Air-energy heat pump water heater

An air-energy heat pump and water heater technology, applied in heat pumps, fluid heaters, lighting and heating equipment, etc., can solve the problems of decreased heat exchange efficiency, shortened life, increased manufacturing costs, etc., and achieves improved water temperature and energy efficiency ratio. , the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment the content of the present invention will be further described:

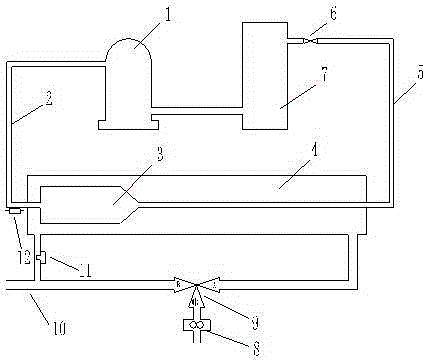

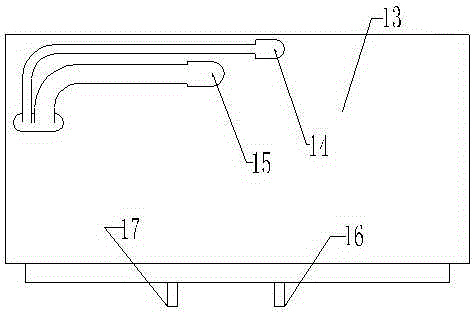

[0028] As shown in the figure, the working principle diagram of air energy heat pump water heater

[0029] The specific implementation is as follows:

[0030] 1. The refrigerant pipe in the heat exchange sleeve is worn in the middle of the water pipe, the heat exchange sleeve is coiled into a cylindrical shape, and it is placed outside the insulated inner tank of the water storage tank and in the insulation layer of the outer shell of the water storage tank. The heat exchange sleeve divides high-temperature heat energy The rapid convection release area is composed of two parts, the medium and low temperature heat energy slow liquefaction release area. The refrigerant pipe in the heat exchange sleeve in the high-temperature heat energy rapid convection release area is connected with the thinner metal pipe in the medium-low temperature heat ener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com