Silicon removal method of low-grade bauxite

A bauxite and desiliconization technology, applied in the direction of alumina/hydroxide, etc., can solve the problems of poor comprehensive benefits, complex production process, high production cost, etc., to improve the ratio of aluminum to silicon, fully desiliconize the reaction, increase contact the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

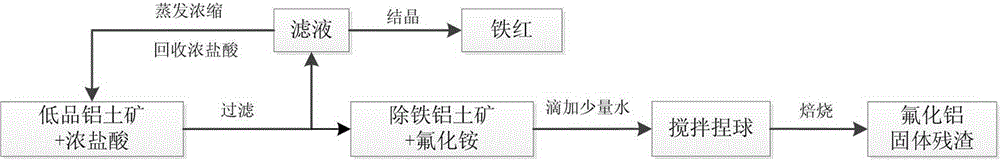

[0023] see figure 1 , the invention provides a method for desiliconization of low-grade bauxite, comprising the following steps:

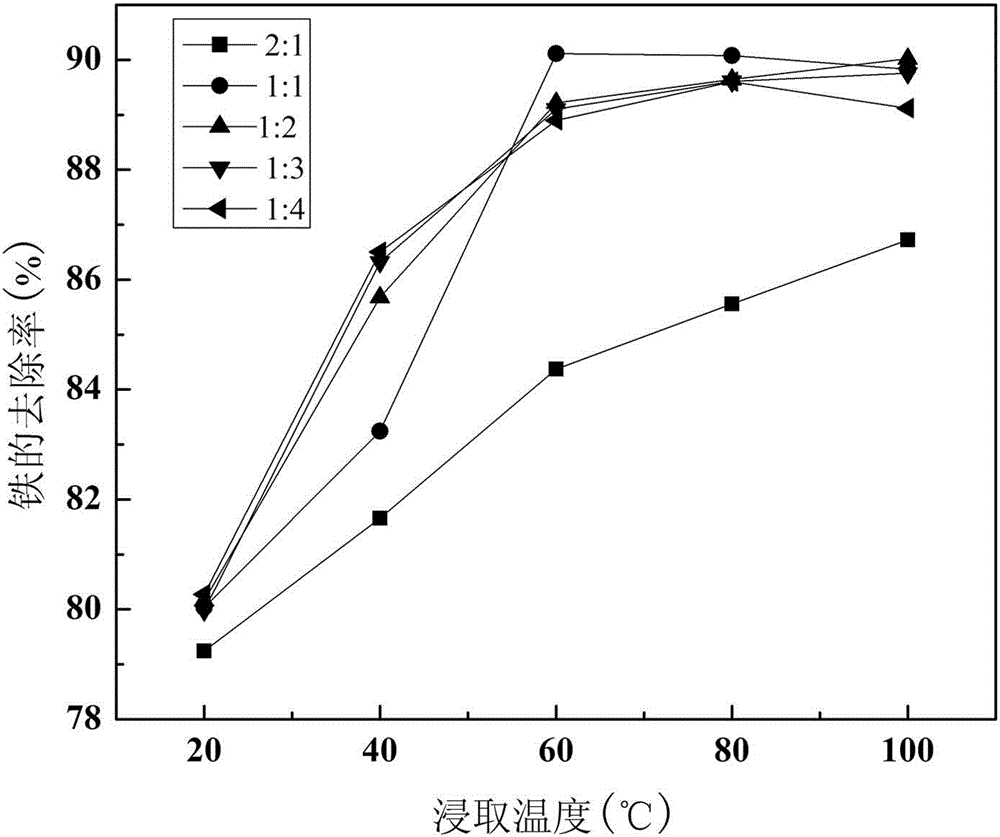

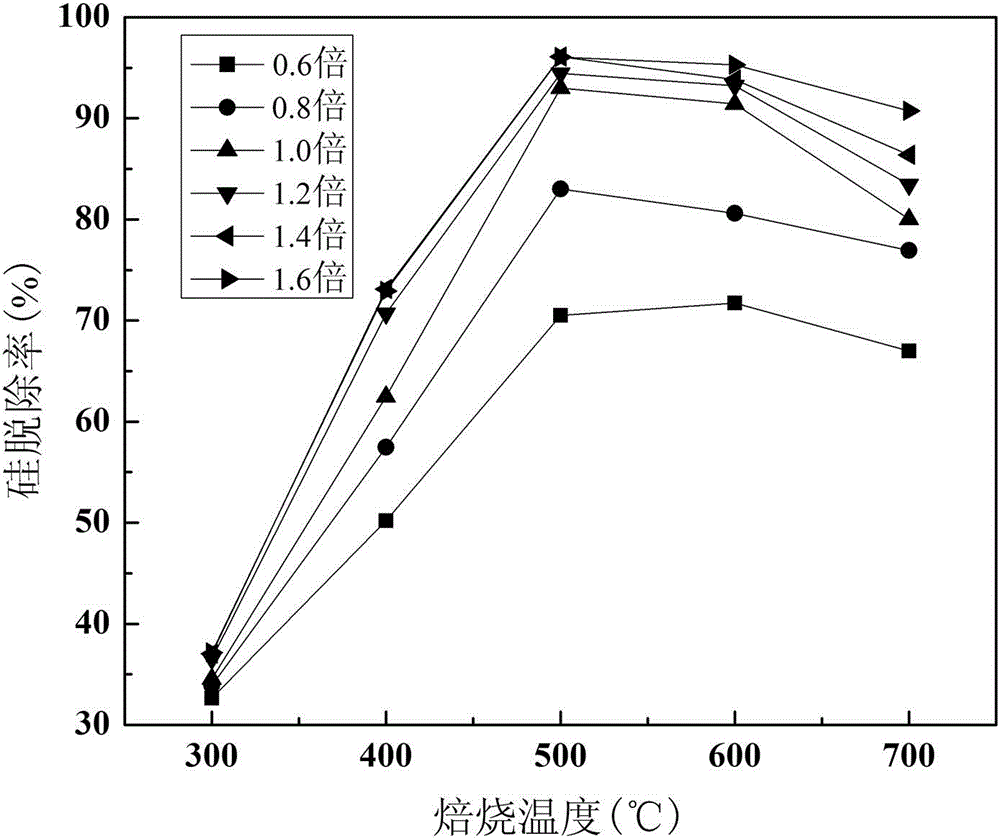

[0024] Acid leaching and iron removal: reacting hydrochloric acid in low-grade bauxite particles to form acid leaching slurry; filtering the acid leaching slurry to obtain leaching solution and iron-removing filter residue; drying the iron-removing filter residue to obtain iron-removing bauxite. Specifically, add concentrated hydrochloric acid to the low-grade bauxite particles according to the ratio of 1-1.4mL concentrated hydrochloric acid / 1g low-grade bauxite, and react at 40-80°C for 20-40min to form the acid leaching slurry, wherein the volume fraction of the concentrated hydrochloric acid is 36% to 38%; adding water to dilute the acid leaching slurry to obtain a dilute acid leaching slurry; using a filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com