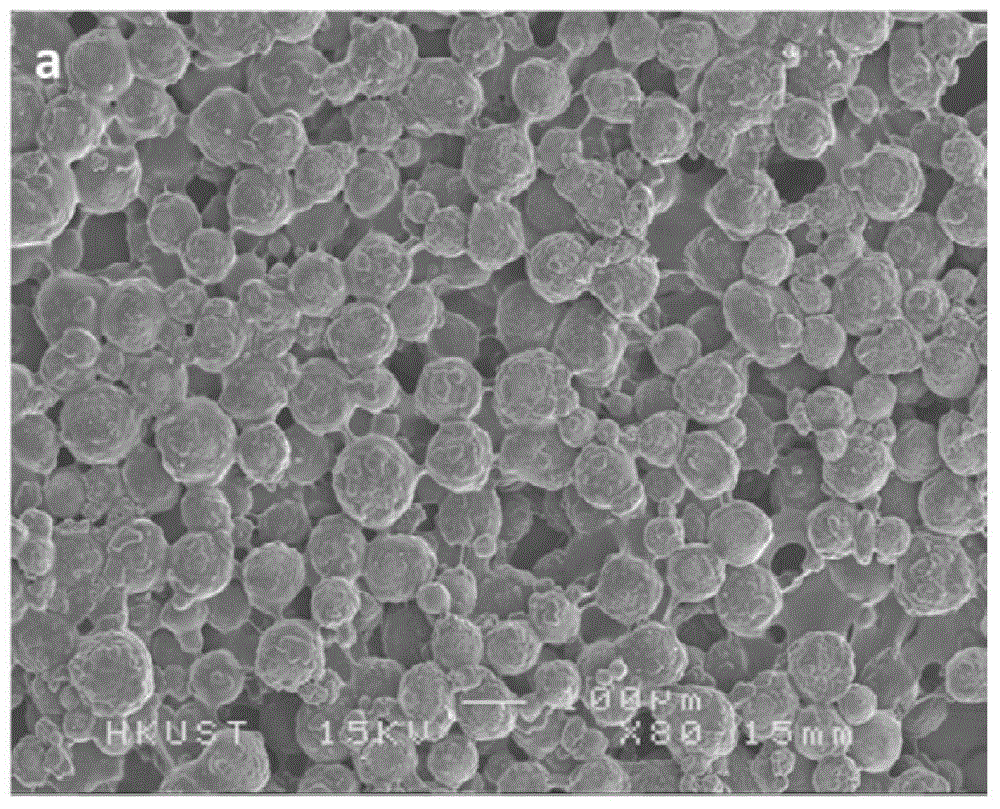

[0090] To investigate the morphology and properties of the microcapsules, the characteriz...

Embodiment 2

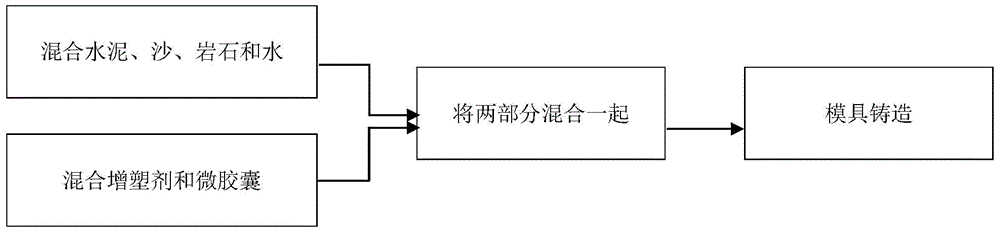

[0097] Twelve beams (30cmx10cmx4cm) were prepared with the composition ratio in Table 1 for the flexural strength test. A mixture of 7.84 kg of cement, 11.76 kg of sand, 15.68 kg of rock and 2.74 kg of water, 570.24 g of SP8 and 792 mL of the microcapsules from Example 1 were all contained in the concrete mix and injected into the beam mould. After one day, the samples were peeled from the molds and immersed in water for 14 days to fully cure.

[0098] Flexural strength test

[0099] The flexural strength program adopts ASTMC78 / C78M-10 and BS1881: Part118, and the sample size is 22.5cmx7.5cmx3.5cm. Each sample was subjected to an applied load of 0.50 mm / s in a four-point bending apparatus. Green strength is determined by applying a load to the sample to failure. To induce microcracks, samples were loaded to 80% of their initial strength, repaired for a few days, and tested again to failure again.

[0100] Such as Figure 8 As shown, the results for the initial sample an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com