TiO2 catalyst with large specific surface area and visible-light response function and method for preparing TiO2 catalyst

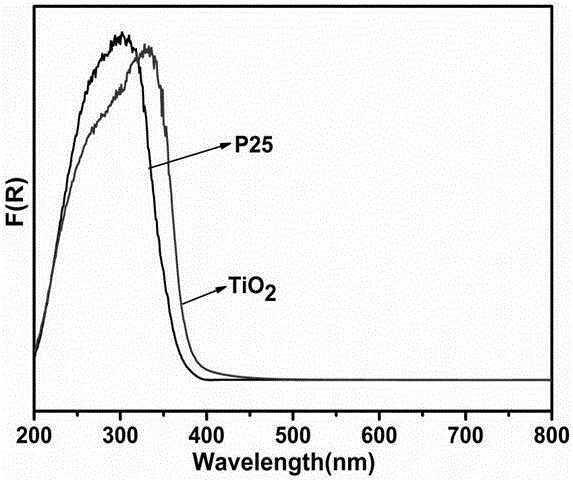

A technology with large specific surface area and visible light, applied in the field of photocatalysis, can solve problems such as low quantum efficiency, achieve good visible light photocatalytic performance, and improve the effect of visible light photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A Large Specific Surface Area-Visible Light Responsive TiO 2 The preparation method of catalyst, concrete steps are:

[0026] (1) MIL-125(Ti)-NH 2 The preparation method is as follows: Weigh 2-aminoterephthalic acid (1.2g) and disperse it in 36mL N,N-dimethylformamide (DMF) and anhydrous methanol (4mL), stir for 30min until the solute is fully dissolved and dispersed, Then use a pipette gun to pipette tetrabutyl titanate (1.2mL) into the reaction kettle, continue to stir for 30 minutes, put the kettle in a 150°C oven for 72 hours, cool naturally, exchange and wash with anhydrous methanol several times, and centrifuge. Then place the obtained sample in a vacuum oven at 60°C to dry, and the obtained yellow sample is MIL-125(Ti)-NH 2 ;

[0027] (2) With the synthesized MIL-125(Ti)-NH 2 As the precursor, weigh a certain amount of the precursor in the middle of the quartz tube of the tube furnace, and continue to pass nitrogen and oxygen, and calcined to a certain temper...

Embodiment 1

[0029] 1) Weigh 2-aminoterephthalic acid (1.2g) and disperse it in N,N-dimethylformamide (DMF) (36mL) and anhydrous methanol (4mL), stir for 30min until the solute is fully dissolved and dispersed, Then use a pipette gun to pipette tetrabutyl titanate (1.2mL) into the reaction kettle, continue to stir for 30 minutes, put the kettle in a 150°C oven for 72 hours, cool naturally, exchange and wash with anhydrous methanol several times, and centrifuge. Then place the obtained sample in a vacuum oven at 60°C to dry, and the obtained yellow sample is MIL-125(Ti)-NH 2 ;

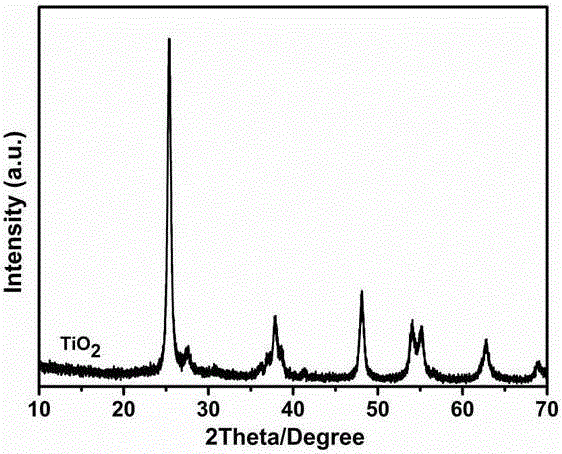

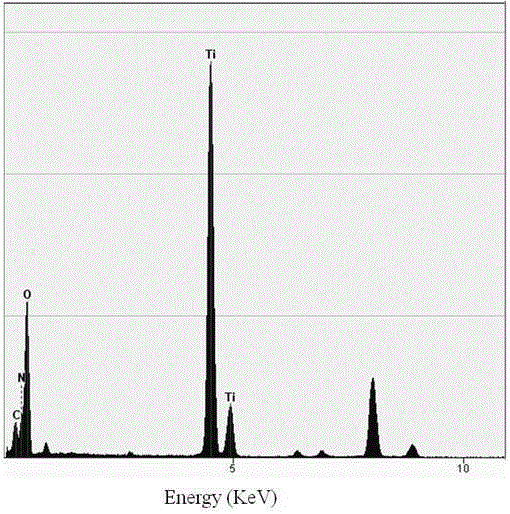

[0030] 2) Place the obtained sample in the middle of the quartz tube of the tube furnace for calcination, continuously pass nitrogen and oxygen, the nitrogen flow rate is 50ml / min, the oxygen flow rate is 5ml / min, the calcination temperature is 500°C, and the heating rate is 1°C per minute. The constant temperature holding time is 3 hours, and the calcined product is cooled with the furnace at a rate of 3°C per min...

Embodiment 2

[0032] 1) Weigh 2-aminoterephthalic acid (1.2g) and disperse it in DMF (36mL) and anhydrous methanol (4mL), stir for 30min until the solute is fully dissolved and dispersed, then pipette tetrabutyl titanate with a pipette gun Put the ester (1.2mL) into the reaction kettle, continue to stir for 30min, place it in a 150°C oven to react for 72h, cool naturally, wash with anhydrous methanol several times, centrifuge, and then place the obtained sample in a 60°C vacuum oven to dry dry, the resulting yellow sample is MIL-125(Ti)-NH 2 ;

[0033]2) Place the obtained sample in the middle of the quartz tube of the tube furnace for calcination, continuously pass nitrogen and oxygen, the nitrogen flow rate is 50ml / min, the oxygen flow rate is 10ml / min, the calcination temperature is 550°C, and the heating rate is 1°C per minute. The constant temperature holding time is 3 hours, and the calcined product is cooled with the furnace at a rate of 3°C per minute, and cooled to room temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com