Synchrotron radiation X-ray large-area interference lithography system

A technology of interference lithography and X-rays, which is applied in the field of synchrotron radiation X-ray large-area interference lithography system, can solve the problems of not meeting technical requirements, limiting the effective exposure area and large-area splicing, and achieving the effect of ensuring alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

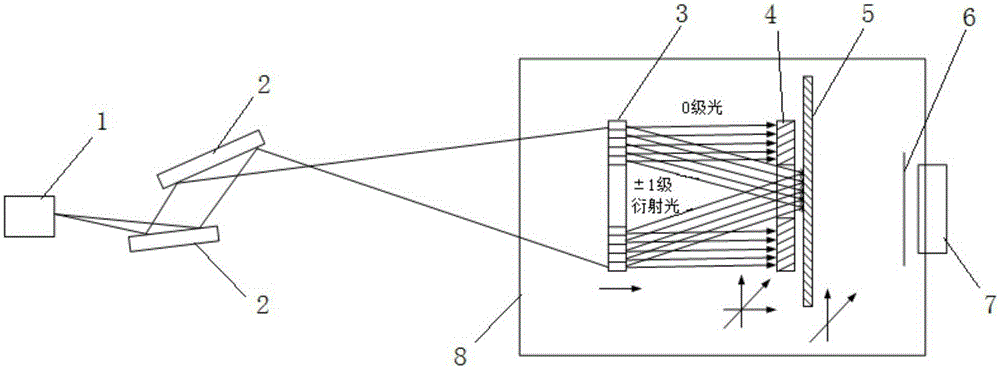

[0019] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

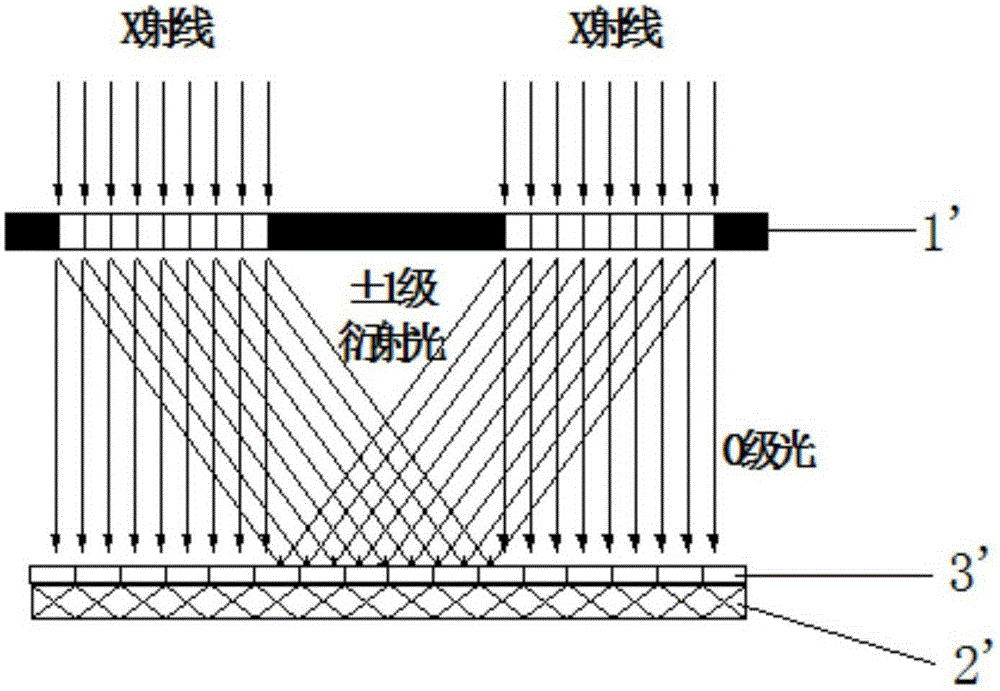

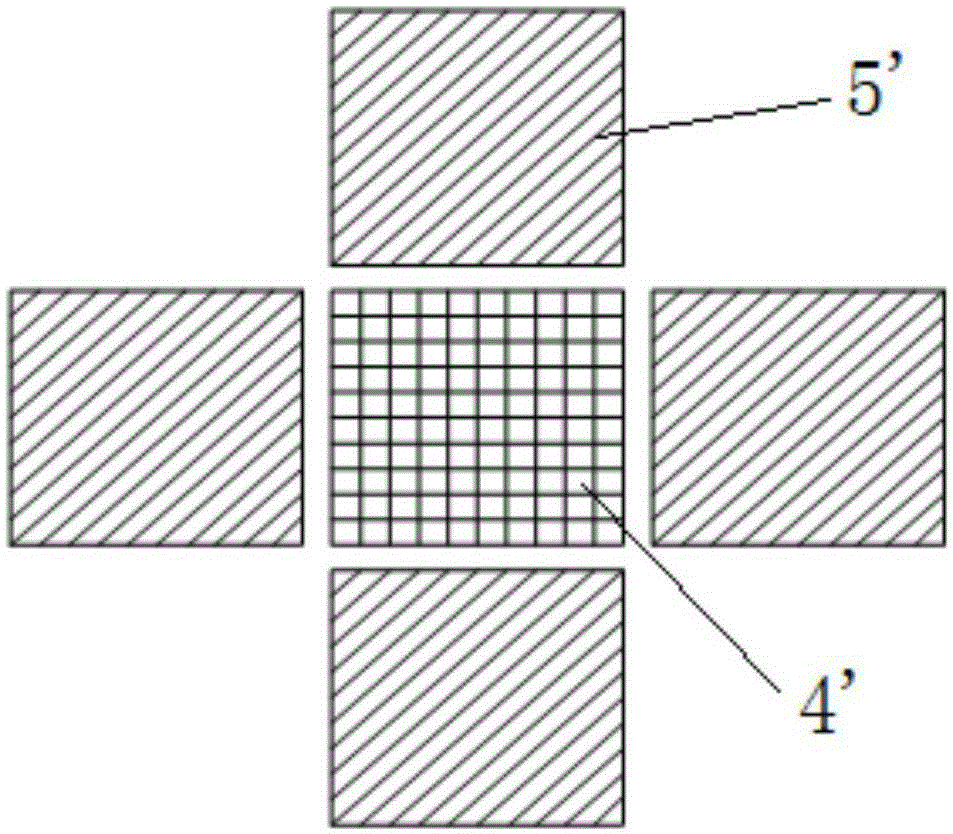

[0020] Such as image 3 As shown, the present invention, namely a kind of synchrotron radiation X-ray large-area interference lithography system, comprises: an undulator light source 1 arranged in sequence, a plurality of reflection focusing mirrors 2 (in this embodiment, the number of reflection focusing mirrors is 2), mask grating 3, gradation aperture 4 with aperture hole, sample stage 5 with observation hole, aluminum film 6 and CCD detector 7, also includes: first connected with gradation aperture 4 Mobile device (not shown in the figure) and the second mobile device (not shown in the figure) connected with sample stage 5; Wherein,

[0021] A plurality of reflective focusing mirrors 2 are configured to filter and transmit photons with energy above 1500eV in the X-ray emitted by the undulator light source 1 to the mask grating 3;

[0022] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com