Method for coproduction of coal-based synthetic oil and LNG (liquefied natural gas)

A technology for coal-based synthesis and synthesis gas, which is used in the preparation of liquid hydrocarbon mixtures, petroleum industry, waste fuels, etc., can solve the problem of methane not being recycled, and achieve the effect of reducing system energy consumption, meeting market requirements, and increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1, the method for coal-based synthetic oil co-production LNG

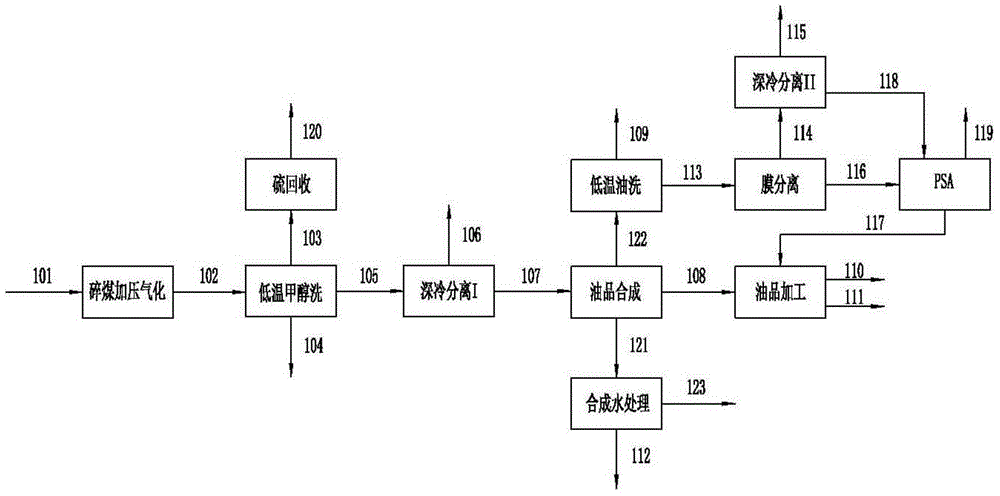

[0056] When the coal gasification unit adopts the pulverized coal pressurized gasification process, a process method of coal-based synthetic oil co-production LNG, such as figure 1 shown.

[0057] The specific process is as follows: Lump coal (101) is pressurized and gasified with crushed coal in a fixed bed (temperature: 1200°C, pressure: 4.5MPaG) to obtain crude gas (102), the main components of which are CO, H 2 、CH 4 , also including H 2 S, CO 2 , organic sulfur, tar, naphtha, phenol and ammonia and other impurities, among which CH 4 The content is 12mol%, H 2 / CO is 1.65. The crude gas (102) is first washed by low-temperature methanol in the pre-washing section (temperature: -40°C, pressure: 4.0MPaG) to remove naphtha in the gas to obtain naphtha (104), and then through the main washing section (temperature: -52°C, pressure: 4.0MPaG) to remove H 2 S, organic sulfur and CO 2 and other...

Embodiment 2

[0058] Embodiment 2, the method for coal-based synthetic oil co-production LNG

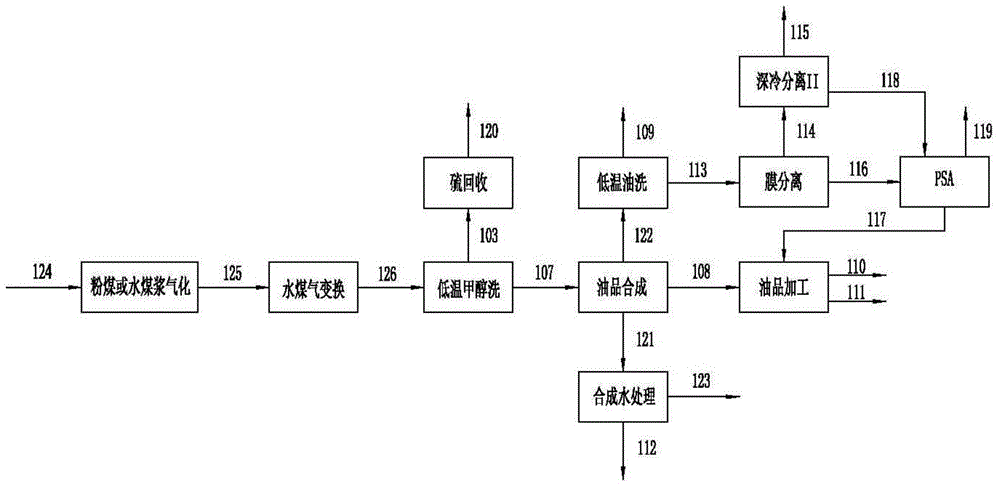

[0059] When the coal gasification unit adopts pulverized coal gasification or coal water slurry gasification process, another process method of coal-based synthetic oil co-production LNG, such as figure 2 shown.

[0060] The specific process is: pulverized coal (124) is gasified by pulverized coal or coal water slurry (temperature: 1350°C, pressure: 4.0MPaG) to obtain CO, H 2 Raw gas (125) as the main component, CH 4 Content 2 / CO ratio, H in the final shift gas (126) 2 The / CO ratio was 1.65. The shift gas (126) passes through the low-temperature methanol main washing section (temperature: -52°C, pressure: 3.4MPaG) to remove H 2 S, organic sulfur and CO 2 , the resulting F-T synthesis gas (107)CO 2 2 S+COS4 The content is 7mol%, and the oil-washed LPG (109) is obtained through the low-temperature oil washing unit, and the oil-washed dry gas (113) first enters the membrane separation device...

Embodiment 3

[0061] Embodiment 3, the method for coal-based synthetic oil co-production LNG

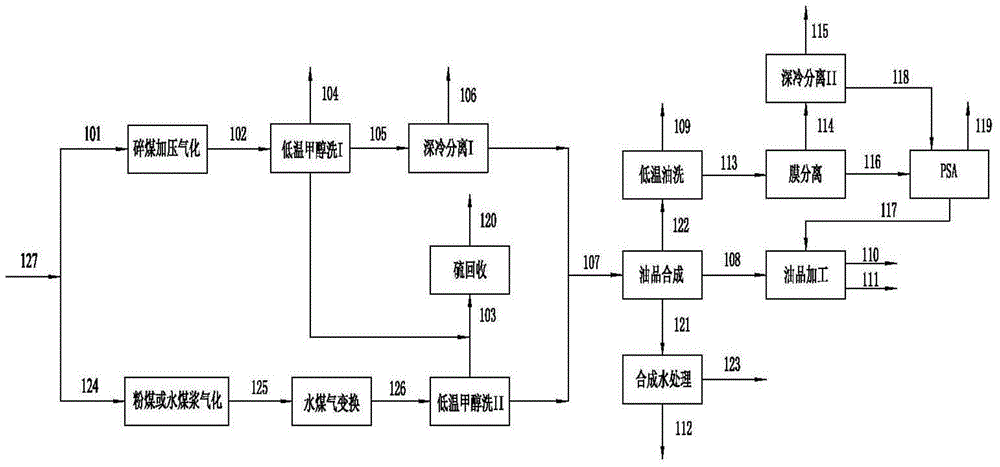

[0062] When the coal gasification unit adopts the double-gas head gasification process, a process method for the co-production of LNG with double-gas head coal-based synthetic oil, such as image 3 shown.

[0063] The lump coal (101) of the raw coal (127) enters the pulverized coal for pressurized gasification, and the pulverized coal (124) enters the pulverized coal or coal-water slurry gasification, and the distribution ratio of the raw coal can be adjusted according to the ratio of the final LNG product and oil product . When the raw coal (127) is 14.066 million tons / year, of which lump coal (101): pulverized coal (124) is 1:1, the final LNG product 1 (106) is 920 million Nm 3 / year, LNG product 2 (115) is 110 million Nm 3 / year, the final oil product gasoline (110)+diesel (111) is 2 million tons / year. The sulfuric acid-containing gas (103) obtained by the two gasification processes is mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com