A kind of vinyl resin for large-scale lead-acid battery tank and preparation method thereof

A vinyl resin and lead-acid battery technology, applied in the field of polymer materials, can solve problems such as elastic modulus, low strength, battery performance degradation, battery tank deformation, etc., achieve fast curing speed, improve heat resistance, and acid resistance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

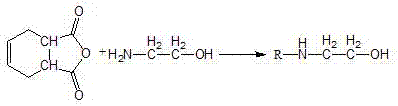

[0028] Put tetrahydrophthalic anhydride into the reaction kettle, start stirring, N 2 For protection, add ethanolamine in an equimolar amount, close the feeding port, control the temperature at 80-100°C, and the reaction time is 8 hours.

[0029] Put imino alcohol and maleic anhydride in equimolar ratio into the reaction kettle, catalyzed by concentrated sulfuric acid, the reaction temperature is 60°C, and the reaction time is 4 hours to generate maleic imide ester.

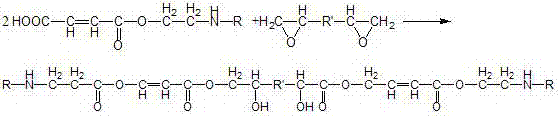

[0030] Put the maleic acid imide ester into the reaction kettle, raise the temperature to 80°C, add benzyldimethylamine and hydroquinone, use them as catalyst and polymerization inhibitor respectively, and add bisphenol A epoxy resin in batches , the molar ratio of maleic acid imide ester and bisphenol A epoxy resin is 2:1, the temperature is raised to 120-140°C, the reaction time is 4-6 hours, and the acid value is controlled at 10-15mgKOH / g, It is a vinyl resin with imine groups. When the temperature drops bel...

Embodiment 2

[0034] Put tetrahydrophthalic anhydride into the reaction kettle, start stirring, N 2 For protection, add ethanolamine in an equimolar amount, close the feeding port, control the temperature at 80-100°C, and the reaction time is 8 hours.

[0035] Put imino alcohol and maleic anhydride in equimolar ratio into the reaction kettle, catalyzed by concentrated sulfuric acid, the reaction temperature is 60°C, and the reaction time is 4 hours to generate maleic imide ester.

[0036] Put the maleic acid imide ester into the reaction kettle, raise the temperature to 80°C, add benzyldimethylamine and hydroquinone, use them as catalyst and polymerization inhibitor respectively, and add bisphenol A epoxy resin in batches , the molar ratio of maleic acid imide ester and bisphenol A epoxy resin is 2:1, the temperature is raised to 120-140°C, the reaction time is 4-6 hours, and the acid value is controlled at 10-15mgKOH / g, It is a vinyl resin with imine groups. When the temperature drops bel...

Embodiment 3

[0040] Put tetrahydrophthalic anhydride into the reaction kettle, start stirring, N 2 For protection, add ethanolamine in an equimolar amount, close the feeding port, control the temperature at 80-100°C, and the reaction time is 8 hours.

[0041] Put imino alcohol and maleic anhydride in equimolar ratio into the reaction kettle, catalyzed by concentrated sulfuric acid, the reaction temperature is 60°C, and the reaction time is 4 hours to generate maleic imide ester.

[0042] Put the maleic acid imide ester into the reaction kettle, raise the temperature to 80°C, add benzyldimethylamine and hydroquinone, use them as catalyst and polymerization inhibitor respectively, and add bisphenol A epoxy resin in batches , the molar ratio of maleic acid imide ester and bisphenol A epoxy resin is 2:1, the temperature is raised to 120-140°C, the reaction time is 4-6 hours, and the acid value is controlled at 10-15mgKOH / g, It is a vinyl resin with imine groups. When the temperature drops bel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com