Novel bismuth selenate photocatalyst, and preparation method and application thereof

A technology of photocatalyst and bismuth selenate, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of poor recyclability of reactors, rising production costs, complicated operation methods, etc., and achieve high Practical value and application prospect, strong regeneration ability, and the effect of high-efficiency decolorization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

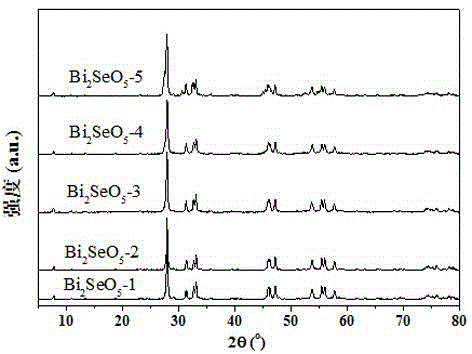

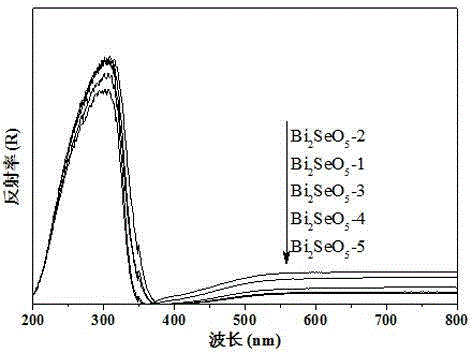

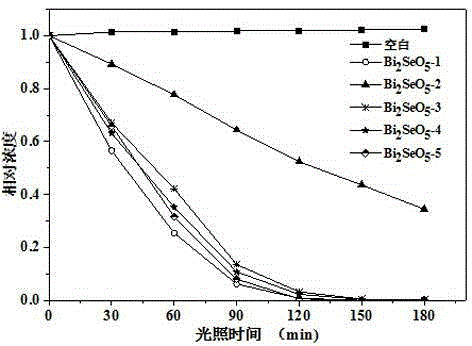

Embodiment 1

[0021] Dissolve 2mmol bismuth chloride, 3mmol selenium powder, 1.0g polyvinylpyrrolidone and 0.5g citric acid in 40mL deionized water, add NaOH solution with a concentration of 0.2mol / L under rapid stirring, adjust the pH value to 8, and continue stirring After 30 min, hydrothermally reacted at 210 °C for 24 h, then cooled to room temperature, centrifuged, the precipitate was washed with distilled water and absolute ethanol, and dried under vacuum at 80 °C to obtain Bi 2 Se 3 Precursor; Weigh 0.4gBi 2 Se 3 The precursor was placed in a crucible and placed in a muffle furnace, and calcined at 500 °C for 2 h in an air atmosphere to obtain Bi 2 SeO 5 Nanoparticles are bismuth selenate photocatalysts.

Embodiment 2

[0023] Dissolve 2mmol bismuth chloride, 3mmol selenium powder, 0.08g polyvinylpyrrolidone and 0.1g citric acid in 30mL deionized water, add NaOH solution with a concentration of 0.2mol / L under rapid stirring, adjust the pH value to 10, and continue stirring After 30 min, hydrothermally reacted at 210 °C for 24 h, then cooled to room temperature, centrifuged, the precipitate was washed with distilled water and absolute ethanol, and dried under vacuum at 80 °C to obtain Bi 2 Se 3 Precursor; weigh 1gBi 2 Se 3 The precursor was placed in a crucible and placed in a muffle furnace, and calcined at 300°C for 0.5h in an air atmosphere to obtain Bi 2 SeO 5 Nanoparticles are bismuth selenate photocatalysts.

Embodiment 3

[0025] Dissolve 2mmol bismuth chloride, 3mmol selenium powder, and 0.05g polyvinylpyrrolidone in 70mL deionized water, add NaOH solution with a concentration of 0.2mol / L under rapid stirring, adjust the pH value to 9, and continue stirring for 30min. The hydrothermal reaction was carried out at ℃ for 24 h, then cooled to room temperature, centrifuged, the precipitate was washed with distilled water and absolute ethanol, and vacuum-dried at 80 ℃ to obtain Bi 2 Se 3 Precursor; Weigh 0.5gBi 2 Se 3 The precursor was placed in a crucible and placed in a muffle furnace, and calcined at 400 °C for 4 h in an air atmosphere to obtain Bi 2 SeO 5 Nanoparticles are bismuth selenate photocatalysts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com