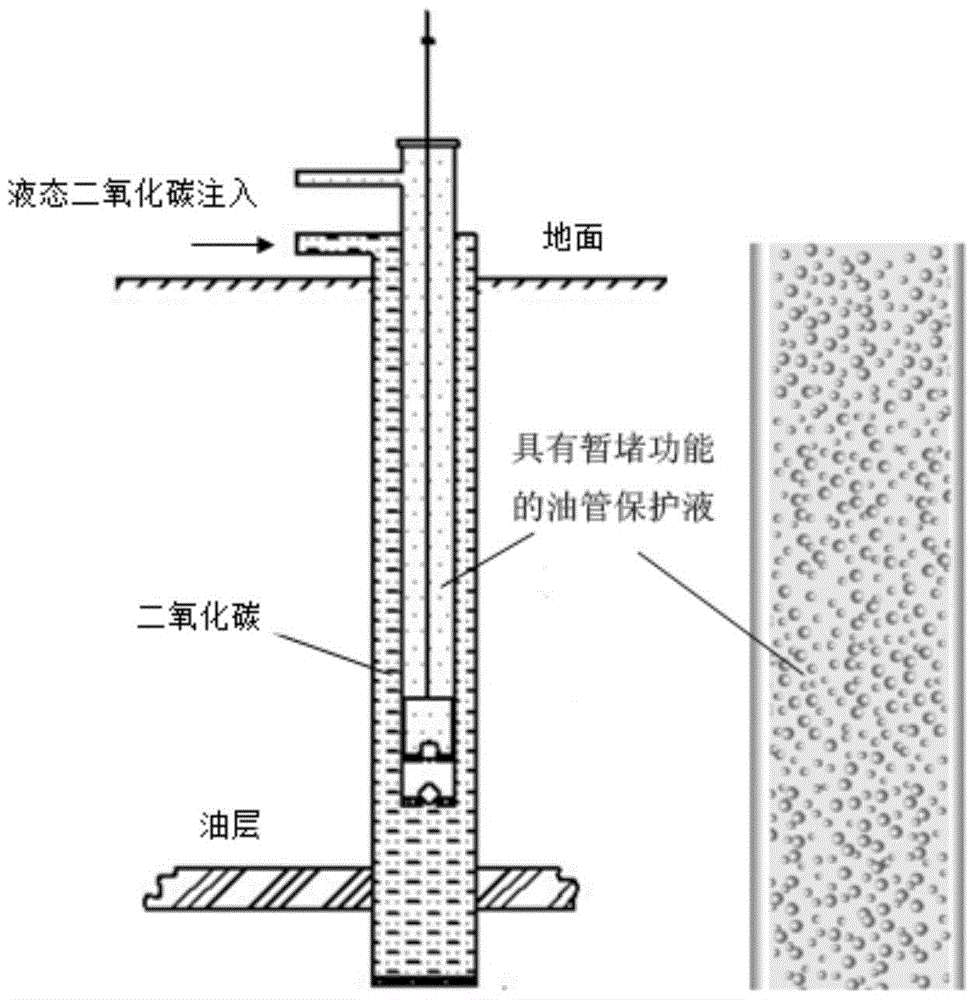

Oil pipe protection fluid with temporary plugging function, preparation method and application thereof

A technology for protecting fluids and oil pipes, which is applied in chemical instruments and methods, earthwork drilling, drilling compositions, etc., can solve the problems of carbon dioxide huff and puff effect, increased operating costs, increased operating costs, etc., and achieves controllable degradation time. , Good temporary blocking function, fast blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment provides an oil pipe protection liquid with a temporary plugging function. Based on the total weight of the oil pipe protection liquid with a temporary plugging function as 100%, the oil pipe protection liquid with a temporary plugging function is composed of 76.6% by weight. Water, 0.2% sodium carbonate, 0.05wt% sodium hydroxide, 0.1wt% methanol, 0.2wt% 2,2,4-trimethylpentane, 0.4wt% D-glucuronic acid, 0.05wt % Sodium lauryl sulfate, 1.5% by weight polyanionic cellulose, 0.3% by weight carboxymethyl cellulose, 0.3% by weight methyl tert-butyl ether, 0.3% by weight sulfamic acid, 15% by weight It is prepared from sodium chloride and 5wt% potassium chloride.

Embodiment 2

[0025] This embodiment provides the preparation method of the oil pipe protection liquid with temporary plugging function of embodiment 1, wherein the preparation method includes the following steps:

[0026] a. Add water to the mixing container under normal temperature and stir; according to the ratio of each component in the oil pipe protection solution with temporary plugging function provided in Example 1, add sodium carbonate, sodium hydroxide, methanol, 2, 2, 4 -Trimethylpentane, D-glucuronic acid, sodium lauryl sulfate, polyanionic cellulose, carboxymethyl cellulose, methyl tert-butyl ether (MTBE), sulfamic acid are added to the mixing container in order After stirring for 90 minutes, solution A is obtained;

[0027] b. Add sodium chloride and potassium chloride to the above solution A and stir for 20 minutes to obtain the oil pipe protection solution with temporary plugging function.

Embodiment 3

[0029] This embodiment provides an oil pipe protection liquid with temporary plugging function. Taking the total weight of the oil pipe protection liquid with temporary plugging function as 100%, the oil pipe protection liquid with temporary plugging function is composed of 76.72wt% Water, 0.3wt% sodium carbonate, 0.08wt% sodium hydroxide, 0.2wt% methanol, 0.1wt% 2,2,4-trimethylpentane, 0.3wt% D-glucuronic acid, 0.1 wt% sodium lauryl sulfate, 1.3 wt% polyanionic cellulose, 0.4 wt% carboxymethyl cellulose, 0.2 wt% methyl tert-butyl ether (MTBE), 0.4 wt% sulfamic acid , 10wt% sodium chloride and 10wt% potassium chloride are prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com