Insect-preventing non-woven fabric

A non-woven fabric and insect-repelling technology, which is applied in the field of textile manufacturing, can solve the problems of easy failure of viscosity and limited degree of trapping and killing, and achieve the effects of stable process, low production cost and obvious insecticidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

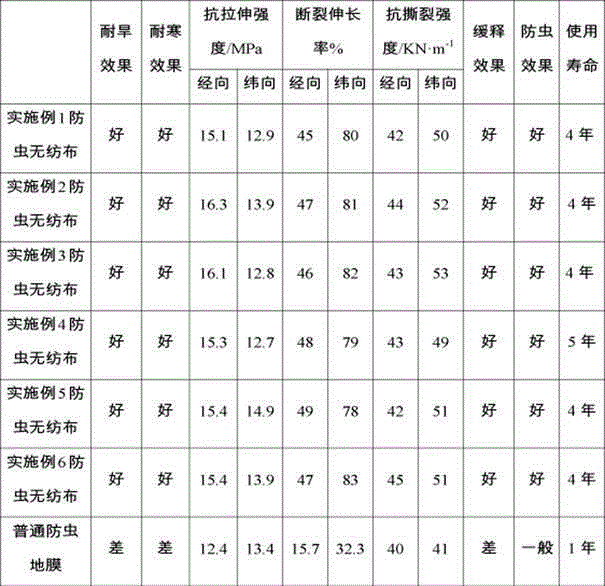

Examples

Embodiment 1

[0025] An anti-insect non-woven fabric, the composition of the anti-insect non-woven fabric includes 25kg of acrylate, 3kg of pyrethrin, 3kg of ethanol extract of tobacco, 4kg of turpentine, 3kg of aniseinin aqueous solution with a purity of 1%, and ethanol solution of neemin with a purity of 5%. 3kg, petroleum emulsion 3kg, sodium fluoride 3kg, sodium fluorosilicate 3kg, polypropylene 15kg, lignocellulose 20kg, nylon 30kg, polyester 25kg, insect-proof non-woven fabric is lignocellulose and insecticide bonded with acrylate Finally, it is compounded with polypropylene, nylon and polyester under high temperature conditions. The insect-proof non-woven fabric prepared under this condition has good insecticidal effect and long-lasting sustained release.

Embodiment 2

[0027] An anti-insect non-woven fabric, the composition of the anti-insect non-woven fabric includes 30 kg of acrylate, 5 kg of pyrethrin, 5 kg of ethanol extract of tobacco, 6 kg of turpentine, 5 kg of an anisein aqueous solution with a purity of 2%, and ethanol solution of neemin with a purity of 6%. 5kg, petroleum emulsion 5kg, sodium fluoride 5kg, sodium fluorosilicate 5kg, polypropylene 20kg, lignocellulose 35kg, nylon 35kg, polyester 30kg, insect-proof non-woven fabric is lignocellulose and insecticide bonded with acrylate Finally, it is compounded with polypropylene, nylon and polyester under high temperature conditions. The anti-insect non-woven fabric prepared under this condition has high tensile strength and stable quality.

Embodiment 3

[0029] An anti-insect non-woven fabric, the composition of the anti-insect non-woven fabric includes 20kg of acrylate, 1kg of pyrethrin, 1kg of ethanol extract of tobacco, 2kg of turpentine, 1kg of an anisein aqueous solution with a purity of 3%, and ethanol solution of neemin with a purity of 7%. 1kg, diesel emulsion 1kg, sodium fluoride 1kg, sodium fluorosilicate 1kg, polypropylene 10kg, lignocellulose 15kg, nylon 25kg, polyester 20kg, insect-proof non-woven fabric is made of lignocellulose and insecticide bonded with acrylate Finally, it is compounded with polypropylene, nylon and polyester under high temperature conditions. The insect-proof non-woven fabric prepared under this condition has a long service life and is durable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com