Cement grinding aid and preparation method thereof

A technology of cement grinding aids and high-efficiency water reducers, applied in the field of cement grinding aids, can solve the problems of restricting the popularization of industrialization and high production costs, and achieve the effects of reducing production costs, reducing dosage, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

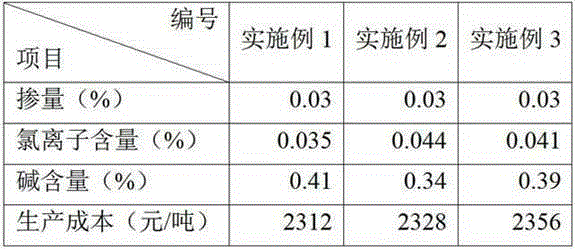

Embodiment 1

[0018] Embodiment 1: Preparation of cement grinding aid.

[0019] First add 300kg triethanolamine in the reaction kettle, then add 500kg Glauber's salt, 300kg industrial salt, 100kg sodium nitrite, 100kg sodium thiosulfate, 200kg sodium acetate and 100kg sodium thiocyanate successively, stir 30min under 150rpm rotating speed, heat to 80°C and keep warm for 4h, then add 100kg triethanolamine, 100kg ethylene glycol, 50kg glycerol, 50kg polyethylene glycol 400, 100kg ASPF-Na and 100kg colloidal silicon dioxide in sequence, and continue to keep warm and stir for 30min, stop heating and Stir and discharge when the temperature drops to 40°C to obtain the required cement grinding aid.

Embodiment 2

[0020] Embodiment 2: Preparation of cement grinding aid.

[0021] First add 500kg triethanolamine in the reactor, then add 700kg Glauber's salt, 500kg industrial salt, 150kg sodium nitrite, 150kg sodium thiosulfate, 300kg sodium acetate and 150kg sodium thiocyanate successively, stir 40min under 140rpm rotating speed, heat to 70°C and keep warm for 5h, then add 100kg triethanolamine, 150kg ethylene glycol, 70kg glycerol, 70kg polyethylene glycol 400, 150kg ASPF-Na and 150kg colloidal silicon dioxide in sequence, and continue to keep warm and stir for 40min, stop heating and Stir and discharge when the temperature drops to 40°C to obtain the required cement grinding aid.

Embodiment 3

[0022] Embodiment 3: Preparation of cement grinding aid.

[0023] First add 400kg triethanolamine in the reactor, then add 600kg Glauber's salt, 400kg industrial salt, 125kg sodium nitrite, 125kg sodium thiosulfate, 250kg sodium acetate and 125kg sodium thiocyanate successively, stir 40min under 150rpm rotating speed, heat to 80°C and keep warm for 5h, then add 100kg triethanolamine, 125kg ethylene glycol, 60kg glycerol, 60kg polyethylene glycol 400, 125kg ASPF-Na and 125kg colloidal silicon dioxide in sequence, and continue to keep warm and stir for 30min, stop heating and Stir and discharge when the temperature drops to 40°C to obtain the required cement grinding aid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com