Amine modified fibrous membrane adsorption material and preparation method thereof

A technology of adsorption materials and fiber membranes, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problems of strong anti-interference ability of coexisting cations, difficult control of grafting and amination reactions, The problem of using a large amount of organic reagents, etc., achieves the effects of strong anti-interference ability of coexisting cations, easy control of amination process and yield, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

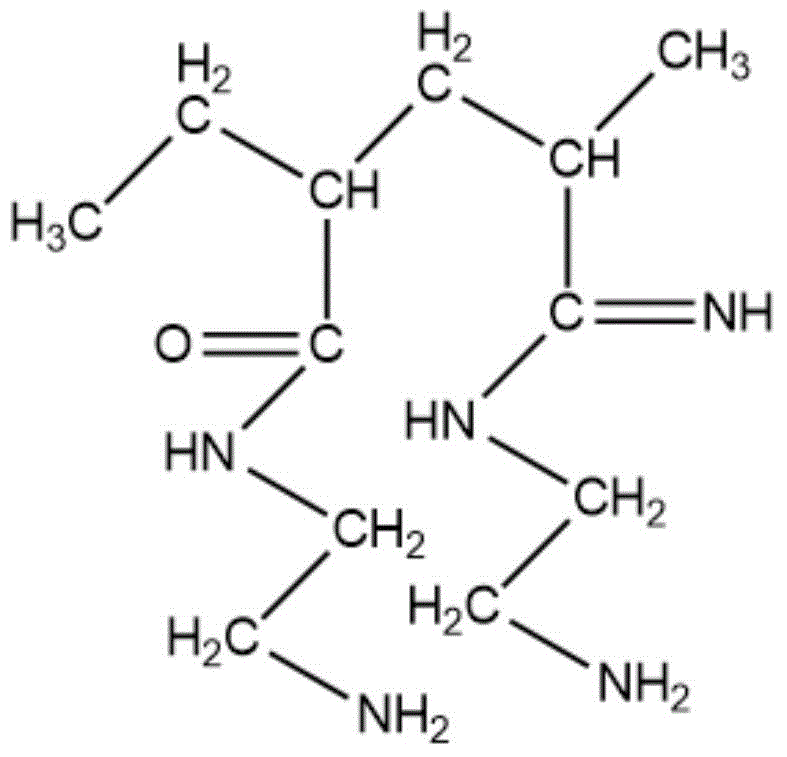

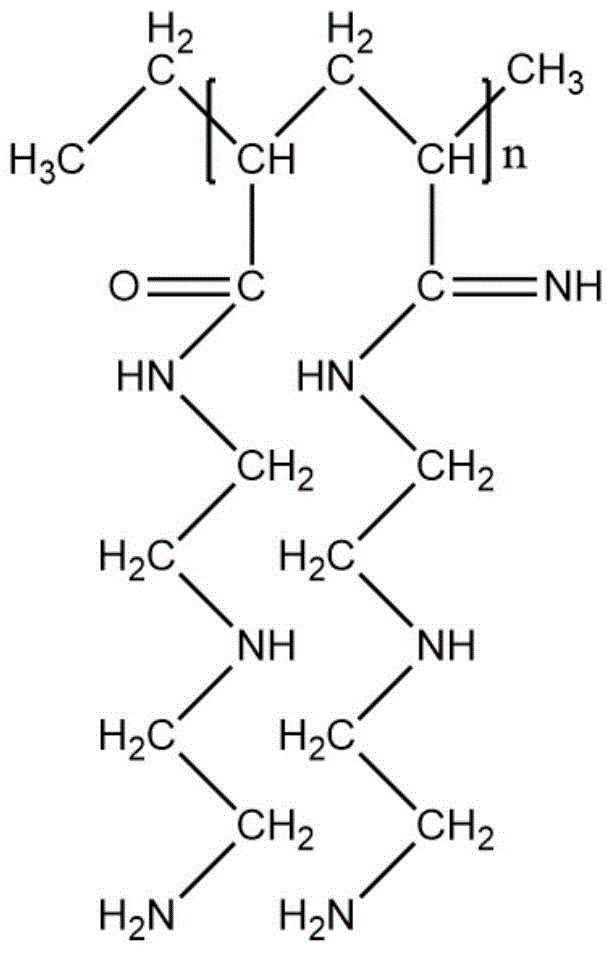

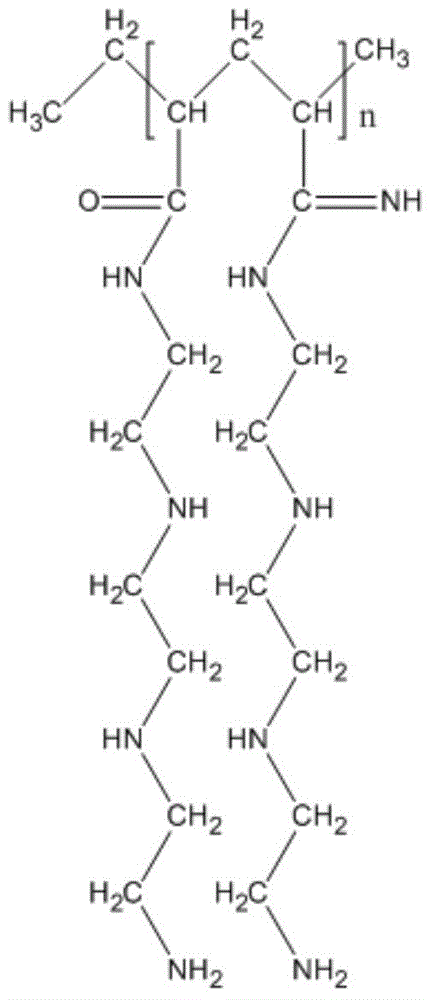

Method used

Image

Examples

Embodiment 1

[0047] A method for preparing an amine-modified fibrous membrane-like adsorbent, the steps comprising:

[0048] (1) Dissolve polyacrylonitrile and N,N-dimethylformamide DMF at a weight ratio of 1:3, stir and dissolve at 30°C for 5 hours, and the molecular weight of polyacrylonitrile is 85,000;

[0049] (2) Add the amination reaction reagent diethylenetriamine to the above solution, the mass ratio of polyacrylonitrile to the reaction reagent is 1:3, under the condition of stirring at 70°C and 200rpm, carry out the amination reaction for 2 hours, and obtain static electricity after cooling. Spinning liquid, move the liquid matrix into the syringe of the electrospinning machine, adjust the diameter of the spinneret, voltage, spinneret rate, humidity, receiving distance and drum speed, and perform electrospinning to obtain an amine-modified nanofiber membrane. Electrospinning process parameters are: voltage 10KV, nozzle aperture 0.4mm, solution flow rate 0.1mL / h, ambient temperatu...

Embodiment 2

[0061] A method for preparing an amine-modified fibrous membrane-like adsorbent, the steps comprising:

[0062] (1) Dissolve polyacrylonitrile and N,N-dimethylformamide DMF at a weight ratio of 1:4, stir and dissolve at 40°C for 8 hours, the concentration of the electrospinning solution is 20% by weight, polypropylene Nitrile has a molecular weight of 90,000.

[0063] (2) Add the amination reaction reagent diethylenetriamine to the above solution. The mass ratio of polyacrylonitrile to the reaction reagent is 1:3. Under the condition of stirring at 80°C and 200rpm, the amination reaction is carried out for 8h, and after cooling, static electricity is obtained. Spinning liquid, move the liquid matrix into the syringe of the electrospinning machine, adjust the diameter of the spinneret, voltage, spinneret rate, humidity, receiving distance and drum speed, and perform electrospinning to obtain an amine-modified nanofiber membrane. Electrospinning process parameters are: voltage ...

Embodiment 3

[0069] A method for preparing an amine-modified fibrous membrane-like adsorbent, the steps comprising:

[0070] (1) Dissolve polyacrylonitrile and N,N-dimethylformamide DMF at a weight ratio of 1:9, stir and dissolve at 40°C for 8 hours, the concentration of the electrospinning solution is 10% by weight, polypropylene Nitrile has a molecular weight of 95,000.

[0071] (2) Add the amination reaction reagent diethylenetriamine to the above solution, the mass ratio of polyacrylonitrile to the reaction reagent is 1:3, under the condition of stirring at 90°C and 200rpm, carry out the amination reaction for 12h, and obtain static electricity after cooling. Spinning liquid, move the liquid matrix into the syringe of the electrospinning machine, adjust the diameter of the spinneret, voltage, spinneret rate, humidity, receiving distance and drum speed, and perform electrospinning to obtain an amine-modified nanofiber membrane. Electrospinning process parameters are: voltage 16KV, nozz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com